Extrusion manufacturing is popular due to its cost-effectiveness, versatility, and ability to produce high-quality, consistent products across various industries.

Fundamental Advantages

Extrusion manufacturing has become a cornerstone in multiple industries for a variety of reasons. The method brings a host of advantages to the table, making it an attractive choice for manufacturers.

Cost-Effectiveness

One of the most compelling reasons for the popularity of extrusion manufacturing is its cost-effectiveness. By using a continuous process, extrusion manufacturing minimizes material waste, thereby reducing material costs.

- Material Savings: The process is highly material-efficient, which significantly reduces costs.

- Reduced Labor Costs: Automation in extrusion processes minimizes the need for manual labor.

- Economies of Scale: Higher volumes typically lead to lower per-unit costs.

Relevant Information: Extrusion Wikipedia

Efficiency

Efficiency is another major draw. The extrusion process is often quicker than alternative manufacturing processes like injection molding or milling, especially when you’re dealing with high volumes.

- Speed: Rapid throughput times enable quick production cycles.

- Less Downtime: The continuous nature of the process allows for less machine downtime.

- Simplified Post-Processing: Many extrusion processes require less post-processing, saving both time and resources.

Versatility

Extrusion manufacturing stands out for its versatility. The process can handle a wide range of materials and produce a broad spectrum of products with complex geometries.

- Variety of Materials: Metals, plastics, and even food products can be extruded.

- Complex Shapes: The method can create intricate shapes that are difficult to achieve with other manufacturing techniques.

- Adaptability: Easily changeable dies make the system adaptable to multiple applications.

Material Options

Extrusion manufacturing excels in its ability to work with a variety of materials. This adaptability enables the creation of specialized products for multiple industries. Below we explore some of the most commonly used materials.

Plastics

- Polyethylene: Widely used for making bottles, containers, and other packaging materials.

- Polypropylene: Often used for automotive components and consumer goods.

- PVC: Commonly used for pipes and tubing in the construction sector.

Relevant Information: Plastics Wikipedia

Metals

Metal extrusion offers the benefit of producing strong and durable products.

- Aluminum: Known for its light weight and corrosion resistance, often used in aerospace and automotive industries.

- Copper: Commonly used for electrical applications due to its excellent conductivity.

- Steel: Widely used in construction for its strength and durability.

Rubber

- Natural Rubber: Offers excellent flexibility and is often used in seals and gaskets.

- Silicone Rubber: Known for its resistance to extreme temperatures, commonly used in automotive and medical applications.

- Nitrile Rubber: Offers excellent oil resistance, making it ideal for industrial applications.

Applications in Various Industries

Extrusion manufacturing plays a pivotal role in various industries, owing to its flexibility, cost-effectiveness, and ability to produce complex shapes. Below are some of the key industries that significantly benefit from extrusion manufacturing.

Automotive

The automotive industry heavily relies on extrusion manufacturing for various parts and components.

- Chassis Components: Aluminum extrusions often form the structural components of vehicle chassis.

- Interior Features: Plastic extrusions are common in dashboards, door panels, and other interior components.

- Seals and Gaskets: Rubber extrusions are frequently used for weather stripping and seals.

Relevant Information: Automotive Industry Wikipedia

Construction

Construction is another industry where extrusion manufacturing has found extensive use.

- Pipes and Tubing: PVC and metal pipes are commonly produced through extrusion.

- Window Frames: Aluminum and plastic extrusions are popular choices for window frames.

- Structural Beams: Steel and aluminum extrusions offer high strength-to-weight ratios ideal for construction.

Relevant Information: Construction Wikipedia

Aerospace

In the aerospace industry, weight and strength are critical factors, making extrusion manufacturing a natural fit.

- Fuselage Components: Aluminum extrusions are often used in the fuselage for weight reduction.

- Engine Parts: Titanium extrusions are common due to their high strength and low weight.

- Cabling Systems: Copper and other metals are extruded for electrical systems.

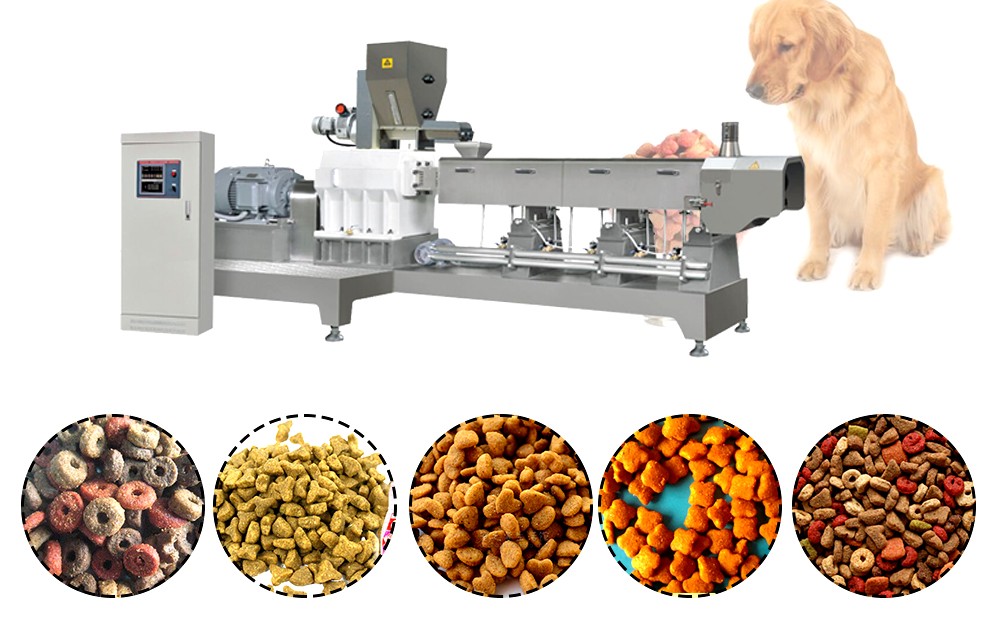

Food Processing

Although less obvious, food processing is another area where extrusion manufacturing plays a role.

- Snack Foods: Cornmeal and other grains are often extruded to create snacks like puffed rice.

- Pasta: Different shapes of pasta are produced using extrusion.

- Pet Food: Extrusion processes are used to shape and cook pet food.

Technological Innovations

Extrusion manufacturing is not static; it continues to evolve thanks to various technological advancements. Innovations in automation, software, and material science have all contributed to making the process more efficient, versatile, and environmentally friendly.

Automation in Extrusion

Automation has significantly impacted the efficiency and precision of extrusion manufacturing.

- Robotic Handling: Robots now assist in moving extruded products, reducing labor costs and improving accuracy.

- Quality Control: Automated sensors and cameras monitor the quality of extruded products in real-time.

- Batch Processing: Automation enables the running of large-scale batches with minimal human intervention.

Software Advancements

Software innovations have been instrumental in elevating the capabilities of extrusion manufacturing.

- Simulation Software: Advanced software allows manufacturers to simulate extrusion processes before actual production, reducing waste and improving efficiency.

- Data Analytics: Software tools analyze performance metrics to optimize the extrusion process.

- Inventory Management: Advanced software aids in real-time inventory tracking, which is crucial for large-scale operations.

Relevant Information: Software in Manufacturing Wikipedia

Material Science Innovations

Advancements in material science have opened up new possibilities for extrusion manufacturing.

- High-Performance Polymers: New types of plastics provide enhanced properties like higher heat resistance or greater strength.

- Recycled Materials: Innovations in material science have made it easier to use recycled materials in the extrusion process.

- Composite Materials: The development of composites allows for products with enhanced properties like increased strength or reduced weight.

Environmental Benefits

Innovations in technology and material science make it one of the more sustainable options available in the manufacturing sector. From reducing waste to optimizing energy use and promoting sustainable materials, extrusion manufacturing offers several eco-friendly advantages.

Waste Reduction

Waste minimization is one of the more immediate environmental benefits of extrusion manufacturing.

- Continuous Process: The continuous nature of extrusion manufacturing minimizes material scrap, thereby reducing waste.

- Recycling: Many extrusion plants integrate recycling facilities to reprocess scrap material.

- Precision: Advanced control systems minimize errors, which further reduces waste.

Energy Efficiency

Energy consumption is another area where extrusion manufacturing shines in terms of sustainability.

- Lower Temperatures: Some materials, like certain plastics, require lower temperatures for extrusion, thus consuming less energy.

- Optimized Machinery: Modern extrusion machines are designed for optimal energy usage.

- Process Improvements: Ongoing research and development in machinery and process design aim for greater energy efficiency.

Relevant Information: Energy Efficiency Wikipedia

Sustainable Materials

The use of sustainable materials further amplifies the environmental benefits of extrusion manufacturing.

- Bioplastics: The use of bioplastics is becoming more common, providing an eco-friendly alternative to traditional plastics.

- Recycled Metal: Extrusion plants increasingly use recycled metal to lower the carbon footprint.

- Green Composites: The development of eco-friendly composite materials is on the rise, combining natural fibers with recyclable resins.

Quality and Consistency

One of the standout features of extrusion manufacturing is its ability to produce high-quality and consistent products. Through precision engineering, scalability, and rigorous quality control measures, extrusion manufacturing assures products that meet industry standards and consumer expectations.

Precision

Precision in extrusion manufacturing is crucial for industries where even slight deviations can result in product failure.

- Tolerance Levels: Advanced machinery ensures that products meet specific tolerance levels, reducing the likelihood of defects.

- Computer-Aided Design (CAD): The use of CAD software allows for extremely precise design specifications.

- Tooling: Custom tooling allows for high levels of precision in the extrusion process.

Relevant Information: Precision Engineering Wikipedia

Scalability

Scalability in extrusion manufacturing refers to the capability to adapt production volume without sacrificing quality.

- Batch Processing: Automation enables high-volume batch processing, maintaining consistency across large product runs.

- Modular Equipment: Modern extrusion systems often feature modular designs that can be easily scaled up or down.

- Supply Chain Management: Advanced software helps in scaling production in line with supply chain demands.

Quality Control Measures

Quality control measures are integral to maintaining high standards in extrusion manufacturing.

- Quality Checks: Automated systems continually monitor production, allowing for immediate adjustments.

- Material Testing: Before extrusion, materials often undergo rigorous testing to ensure they meet quality standards.

- Post-Production Audits: Random sampling and inspection occur after production to verify quality and consistency.