Injection molding was invented by John Wesley Hyatt and his brother Isaiah in the late 19th century, revolutionizing plastic production.

The Origin of Injection Molding

Early Concepts and Inventions

The inception of injection molding traces back to the 19th century. It began as an experiment to create new products:

Initial Attempts: Early attempts focused on developing methods to simplify the production of plastic goods.

Material Use: Early injection molding used materials like celluloid and gutta-percha.

Process Evolution: The process evolved from a simple plunger mechanism to more complex systems for injecting molten material into molds.

These initial endeavors laid the groundwork for modern injection molding techniques.

John Wesley Hyatt’s Contributions

John Wesley Hyatt, a key figure in the history of injection molding, made significant contributions:

Celluloid Innovation: In 1868, Hyatt developed a way to process celluloid, making it usable for injection molding.

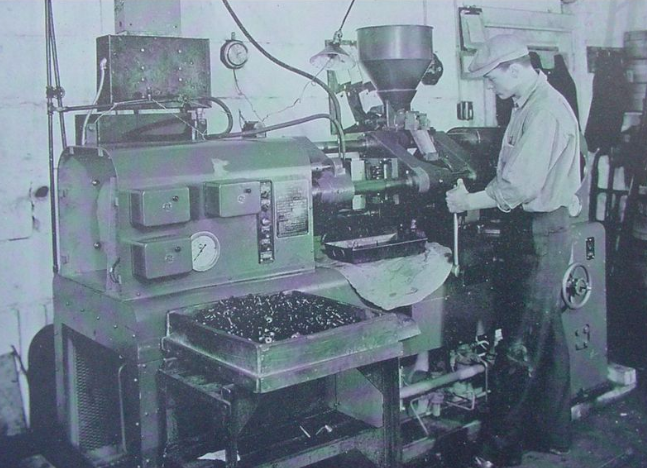

First Injection Molding Machine: Around 1872, Hyatt and his brother invented and patented the first injection molding machine.

Impact on Industry: Hyatt’s machine used a plunger to inject celluloid into a mold, a concept foundational to modern injection molding.

Significance of Hyatt’s Work:

Manufacturing Efficiency: Hyatt’s machine significantly improved the efficiency of producing plastic products.

Paving the Way for Plastics: His work opened doors for the widespread use of plastics in manufacturing.

For more detailed historical context, see John Wesley Hyatt on Wikipedia.

Evolution of Injection Molding Technology

Advancements in the Early 20th Century

The early 20th century marked significant advancements in injection molding technology, enhancing its efficiency and usability.

Key Developments:

| Year | Advancement | Impact |

|---|---|---|

| Early 1900s | Introduction of Bakelite | First synthetic plastic, suitable for injection molding, revolutionized the industry. |

| 1920s | Development of Screw Injection Machines | Improved the homogeneity of the molten material, enhancing product quality. |

| 1930s | Use of Newer Materials | Introduction of materials like polystyrene and polyvinyl chloride expanded applications. |

These innovations set the stage for more sophisticated injection molding techniques and materials.

Post-World War II Developments

The period following World War II witnessed further advancements in injection molding technology, driven by high demand and technological innovation.

Technological Progress:

| Decade | Development | Impact |

|---|---|---|

| 1940s-1950s | Automation in Injection Molding | Machines became more automated, increasing production speeds and reducing labor costs. |

| 1960s | Introduction of Computer-Controlled Systems | Enhanced precision and control in the injection molding process. |

| 1970s | Adoption of More Diverse Plastics | Broadened the range of products that could be made using injection molding. |

Post-War Impact:

Increased Production Capacity: Automation and improved machine designs allowed for higher volume production.

Enhanced Precision and Flexibility: Computer-controlled systems revolutionized the manufacturing capabilities of injection molding.

For a detailed exploration of this technological evolution, visit Injection Molding on Wikipedia.

Key Innovations and Patent Milestones

First Injection Molding Machine

The journey of injection molding technology began with the invention of the first machine, marking a significant milestone in manufacturing history.

Inventors: John Wesley Hyatt and his brother Isaiah patented the first injection molding machine in the 1870s.

Design Features: This machine used a basic plunger to inject material into a mold, a fundamental concept still recognizable in modern machines.

Impact on Manufacturing: It allowed for the mass production of items, previously made by hand, revolutionizing the manufacturing of combs, buttons, and other items.

Breakthroughs in Machine Design:

Increased Efficiency: Over time, machines evolved with capabilities to produce more complex parts at higher speeds and with greater precision.

Adoption of Hydraulics and Electrics: The integration of hydraulic and electric systems in the 20th century vastly improved control and efficiency.

Notable Patents in Injection Molding History

Injection molding’s evolution has been marked by several key patents that have shaped the industry.

Screw Injection Molding (Patented in 1952): Revolutionized the method of material preparation and injection, improving consistency and quality of the molded parts.

Gas-Assisted Injection Molding (1979): Introduced a new way to mold large, complex parts with hollow sections, reducing material use and part weight.

Co-Injection Molding: A later development that allows for the molding of parts with multiple materials, enhancing product functionality and aesthetic appeal.

Patent Impact:

Technological Diversity: Each patent introduced new capabilities, from material handling to creating complex part geometries.

Enhanced Product Quality: Innovations led to improvements in surface finish, strength, and precision of injection molded products.

For more on these innovations, explore Injection Molding Patents on Wikipedia.

Influential Figures in Injection Molding Development

Pioneers in Injection Molding Technology

The evolution of injection molding technology owes much to the contributions of various pioneers who laid the foundational concepts and made groundbreaking advancements.

John Wesley Hyatt: Revolutionized the plastics industry with the invention of the first injection molding machine in the 1870s.

James Watson Hendry: Introduced the screw injection molding machine in 1952, enhancing material quality and allowing for precise control over the injection process.

Dr. Peter Schlumbohm: Innovated with the development of thermosetting plastics in the 1930s, expanding the range of materials used in injection molding.

Impact of Their Innovations:

Hyatt: His machine initiated the transition from manual labor to mechanized production in the plastics industry.

Hendry: His screw design is still a fundamental component in modern injection molding machines, enabling the efficient production of complex parts.

Schlumbohm: His work with thermosetting plastics broadened the applications of injection molding, especially in high-temperature environments.

Contributions of Industrialists and Engineers

The progress in injection molding technology has also been driven by the contributions of various industrialists and engineers.

Leo Hendrik Baekeland: Invented Bakelite in 1907, the first true synthetic plastic, which was subsequently used in injection molding.

William Lester: His advancements in the 1940s and 1950s included refining hydraulic presses for injection molding, greatly improving the process’s efficiency.

Heinz List: Developed significant improvements in the injection molding of rubber in the mid-20th century.

Their Lasting Legacy:

Baekeland: Bakelite opened new possibilities for durable and heat-resistant plastic products.

Lester: His hydraulic press improvements allowed for greater control and faster production cycles in injection molding.

List: His innovations in rubber injection molding expanded the technology’s reach into new materials and applications.

For more information on these influential figures, visit Injection Molding History on Wikipedia.