The most common type of extrusion is “direct extrusion,” where a billet is pushed through a die to create a continuous shape or profile.

Overview of Extrusion Process

Definition of Extrusion

Extrusion stands as a manufacturing process where a manufacturer pushes or draws material through a die to create fixed cross-sectional profile products. This technique finds extensive use in producing diverse items like simple tubing, complex window frames, and wire insulation.

Basic Principles of Extrusion

At the heart of extrusion is the principle of feeding a selected material, such as plastic or metal, into an extruder. Within this machine, a rotating screw actively forces the material through a die, giving it the desired shape. The material then solidifies, retaining this specific profile.

Energy Efficiency: Generally, extrusion processes consume moderate amounts of energy, varying with the material type and profile complexity.

Production Speed: Known for high production rates, extrusion is perfect for large-scale manufacturing needs.

Material Versatility: Extrusion accommodates a broad spectrum of materials, ranging from various metals to polymers, each bringing its own set of properties and cost implications.

Precision and Quality: This process ensures consistent cross-sectional shapes with high precision, crucial for many applications.

Cost Factors: Although the initial setup for extrusion can be expensive due to the need for specialized dies and equipment, the operational costs are relatively lower, especially for high-volume production.

In conclusion, extrusion emerges as a versatile and efficient manufacturing process, ideal for various materials and applications. Its capacity to consistently produce high-quality products swiftly and at a comparatively low cost makes it a preferred method across multiple industries. Discover more about extrusion and its applications on Extrusion’s Wikipedia page.

Common Extrusion Materials

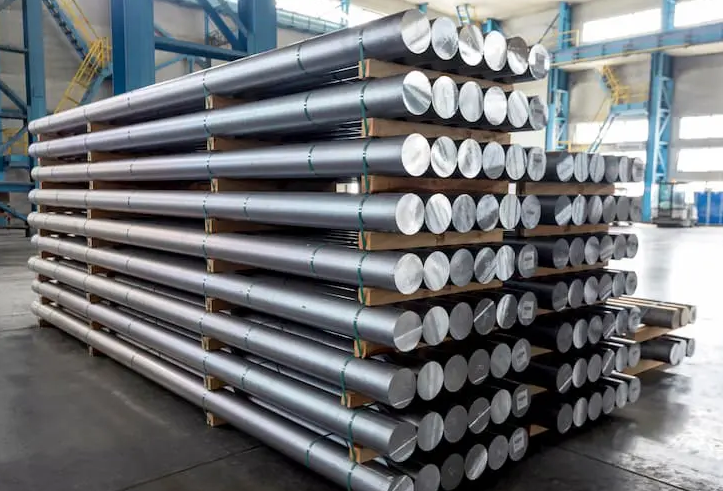

Metals Used in Extrusion

Extrusion frequently employs metals for their strength and durability. Aluminum ranks as the most popular due to its lightweight nature and corrosion resistance. Its cost varies, generally around $0.85 to $1.30 per pound, making it an economical choice for many applications.

Aluminum: Ideal for its low density, ease of machining, and excellent thermal conductivity.

Steel: Known for higher strength, steel is suitable for more demanding applications, albeit at a higher cost.

Copper: Offers superior electrical conductivity, commonly used in electrical components.

Plastics and Polymers for Extrusion

Plastics and polymers are equally essential in extrusion, prized for their versatility and cost-effectiveness. Polyethylene, for instance, is widely used due to its low cost, approximately $0.75 to $2 per pound, and flexibility in applications ranging from packaging to automotive parts.

Polyethylene (PE): Offers versatility and cost-effectiveness, suitable for a wide range of products.

Polyvinyl Chloride (PVC): Known for its durability and resistance to environmental factors, ideal for outdoor applications.

Polystyrene (PS): Common in consumer products for its ease of molding and aesthetic qualities.

Each material brings unique benefits and challenges, influencing its suitability for specific applications. For instance, while metals offer higher strength, they might incur higher costs. In contrast, plastics provide cost savings but may not match the mechanical strength of metals. Manufacturers must carefully consider these factors when choosing materials for their extrusion projects. For more detailed insights, explore Materials in Extrusion on Wikipedia.

Applications of Common Extrusion Types

Industrial Applications

In the industrial sector, extrusion plays a critical role. Manufacturers widely use it for creating complex cross-sectional profiles like pipes, tubes, and structural components. The strength and durability of extruded parts are essential for industrial use, especially in construction and automotive industries.

Construction Materials: Extruded aluminum and steel are popular for framing, railing, and scaffolding due to their strength and resistance to corrosion.

Automotive Parts: Components like frames, rails, and trim benefit from the lightweight yet strong nature of extruded metals, contributing to overall vehicle efficiency.

Cost Efficiency: While the initial investment in extrusion machinery can be high, the long-term savings in material costs and production efficiency make it a viable choice for industrial applications.

Consumer Products

In the realm of consumer products, extrusion finds its way into everyday items. Plastics and polymers, due to their versatility and cost-effectiveness, are the go-to materials for these applications.

Household Goods: Items like garden hoses, window frames, and plastic sheets are commonly produced through extrusion, offering durability and design flexibility.

Packaging Materials: Extruded polymers like polyethylene are extensively used in packaging for their lightweight nature and adaptability.

Affordability: Plastic extrusion is notably cost-effective, making it suitable for mass production of consumer goods.

Each application area of extrusion benefits from the process’s ability to produce consistent, high-quality products. Industrial applications often prioritize strength and durability, while consumer products focus on cost-effectiveness and versatility. For a more in-depth understanding, one can explore Extrusion Applications on Wikipedia.

Comparative Analysis of Extrusion Types

A comprehensive comparison of different extrusion types is essential to understand their efficiency, costs, quality, and material suitability. This analysis utilizes a table format to provide a clear and detailed comparison.

| Feature | Hot Extrusion | Cold Extrusion | Micro-Extrusion |

|---|---|---|---|

| Efficiency | High efficiency for metals | More efficient for plastics | Best for small, precise components |

| Cost | Moderate to high due to energy consumption | Lower operational costs | Higher due to specialized equipment |

| Material Suitability | Best for metals like aluminum and steel | Ideal for plastics and softer metals | Suitable for high-precision materials |

| Quality | Excellent surface finish | Superior strength and surface finish | Exceptional precision and detail |

| Production Speed | Faster for larger quantities | Comparable, depends on material | Slower, focused on precision |

| Advantages | Great for large-scale production | Less energy consumption, better for environment | Perfect for intricate, small parts |

| Challenges | Higher energy consumption | Limited to softer materials | Requires advanced technology, higher costs |

Hot Extrusion is highly efficient for processing metals and suitable for large-scale production, though it incurs higher energy costs. Cold Extrusion is more cost-effective and environmentally friendly, though it’s limited to softer materials. Micro-Extrusion excels in precision but requires more advanced technology, leading to higher costs.

This table provides a clear understanding of how each extrusion type performs in various aspects, helping manufacturers and engineers make informed decisions based on their specific requirements. For additional information, one can explore Extrusion Types on Wikipedia.