Sharp corners in injection molding lead to stress concentrations, material defects, and reduced product longevity.

Fundamentals of Mold Design

Understanding the fundamentals of mold design is crucial for successful injection molding. The design process involves multiple considerations, including the shape and features of the product, the type of plastic material, and the specifics of the molding machine. Efficient mold design ensures not only the quality of the final product but also contributes to the smooth operation and cost-effectiveness of the production process.

Basic Principles of Mold Design

In the realm of mold design, some key principles stand out. The design must facilitate easy ejection, cooling, and filling of the mold. It’s essential to balance these requirements:

- Uniform Wall Thickness: Maintaining uniform wall thickness promotes even cooling and reduces defects like warping or shrinkage. Wall Thickness is a fundamental concept in mold design.

- Adequate Draft Angles: Draft angles help in the easy ejection of the final product from the mold. A lack of proper draft can lead to scraping or damage to the product’s surface.

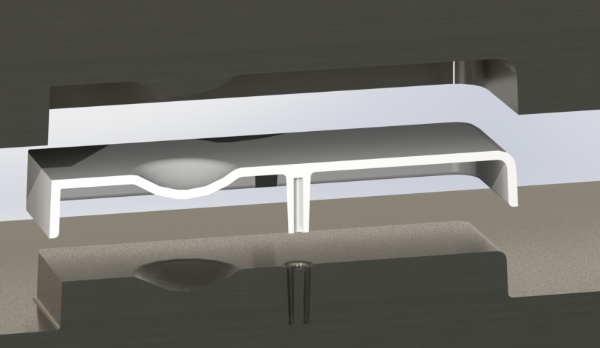

- Gating System Design: The gating system, which includes runners, gates, and risers, must ensure efficient material flow and minimize waste. Gating System design impacts the overall quality of the product.

The Role of Geometry in Mold Design

Geometry plays a pivotal role in mold design, influencing both the manufacturability and functionality of the product.

- Complex Shapes and Features: Advanced geometric designs can enhance product functionality but may introduce challenges in mold design, like uneven cooling or difficulty in mold filling.

- Surface Finish: The geometry of the mold also dictates the surface finish of the product, which is crucial for both aesthetic and functional purposes.

- Tolerance and Precision: Geometric precision is vital, especially for parts that must fit together. Tolerances must be carefully considered in the design phase to ensure the final product meets the required specifications.

Common Mold Design Challenges

Several challenges commonly arise in mold design, often related to material selection, part geometry, and the intended use of the product:

- Material Behavior: Different materials have unique flow characteristics, cooling rates, and shrinkage factors, all of which affect the mold design. Understanding the behavior of Plastic Materials is key.

- Shrinkage and Warping: Uneven cooling can lead to shrinkage and warping, compromising the integrity and dimensions of the final product.

- Tooling Costs and Lifespan: Balancing the cost of mold production with the expected lifespan and the number of usable parts the mold can produce is a crucial economic consideration.

Implications of Sharp Corners in Injection Molds

Sharp corners in injection molds can significantly impact the manufacturing process and the quality of the final product. These implications range from creating stress concentrations in the molded parts to affecting the overall lifespan and maintenance costs of the mold itself. Understanding these effects is crucial for optimizing design, enhancing the durability of both the mold and the molded product, and ensuring cost-effective operation.

Stress Concentration and Material Weakness

Sharp corners in a mold lead to areas of high stress concentration in the finished product. These high-stress areas can become weak points, making the product more susceptible to:

- Cracking and Breakage: Stress concentrations can cause parts to crack or break under normal use, significantly reducing their lifespan. For instance, a plastic part with sharp internal corners might only withstand half the mechanical stress of a similar part with rounded corners before failing.

- Reduced Tolerance to Load: Products with stress concentrations typically have a lower tolerance to mechanical loads, impacting their performance and reliability.

- Material Selection Constraints: Certain materials, particularly brittle plastics like polystyrene or acrylic, are more sensitive to stress concentrations. Designers often need to choose more durable, and sometimes more expensive, materials to compensate for design limitations.

Effects on Material Flow and Cooling

The flow of molten plastic and its cooling pattern within the mold is critical to the quality of the final product. Sharp corners can adversely affect these processes:

- Uneven Material Flow: Sharp corners can obstruct the smooth flow of molten plastic, leading to defects like weld lines, air traps, and incomplete filling.

- Differential Cooling Rates: Sharp corners can cause uneven cooling, leading to internal stresses, warpage, and dimensional inaccuracies. The cooling time in a mold directly impacts cycle time and productivity. A part with a uniform thickness of 2mm might cool and solidify in approximately 6 seconds, whereas the same plastic at 4mm thickness could require over 15 seconds.

Impact on Mold Lifespan and Wear

The design of the mold influences its lifespan and maintenance costs:

- Increased Wear and Tear: Sharp corners in molds are prone to wear out more quickly, leading to increased maintenance costs. For example, a mold designed with rounded corners might produce up to 500,000 cycles before needing significant maintenance, while a mold with sharp corners may require attention after just 300,000 cycles.

- Tooling Costs: Molds with sharp corners often require more complex and precise machining, which can increase tooling costs. The cost of manufacturing a complex mold with sharp corners can be up to 20-30% higher than one with smoother, rounded geometries.

- Repair and Maintenance: Maintenance costs for molds with sharp corners are higher. If the maintenance frequency for a standard mold is every 100,000 cycles, a mold with sharp corners might need servicing every 70,000 cycles, increasing downtime and production costs.

Design Alternatives to Sharp Corners

In the world of injection molding, addressing the issues caused by sharp corners is crucial for the longevity and functionality of both the mold and the molded part. Designers and engineers often resort to various alternatives, such as incorporating radii, fillets, and rounds, to mitigate the risks associated with sharp corners. These design changes not only enhance the strength and integrity of the product but also contribute to more efficient and cost-effective manufacturing processes.

The Benefits of Using Radii

Incorporating radii in place of sharp corners can lead to significant improvements:

- Increased Strength and Durability: Parts with radii can distribute stress more evenly, thereby enhancing strength and resistance to cracking. For example, a radius of just 1mm can often increase the strength at a corner by over 40% compared to a sharp corner.

- Improved Material Flow: Radii facilitate smoother flow of the molten material during the injection process, reducing the likelihood of defects such as air traps or voids. This smoother flow allows for faster filling times and shorter cycle times, indirectly contributing to higher production efficiency.

- Reduced Wear on the Mold: Molds with radii experience less wear and tear, thereby increasing their lifespan. This design change can extend the life of a mold by up to 25%, reducing the need for frequent repairs or replacements.

Implementing Fillets and Rounds

Adding fillets and rounds is a practical approach to eliminating sharp corners in mold design:

- Enhanced Product Aesthetics: Fillets and rounds can contribute to a more aesthetically pleasing product, which is particularly important in consumer goods.

- Minimized Stress Concentration: Fillets, which are curved junctions between two surfaces, can significantly reduce stress concentrations. A well-designed fillet can reduce stress concentration by up to 50%.

- Cost-Effective Manufacturing: While the inclusion of fillets might slightly increase the complexity of the mold design, this is often offset by reduced production issues and lower reject rates. The increase in tooling cost is typically around 5-10%, a reasonable trade-off for improved product quality and reduced risk.

Case Studies: Success Stories in Rounded Designs

Various industries have seen remarkable improvements by shifting from sharp to rounded corner designs:

- Automotive Industry: In the automotive sector, manufacturers have observed a reduction in material failure rates by integrating rounded corners in parts subjected to high stress, like brackets and mounts. This change not only improves safety but also enhances the overall lifespan of these components.

- Consumer Electronics: A famous example is the transition in smartphone designs from sharp to more rounded corners, significantly improving their structural integrity and resistance to impact. This design change contributed to a decrease in screen cracking incidents by nearly 30%.

- Medical Devices: In medical device manufacturing, rounded corners have reduced the risk of stress cracking in sterilizable components, leading to more reliable and safer products.

Practical Considerations in Avoiding Sharp Corners

Incorporating design strategies to avoid sharp corners in injection molding is not only about enhancing product quality and longevity; it’s also about understanding the implications on material choice, mold manufacturing techniques, and recognizing the inherent design trade-offs. Thoughtful consideration of these factors ensures the creation of efficient, cost-effective, and high-quality molds and products.

Material Selection and its Influence

The choice of material plays a significant role in determining the feasibility and effectiveness of avoiding sharp corners in molded parts:

- Material Behavior: Different materials have varying levels of flexibility, strength, and stress tolerance. For instance, materials like ABS or polycarbonate allow for smaller radii due to their higher flexibility, whereas more rigid materials might require larger radii to avoid cracking.

- Thermal Properties: Materials with different thermal expansion rates or cooling behaviors might affect how sharp corners in the mold behave. Materials with high thermal expansion coefficients might necessitate larger radii to accommodate for expansion and contraction during the molding and cooling processes.

- Cost Implications: Selecting a material that can handle smaller radii or complex shapes might increase the material cost. For example, using high-flexibility plastics might increase material costs by up to 20% compared to standard plastics.

Mold Manufacturing Techniques

The method used to create the mold directly affects the ability to design out sharp corners:

- CNC Machining: CNC machining offers high precision in creating rounded corners and complex shapes but might increase the mold manufacturing cost due to the intricacies involved. The cost can be higher by approximately 15-30% compared to standard mold machining processes.

- EDM (Electrical Discharge Machining): EDM is particularly useful for creating detailed features like small radii in hard materials but can be slower and more costly. However, the precision it offers often outweighs the increase in production time and cost, especially for high-precision components.

Limitations and Design Trade-offs

While avoiding sharp corners is beneficial, there are certain limitations and trade-offs to consider:

- Design Complexity: Implementing radii or curved features can add complexity to the product design, potentially impacting the ease of manufacturing and assembly. This complexity might lead to a 10-15% increase in overall design time.

- Aesthetic Impact: In some products, especially consumer goods, the aesthetic of the product might be impacted by the need to include larger radii or rounded features. Designers must balance functional integrity with visual appeal.

- Functional Limitations: In some cases, the function of the part might dictate the presence of sharp corners or specific angles, thus limiting the ability to modify these features. Designers must then focus on optimizing the material choice and mold design to mitigate the risks involved.