The melting mechanism of extrusion involves shear-induced heating and conductive heat transfer, facilitating material transformation from solid to molten state within the extruder.

Basic Principles of Extrusion

Extrusion is a widely used manufacturing process wherein a material, often in the form of a billet, is forced to flow through a specific shaped opening to produce an elongated product with a continuous profile. The extrusion process is utilized in a variety of industries, from food to plastics to metals. As such, understanding its basic principles is pivotal for professionals in these fields.

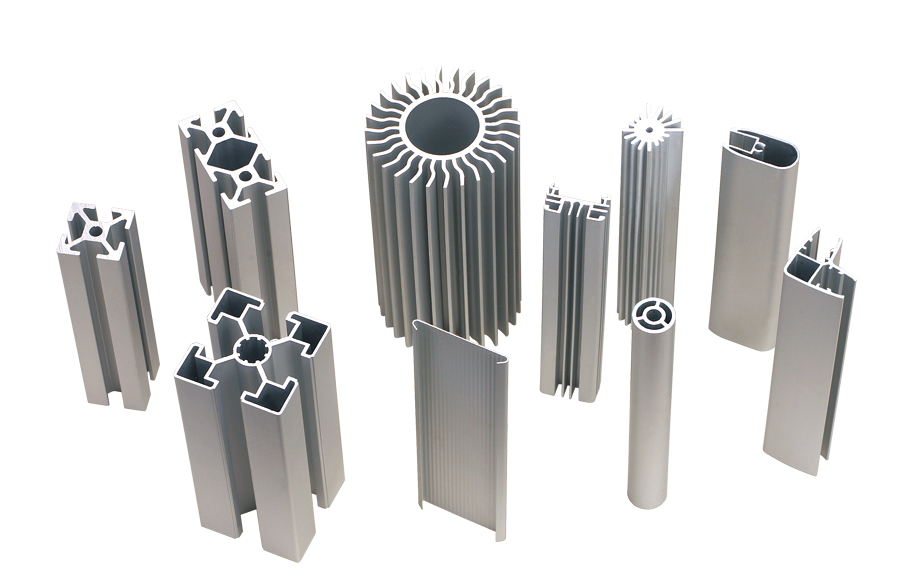

Definition and Types of Extrusion

Extrusion can be defined as the process of shaping a material by forcing it through a designed opening in a die. Based on various factors, including the method of operation and the state of the material, extrusion can be categorized into different types:

- Cold Extrusion: This type of extrusion is carried out at room temperature or slightly above it. It’s often used for metals like tin, lead, and aluminum. Cold extrusion offers advantages such as good surface finish and enhanced mechanical properties. Here’s more on cold extrusion from Wikipedia.

- Hot Extrusion: As the name suggests, in hot extrusion, the material is heated above its recrystallization temperature before being extruded. This method is preferred for metals that don’t easily deform at room temperature, like steel and titanium.

- Blown Film Extrusion: This method is mainly used for making plastic films.

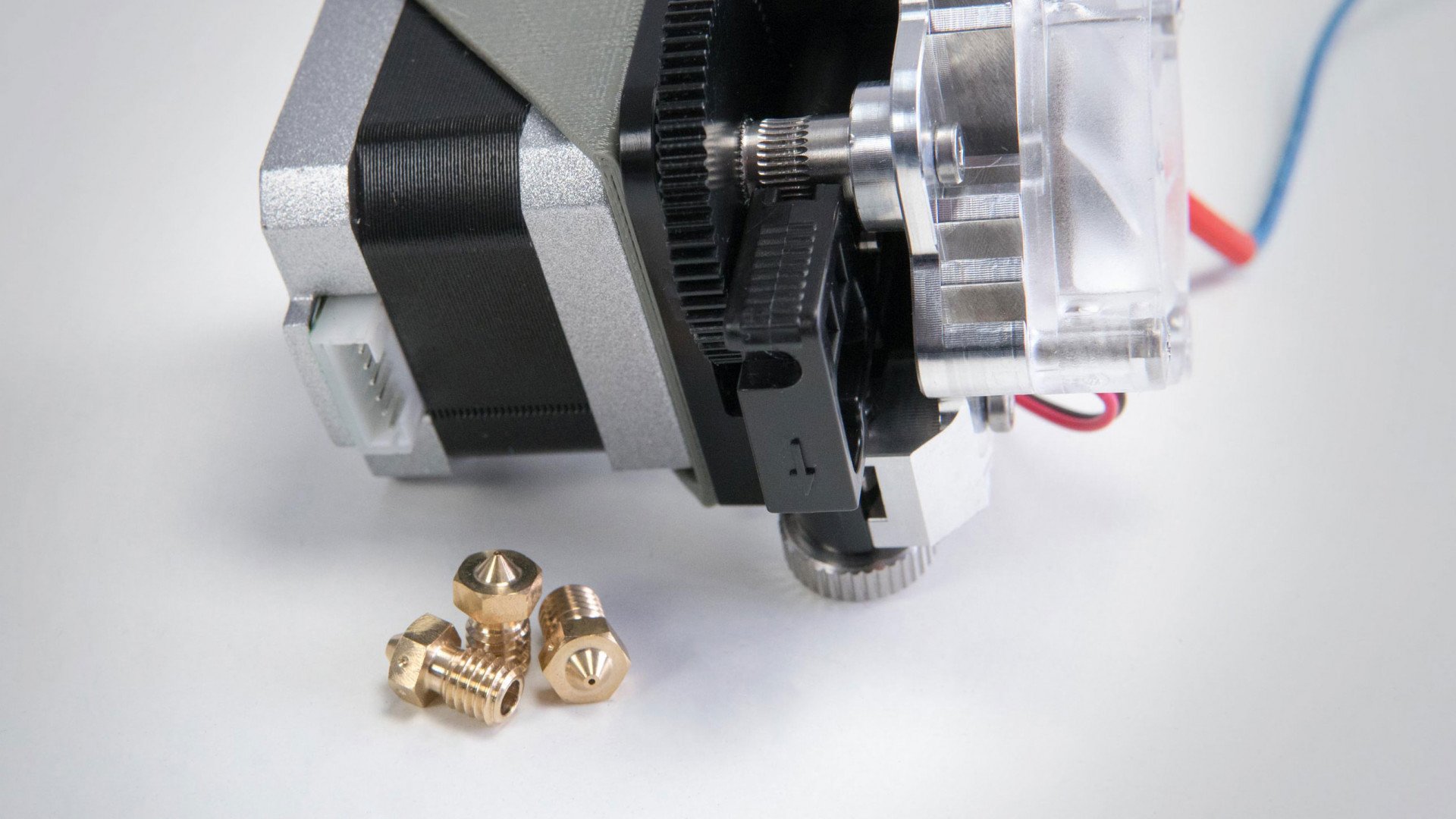

Components of an Extruder

An extruder is primarily composed of several key components, each playing a specific role in the extrusion process:

- Hopper: This is where the raw material, often in the form of granules or powder, is loaded. It serves as the entry point for the material into the extruder.

- Barrel: Typically a long, cylindrical component where the actual extrusion process takes place.

- Screw: Located inside the barrel, it’s responsible for pushing, mixing, and melting the material. Its design and geometry can vary based on the specific application.

- Die: The shaped opening at the extruder’s end where the molten material is pushed through to acquire the desired shape.

- Heating/Cooling Units: These are essential for controlling the temperature during the extrusion process. Especially crucial in processes like hot extrusion.

Mechanisms Leading to Melting in Extrusion

Extrusion, a popular manufacturing process, requires the conversion of solid material into a molten or semi-molten state to enable its flow through specific shaped dies. The melting in the extrusion process isn’t as simple as just applying heat. It results from a combination of mechanical and thermal energies, leading to a number of distinct mechanisms. This section delves deep into these melting mechanisms, providing clarity on each aspect.

Shear-Induced Melting

When materials, especially polymers, are subjected to shear forces inside the extruder, they tend to generate heat. This is primarily because of the internal molecular friction within the material. The screw inside the extruder plays a crucial role in this mechanism. As the screw rotates, it imparts shear forces to the material, leading to heat generation. Materials with higher molecular weight or long-chain polymers often exhibit more pronounced shear-induced melting. A deeper dive into shear-induced phenomena is available on Wikipedia.

Conductive Heat Transfer

Conductive heat transfer is a mechanism where heat moves through a material without the material itself moving. In the context of an extruder, the barrel, which often has heating elements, transfers heat directly to the material through conduction. Metals, for instance, have high thermal conductivity, which means they can transfer heat quickly. Plastics, depending on their type, might have lower thermal conductivity, requiring external heaters along the barrel to aid the process.

Convection-Driven Melting

Convection involves the movement of heat due to the motion of the heated material itself. Inside an extruder, as the molten parts of the material start flowing, they carry the heat with them, leading to a more uniform melting. This mechanism is essential to ensure a consistent temperature profile inside the extruder, ensuring that the material has a uniform consistency as it reaches the die.

Dissipative Heating Due to Viscous Flow

Viscous dissipation refers to the phenomenon where the flow of viscous materials leads to heat generation. When materials with high viscosity, like certain polymers, are forced to flow inside the extruder, there’s resistance to their movement. This resistance, or internal friction, causes the material to heat up. Over time, as the material continues to flow and experience this friction, the heat generation can become significant, contributing to the overall melting of the material.

Factors Affecting the Melting Mechanism

Understanding the melting mechanism in extrusion is essential, but equally crucial is recognizing the variables that can influence this mechanism. By adjusting these factors, one can control the rate and consistency of melting, ensuring optimal product quality. Below, we’ll explore the key elements that play pivotal roles in the melting process during extrusion.

Screw Design and Geometry

The screw is the heart of the extrusion process. Its design determines how the material moves, mixes, and melts:

- Flight Depth: A deeper flight can carry more material, influencing the residence time and shear applied to the material. Conversely, a shallower flight may lead to faster melting due to increased shear.

- Pitch: A screw with a tighter pitch might compress the material more, leading to increased internal friction and heating.

- Length-to-Diameter Ratio (L/D): A longer screw (higher L/D ratio) can provide more residence time for the material, ensuring complete melting.

For a detailed understanding of screw design intricacies, one can explore this Wikipedia link on extruder screws.

Material Properties and Behavior

Different materials react differently under the same conditions:

- Thermal Conductivity: Materials with high thermal conductivity, like metals, transfer heat quickly, affecting the rate of melting.

- Viscosity: High-viscosity materials can produce more heat due to viscous dissipation when they flow.

- Molecular Structure: Polymers with long molecular chains or higher molecular weights may require more energy to melt and can exhibit pronounced shear-induced melting.

- Fillers and Additives: The presence of fillers or additives can change a material’s melting behavior. Some fillers might act as insulators, while others could enhance thermal conductivity.

This Wikipedia article on materials science provides comprehensive insights into different material properties.

Processing Conditions (Temperature, Pressure)

External conditions during extrusion can significantly influence melting:

- Barrel Temperature: Setting the right barrel temperature is crucial. Too high, and the material might degrade; too low, and the material may not melt properly.

- Screw Speed: A faster screw speed can increase shear, leading to more shear-induced melting. However, it might also reduce the material’s residence time in the extruder.

- Back Pressure: By adjusting the die or using screens, one can control the pressure inside the extruder. Higher pressures can increase internal friction and, consequently, heat generation.

- Feed Rate: Overfeeding can cool down the extruder, while underfeeding might lead to excessive heating. Finding the right balance ensures consistent melting.

Importance of Melting Mechanism in Extrusion

The melting mechanism plays a central role in the extrusion process. While extrusion itself involves various steps and components, the manner in which the material melts directly influences the end product’s quality, the efficiency of the extruder, and more. Understanding the importance of the melting mechanism paves the way for better process control, quality assurance, and energy efficiency.

Role in Material Quality and Morphology

Melting has a direct impact on the microstructure and overall quality of the extruded product:

- Microstructure Evolution: The melting mechanism, along with the shear forces in the extruder, affects the orientation and arrangement of polymer chains or grains in metals. A controlled and uniform melting process ensures desirable properties like tensile strength, transparency, and ductility.

- Dispersal of Fillers and Additives: In compounds with additives or fillers, consistent melting ensures these components distribute uniformly throughout the material, imparting desired characteristics to the product.

- Avoidance of Defects: Uneven melting can lead to defects like voids, unmelted particles, or inconsistent coloring.

For a deep dive into material morphology, especially in polymers, you might want to explore this Wikipedia link.

Impacts on Product Consistency

Consistency is a hallmark of quality, and the melting mechanism is crucial in this respect:

- Dimensional Stability: Consistent melting ensures that the extruded product has uniform thickness and dimensions across its length.

- Reproducibility: A well-understood and controlled melting process allows for high repeatability, meaning products produced in different batches have similar quality and properties.

Influence on Extruder Efficiency and Energy Consumption

The melting mechanism isn’t just about the product; it also affects the machinery and operational costs:

- Energy Efficiency: Efficient melting processes require less external heating, leading to reduced energy consumption. This is particularly crucial in large-scale industrial setups where even small energy savings can translate to significant cost reductions.

- Wear and Tear: Inconsistent or improper melting can lead to increased resistance and pressure inside the extruder. Over time, this can wear out the screw, barrel, and other components, leading to frequent maintenance needs and reduced machine life.

- Throughput and Productivity: Proper melting ensures a smooth flow of material, allowing for faster extrusion rates without compromising on quality. This directly translates to increased production rates.

Advanced Techniques and Innovations

In the ever-evolving field of extrusion, there’s a continuous push for perfection. To achieve this, researchers and engineers relentlessly seek to understand, refine, and reimagine the melting process. Advanced techniques and groundbreaking innovations not only promise higher efficiency and product quality but also redefine the boundaries of what’s achievable with extrusion.

Computational Models for Melting Mechanisms

Computational models have emerged as powerful tools to simulate, understand, and predict the melting mechanisms in extrusion:

- Finite Element Analysis (FEA): FEA is a numerical method used to solve complex structural and thermal problems. By dividing the extruder into smaller elements, it predicts the temperature distribution, helping optimize heating zones for uniform melting.

- Computational Fluid Dynamics (CFD): CFD models the flow of molten material inside the extruder. It provides insights into areas of high shear, potential dead zones, and the overall flow pattern, ensuring efficient melting and optimal product quality.

- Predictive Maintenance Using Machine Learning: With the advent of AI and machine learning, predictive models can forecast when certain parts of the extruder, affected by the melting mechanism, might fail or need maintenance.

Innovations in Screw Design to Enhance Melting

The screw is at the heart of the extrusion process, and innovations in its design have a profound impact on melting:

- Barrier Screws: These have a secondary flight, creating a barrier, ensuring more uniform shear and faster melting.

- Mixing Elements: Some modern screws incorporate special mixing sections, enhancing the distributive and dispersive mixing, leading to uniform melting and additive distribution.

- Energy-efficient Screws: New designs focus on reducing energy consumption while achieving the same or better melting, making the process more sustainable.

Non-traditional Extrusion Methods and their Melting Dynamics

Beyond conventional extrusion techniques, some non-traditional methods are pushing the frontiers:

- Micro-extrusion: Designed for small-scale, high-precision applications, like in the medical field, micro-extrusion requires meticulous control over the melting process due to the minute dimensions involved.

- Co-extrusion: This involves extruding two or more materials simultaneously, creating multi-layered or composite products. The melting dynamics of each material need synchronization to ensure a seamless interface between the layers.

- Cryogenic Extrusion: Using extremely cold temperatures, this technique is often employed for materials that are difficult to extrude under standard conditions. The melting mechanism, in this case, is reversed, focusing on softening rather than fully melting the material.