The equation for injection molding involves resin flow, pressure, temperature, and cooling rate to create desired plastic parts.

Understanding the Injection Molding Equation

Fundamentals of Injection Molding Calculations

Injection molding calculations are essential for designing and running an efficient molding process. These calculations typically involve:

Mold Clamping Force: Determined by the projected area of the part and the pressure in the mold cavity.

Cooling Time: Essential for determining cycle time. Calculated based on mold and material specifics, the equation often used is: Cooling Time=constant×(Thickness2/Thermal Diffusivity).

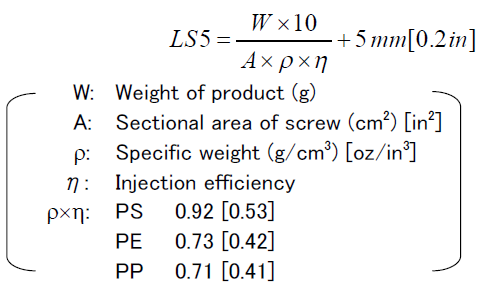

Shot Size: Calculated to ensure the right amount of material is used. It directly affects material costs and waste.

Understanding these fundamental calculations helps in optimizing the molding process, enhancing efficiency, and reducing costs.

Key Variables in the Injection Molding Equation

Several critical variables play a role in the injection molding equation:

Material Properties: Include melt flow index, thermal conductivity, and heat capacity. Each material will have unique values affecting the molding process.

Mold Dimensions: The size and complexity of the mold dictate the required clamping force and cooling time.

Machine Capabilities: Parameters like maximum injection pressure and clamping force capacity.

Optimizing these variables can lead to significant improvements in product quality and process efficiency.

For more insights into the science of injection molding, the Wikipedia page on Injection Molding is a valuable resource.

Equations for Injection Molding Process Parameters

Calculating Mold Clamping Force

Mold clamping force is critical in preventing mold flash. The equation used is:

Clamping Force = Projected Area of the Part × Injection Pressure

- Projected Area: Measured in square inches, this is the area of the part in the mold.

- Injection Pressure: Typically ranges between 10,000 to 20,000 psi for most materials.

Optimal clamping force ensures the mold stays closed during the injection process, directly influencing the quality and precision of the final product.

Determining Injection Pressure

The injection pressure must be calculated to ensure the molten plastic fills the entire mold cavity. The general equation is:

Injection Pressure = (Flow Length / Wall Thickness) × Material Viscosity × Flow Rate

- Flow Length and Wall Thickness: Key design aspects of the part.

- Material Viscosity: Depends on the plastic used.

- Flow Rate: Speed at which the plastic is injected, impacting the quality of the product.

Proper injection pressure is vital for achieving a defect-free injection molding process.

Estimating Cooling Time and Injection Time

Cooling time is a significant portion of the overall cycle time. The equation used is:

Cooling Time ≈ (Wall Thickness² / Thermal Diffusivity) × Constant

- Wall Thickness: Thicker parts require longer cooling times.

- Thermal Diffusivity: Depends on the material’s ability to conduct heat.

Injection Time can be estimated as:

Injection Time = Volume of the Part / Injection Speed

- Volume of the Part: Calculated based on part dimensions.

- Injection Speed: Typically in cubic inches per second, adjusted for part size and material.

Efficient cooling and injection times are essential for optimizing the production cycle and reducing costs.

For further details on these equations and their applications, refer to the Wikipedia page on Injection Molding.

Material Considerations in Injection Molding Equations

Impact of Material Properties on Molding Equations

Different materials significantly influence the injection molding process. Key properties include:

Melt Flow Index (MFI): Determines how easily the material flows in the mold. Higher MFI materials require lower injection pressures.

Thermal Conductivity: Affects cooling time. Materials with higher conductivity cool faster, reducing cycle time.

Strength and Flexibility: Influence mold design and part ejection strategy.

Understanding these properties allows for precise adjustments in molding equations, ensuring optimal product quality and process efficiency.

Adjusting Equations for Different Plastics

Each plastic type requires specific adjustments in the molding equations:

Polystyrene (PS): Often requires higher temperatures (around 180°C to 280°C) for effective molding.

Polyethylene (PE): Typically uses lower injection pressures due to its lower melt flow resistance.

ABS: Requires careful balance of temperature and pressure due to its higher strength and rigidity.

These adjustments ensure that each material is processed under optimal conditions, which is crucial for achieving desired product characteristics and minimizing defects.

For a deeper understanding of how different materials affect injection molding, explore the Wikipedia page on Injection Molding.

Practical Applications of Injection Molding Equations

Case Studies: Applying Equations in Real-World Scenarios

| Case Study | Material Used | Key Equation Adjustments | Outcome and Benefits |

|---|---|---|---|

| Automotive Part Molding | ABS | Increased injection pressure for complex geometry | High precision parts with reduced defects |

| Consumer Electronics Casing | Polycarbonate | Higher mold temperature for improved fluidity | Enhanced surface finish, meeting aesthetic requirements |

These case studies demonstrate how adjusting injection molding equations based on material properties leads to improved product quality and process efficiency.

Troubleshooting Common Issues with Equation-Based Solutions

| Common Issue | Potential Cause | Equation-Based Solution | Result |

|---|---|---|---|

| Short Shots | Insufficient material flow | Increase injection pressure | Complete cavity filling, eliminating short shots |

| Warping | Uneven cooling | Adjust cooling time based on thickness | Reduced warping, improved product quality |

By applying targeted solutions using molding equations, common injection molding issues can be effectively resolved, enhancing overall production quality.

For more comprehensive insights, the Wikipedia page on Injection Molding offers detailed information on the subject.