Polycarbonate, recognized for its exceptional strength and toughness, is the hardest plastic commonly used in injection molding processes.

Understanding Plastic Hardness

Understanding plastic hardness is crucial in selecting the right material for injection molding. Hardness refers to the material’s resistance to permanent indentation, and it significantly affects the durability and wear resistance of the final product.

Defining Hardness in Plastics

- Resistance to Deformation: Hard plastics resist deformation under stress, making them ideal for high-impact applications.

- Shore Hardness Scale: Plastics are often measured on the Shore hardness scale, which assesses their resistance to indentation. The scale ranges from softer plastics (Shore A) to harder ones (Shore D).

- Material Density: Higher density often correlates with increased hardness, impacting the material’s strength and heat resistance.

Testing Methods for Plastic Hardness

- Shore Hardness Test: This test measures the depth of indentation under a standard force. It’s a quick and non-destructive method.

- Rockwell Hardness Test: This involves measuring the depth of penetration of an indenter under load, providing a numerical value indicative of the plastic’s hardness.

- Microhardness Test: Suitable for thin or small samples, this test provides precise measurements of surface hardness.

Plastics’ hardness affects power requirements in molding, with harder plastics typically requiring more power. The cost and efficiency of the process are also influenced, as harder plastics might need longer cycle times and higher processing temperatures. Key aspects include:

- Power Requirements: Hard plastics often require higher power for processing, impacting the overall energy consumption.

- Cost Implications: The use of hard plastics can lead to increased wear on molds, raising maintenance costs.

- Efficiency and Cycle Time: Harder materials may reduce the efficiency due to longer cooling and processing times.

- Quality and Durability: Hard plastics offer superior quality and durability, which can be critical in certain applications.

Types of Hard Plastics Used in Injection Molding

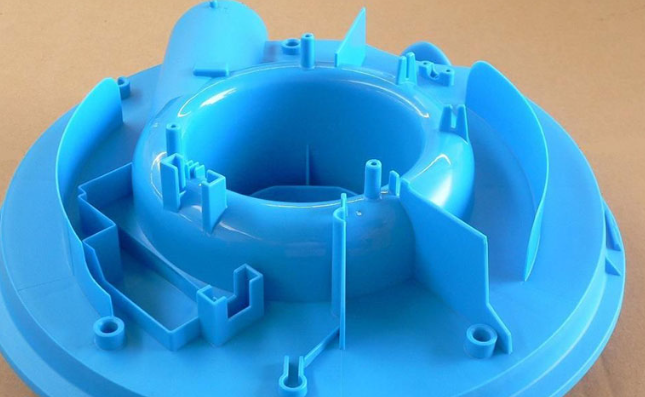

Hard plastics are pivotal in injection molding due to their robustness and versatility. These materials withstand high stress and have a broad range of applications, from automotive parts to consumer goods. The selection of hard plastics depends on factors like cost, durability, and specific performance requirements.

Polycarbonate (PC)

- Properties: Polycarbonate is known for its extraordinary strength and toughness. It’s transparent and can withstand extreme temperatures, making it ideal for various applications.

- Applications: Used in bulletproof glass, medical devices, and electronic components.

- Cost and Efficiency: While PC offers high durability, it comes at a higher cost compared to other plastics. Its processing requires careful temperature control to prevent degradation.

- Quality and Lifespan: Polycarbonate products have a long lifespan due to their high impact resistance and clarity.

Polyamide (Nylon)

- Properties: Nylon is renowned for its wear resistance and strength. It’s also lightweight and has good thermal properties.

- Applications: Commonly used in automotive parts, mechanical gears, and textile fibers.

- Cost Efficiency: Nylon offers a good balance between cost and performance. It is less expensive than PC but provides sufficient durability for many applications.

- Quality and Speed: Nylon parts are high in quality, with a relatively fast production speed due to its ease of processing.

Acrylonitrile Butadiene Styrene (ABS)

- Properties: ABS combines the strength and rigidity of acrylonitrile and styrene with the toughness of butadiene rubber. It’s a popular choice for its good overall performance.

- Applications: Widely used in the manufacturing of LEGO bricks, automotive parts, and electronic housings.

- Cost and Material Efficiency: ABS is cost-effective and easy to mold, which makes it a preferred choice for a wide range of applications.

- Quality and Durability: Offers excellent surface quality, impact resistance, and is easily paintable, which adds to its aesthetic appeal.

Challenges in Molding Hard Plastics

Molding hard plastics presents unique challenges that manufacturers must address to ensure high-quality, cost-effective, and efficient production. These challenges stem from the inherent properties of hard plastics, such as high melting points and sensitivity to processing conditions.

High-Temperature Requirements

- Increased Energy Consumption: Molding hard plastics often requires higher temperatures, leading to increased energy consumption. This can significantly impact the overall cost and efficiency of the production process.

- Risk of Degradation: High temperatures can cause some plastics to degrade, affecting the quality of the final product. Manufacturers need to carefully control the temperature to prevent this.

- Machinery Wear and Tear: Consistently high temperatures can accelerate wear and tear on the injection molding machines, potentially increasing maintenance costs and downtime.

Issues with Shrinkage and Warping

- Dimensional Inaccuracy: Shrinkage and warping are common issues when molding hard plastics. These can lead to dimensional inaccuracies in the final product, affecting its fit and function.

- Cooling Time and Costs: To minimize shrinkage and warping, longer cooling times are often required, which can slow down the overall production speed and increase costs.

- Material and Design Considerations: Manufacturers need to choose materials and design molds that can compensate for these effects. This might involve using plastics with lower shrinkage rates or designing molds with these factors in mind.

Case Studies: Injection Molding with Hard Plastics

Industrial Applications

- Automotive Sector: Hard plastics like ABS and Polycarbonate find extensive use in the automotive industry for parts like bumpers, dashboards, and interior panels. Their durability and resistance to impact and heat make them ideal for these applications.

- Medical Devices: High-impact polystyrene (HIPS) and Polyamide are often used in medical devices for their strength, sterilizability, and biocompatibility.

- Consumer Electronics: ABS, due to its aesthetic appeal and strength, is widely used in consumer electronics like phone cases and laptop housings.

Innovations and Breakthroughs

- Advanced Composite Materials: Recent innovations include the development of composite materials that combine hard plastics with fibers for enhanced strength and reduced weight.

- Eco-Friendly Materials: Breakthroughs in bio-based hard plastics are making waves, offering sustainability without compromising on strength and durability.

- Precision Molding Techniques: New molding techniques that allow for more precise control of temperature and pressure have led to higher quality and more complex parts.

Comparative Analysis of Hard Plastics

Performance Comparison

- Strength and Durability: Polycarbonate is often the strongest in terms of impact resistance, while ABS offers a good balance between strength, rigidity, and toughness.

- Heat Resistance: Polyamides excel in heat resistance, making them suitable for high-temperature applications.

- Flexibility and Malleability: While being hard, certain plastics like certain grades of Polyamide offer more flexibility, which is essential for specific applications.

Cost-Benefit Analysis

- Material Costs: Polycarbonate is generally more expensive than ABS and Polyamides, reflecting its superior properties.

- Processing Costs: ABS is easier and less costly to process than Polycarbonate, which requires higher temperatures and more energy.

- Long-term Benefits: While initial costs might be higher for some hard plastics, their durability and lifespan can offer long-term savings in replacements and maintenance.