Peak pressure in injection molding is the highest pressure applied during material injection into the mold.

Understanding Peak Pressure in Injection Molding

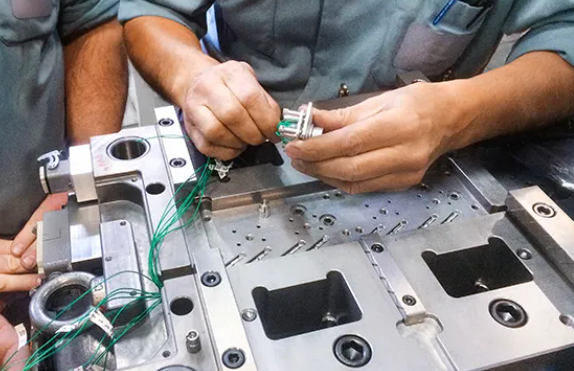

Definition and Significance Peak pressure, in the context of injection molding, refers to the highest level of pressure applied during the injection phase where molten plastic is injected into the mold cavity. This pressure is crucial for ensuring the molten material fills the entire cavity, reaching all intricate geometries, and for achieving optimal material density. High-quality molding depends significantly on accurate pressure management. Properly set peak pressure ensures complete cavity filling, minimal material waste, and consistent product quality.

Factors Influencing Peak Pressure Several factors play a pivotal role in determining the peak pressure in injection molding. These include:

Mold Design

Mold design, encompassing the size and complexity of the mold, significantly impacts the required peak pressure. A more intricate mold with fine details requires higher pressure to fill completely. Conversely, simpler designs with larger cavities often need lower pressure.

Material Properties

The type of plastic being molded is a critical factor. Different materials have varying flow characteristics. For instance, materials like polyethylene flow easily, requiring lower pressure, whereas more viscous materials like polycarbonate demand higher pressure for effective molding.

Machine Specifications

The specifications of the injection molding machine, particularly its maximum injectable pressure capacity, dictate the achievable peak pressure. Machines with higher power ratings can generate greater pressure, accommodating a broader range of materials and mold designs.

Process Parameters

Other process parameters, such as injection speed and temperature, influence peak pressure. Higher temperatures can reduce material viscosity, potentially allowing for lower injection pressures. Conversely, faster injection speeds might require increased pressure to maintain quality.

Measurement and Monitoring of Peak Pressure

Techniques for Measuring Peak Pressure Measuring peak pressure accurately is essential in injection molding to ensure high-quality production. Manufacturers employ various techniques to achieve this:

Direct Pressure Measurement

Direct pressure measurement is the most straightforward approach. It involves using sensors placed inside the mold or within the injection molding machine. These sensors, typically pressure transducers, provide real-time data on the pressure being exerted during the injection process. The accuracy of these sensors is critical for ensuring precise control over the molding process.

Indirect Pressure Measurement

Indirect measurement techniques might involve analyzing the machine’s hydraulic pressure to estimate the pressure within the mold. Although less direct than using in-mold sensors, this method can be effective, especially in machines where direct measurement is not feasible due to design constraints.

Importance of Monitoring Pressure in the Molding Process Monitoring peak pressure during the injection molding process is vital for several reasons:

Ensuring Product Consistency

Consistent pressure application guarantees that each product has the same dimensions, weight, and material properties. This uniformity is crucial, especially in large-scale production where even minor deviations can lead to significant quality issues.

Reducing Material Waste

Precise pressure control helps in minimizing material wastage. Over-pressurizing can lead to excessive material being injected into the mold, resulting in wastage. Conversely, under-pressurizing can lead to incomplete filling of the mold, producing defective products.

Enhancing Machine Lifespan

Proper pressure management also contributes to the longevity of the injection molding machine. Excessive or uneven pressure can strain the machine, leading to faster wear and tear. By maintaining optimal pressure levels, the machine’s lifespan can be extended, which is a cost-effective strategy for manufacturers.

Improving Safety

High-pressure environments can pose safety risks. Effective monitoring and control of the pressure ensure a safer working environment, reducing the likelihood of accidents due to equipment failure or material spillage.

Impact of Peak Pressure on Injection Molding Quality

Peak pressure in injection molding significantly influences the quality of the final product. This section explores the relationship between pressure and mold quality and identifies common defects arising from improper pressure management.

Relationship Between Pressure and Mold Quality

Peak pressure needs to be carefully calibrated to ensure high-quality molding. The pressure applied during the injection process determines how well the material fills the mold and conforms to its shape and specifications.

- Complete Filling of the Mold: Adequate pressure ensures that the molten plastic fills the entire mold, reaching all the corners and replicating the intricate details.

- Reduction in Material Stress: Proper pressure application reduces internal stresses within the molded part. This results in a stronger, more durable product.

- Aesthetic Quality: Consistent pressure contributes to a smooth surface finish and helps avoid defects like sink marks or surface blemishes.

Common Defects Associated with Improper Pressure

Several defects can occur due to incorrect pressure settings during the injection molding process:

Short Shots

- Description: Incomplete filling of the mold, resulting in partial or incomplete parts.

- Cause: Often due to insufficient pressure to push the material into all areas of the mold.

- Impact: Leads to material wastage and increases the rate of defective production.

Flash

- Description: Excess plastic that seeps out of the mold cavity, forming thin protrusions on the edges of the part.

- Cause: Excessive pressure forcing material beyond the confines of the mold cavity.

- Impact: Requires additional labor to remove the excess material, impacting both cost and production time.

Burn Marks

- Description: Discolored or burnt areas on the final product.

- Cause: Too high pressure can increase the temperature of the material excessively.

- Impact: Affects the aesthetic and structural integrity of the part, leading to potential rejection of the product.

Warping

- Description: Deformation of the part as it cools and solidifies.

- Cause: Uneven pressure during injection and cooling can cause parts to cool at different rates, leading to warping.

- Impact: Results in a product that does not meet the required specifications and dimensions.

Optimizing Peak Pressure in Injection Molding

Optimizing peak pressure in injection molding is key to improving the quality, efficiency, and cost-effectiveness of the production process. This section outlines strategies for pressure optimization and highlights some case studies demonstrating effective pressure management.

Strategies for Pressure Optimization

Effective pressure optimization involves a combination of technological advancements, process adjustments, and consistent monitoring. Here are some strategies:

- Real-Time Monitoring and Control: Implement advanced monitoring systems to track and adjust pressure in real time. This approach helps in maintaining consistent quality throughout the production run.

- Material and Process Compatibility: Choose materials that are compatible with the mold design and machine capabilities. Matching material properties with the right pressure settings can reduce defects and improve product quality.

- Machine Calibration and Maintenance: Regular calibration and maintenance of injection molding machines ensure that they operate within the optimal pressure ranges. This practice can extend machine lifespan and reduce downtime.

Case Studies: Effective Pressure Management

Several manufacturers have successfully implemented pressure optimization strategies, leading to significant improvements in their production processes:

Case Study 1: Automotive Parts Manufacturer

- Challenge: The company faced issues with inconsistent part quality and high reject rates due to variable pressure settings.

- Solution: They implemented a closed-loop control system for real-time pressure monitoring and adjustment.

- Outcome: The reject rate decreased by 30%, and the overall production efficiency increased, leading to cost savings and higher customer satisfaction.

Case Study 2: Medical Device Producer

- Challenge: The precision requirements for medical devices meant that even minor pressure deviations could render parts unusable.

- Solution: The company invested in advanced sensors and machine learning algorithms to predict and adjust pressure settings preemptively.

- Outcome: This resulted in a 25% improvement in production consistency and a significant reduction in material wastage.

Technological Advances in Pressure Control

The field of injection molding has witnessed significant technological advancements, particularly in pressure control. These innovations not only enhance product quality but also improve efficiency and reduce costs.

Innovations in Pressure Measurement and Control

Advancements in pressure control technology have been instrumental in refining injection molding processes:

- Smart Sensors and IoT Integration: The integration of Internet of Things (IoT) technology with smart sensors has revolutionized pressure monitoring. These sensors provide real-time data, enabling immediate adjustments for optimal pressure settings.

- Machine Learning and AI: Artificial intelligence (AI) and machine learning algorithms are being used to predict optimal pressure settings based on historical data and current operating conditions. This predictive approach can significantly reduce defects and improve efficiency.

- Advanced Hydraulic Systems: Modern hydraulic systems in injection molding machines offer more precise control of pressure. These systems are designed to adjust the pressure dynamically, based on the mold’s requirements.

Future Trends in Pressure Management in Injection Molding

The future of pressure management in injection molding looks promising, with several emerging trends:

- Increased Automation: Automation in pressure control is expected to become more prevalent. Automated systems can make adjustments in real-time, reducing the need for manual intervention and enhancing production consistency.

- Eco-Friendly Solutions: There is a growing trend towards more energy-efficient and sustainable practices. Future pressure control technologies are likely to focus on reducing power consumption and minimizing environmental impact.

- Customization and Flexibility: As the demand for customized products grows, pressure control systems will need to become more adaptable. This means systems capable of adjusting to different materials and mold designs quickly and efficiently.