Polyethylene (PE) and Polypropylene (PP) are among the cheapest plastics used for injection molding.

Understanding Injection Molding Plastics

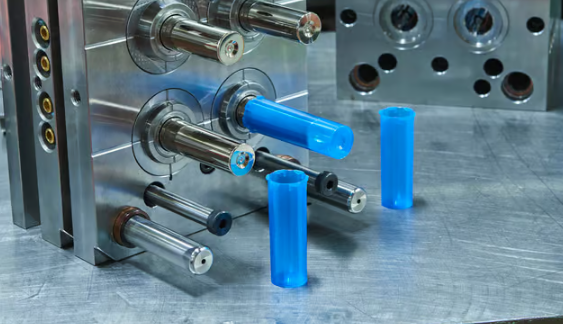

Injection molding is a widely used manufacturing process for producing plastic parts across various industries. Its popularity stems from its ability to produce large volumes of identical parts with high precision and speed.

Overview of Injection Molding Process

The injection molding process involves melting plastic pellets and injecting the molten plastic into a mold at high pressure. This process is highly efficient, typically taking only about 15-120 seconds per cycle, depending on the complexity and size of the part. The power consumption of the machinery used can range from 15 kW to 400 kW, significantly impacting the overall cost of production.

A key factor in this process is the cooling time, which varies based on the material and part design but generally accounts for about 50-80% of the cycle time. The faster the cooling, the quicker the production cycle, leading to increased efficiency and reduced costs.

Key Advantages:

High Production Speed: Injection molding machines can produce parts at a rapid pace, often creating thousands of parts per day.

Precision and Consistency: The process allows for high accuracy in dimensions, with tolerances as tight as ±0.005 inches.

Versatility: A wide range of materials and colors can be used.

Key Disadvantages:

High Initial Cost: The cost of injection molding machinery and molds can be significant, often ranging from $10,000 to $200,000.

Material Limitations: Not all plastics are suitable for injection molding due to their melting points and chemical properties.

Types of Plastics Commonly Used in Injection Molding

Different plastics offer various properties like strength, flexibility, and heat resistance, influencing their applications.

Polyethylene (PE): Widely used due to its low cost (around $1-$2 per pound) and versatility. It’s ideal for packaging and containers. Polyethylene – Wikipedia

Polypropylene (PP): Known for its flexibility and resistance to chemicals, with a price range of $1-$3 per pound. Commonly used in automotive parts and consumer goods. Polypropylene – Wikipedia

Polystyrene (PS): Offers excellent clarity and stiffness at a lower cost ($1-$2 per pound), making it suitable for disposable cutlery and CD cases. Polystyrene – Wikipedia

Acrylonitrile Butadiene Styrene (ABS): A higher-priced option ($2-$4 per pound) known for its toughness and impact resistance, commonly used in electronic housings and automotive components. ABS Plastic – Wikipedia

Each plastic type has its unique characteristics and cost implications, requiring careful selection based on the intended application, budget, and desired properties of the final product.

Evaluating the Cost of Plastics for Injection Molding

Understanding the cost dynamics of plastics used in injection molding is crucial for manufacturers to make informed decisions and optimize their budget.

Factors Influencing the Cost of Plastic Materials

Several factors significantly impact the cost of plastic materials used in injection molding:

Raw Material Prices: Fluctuations in the market can cause prices to vary significantly.

Material Quality: Higher quality materials typically cost more but offer better properties and longevity.

Quantity Purchased: Bulk purchases often lead to lower per-unit costs.

Type of Plastic: Different plastics have different prices based on their properties and production costs.

Key Consideration: Selecting the right type of plastic based on application needs and budget constraints is essential.

Comparison of Material Costs

The following table provides a detailed comparison of various plastics commonly used in injection molding, including their costs and key properties:

| Plastic Type | Cost per Pound | Advantages | Disadvantages | Common Applications |

|---|---|---|---|---|

| Polyethylene (PE) | $1 – $2 | Versatile, Durable | Limited heat resistance | Packaging, Containers |

| Polypropylene (PP) | $1 – $3 | Flexible, Chemical Resistant | Prone to UV degradation | Automotive Parts, Consumer Goods |

| Polystyrene (PS) | $1 – $2 | Clear, Stiff | Brittle | Disposable Cutlery, CD Cases |

| ABS | $2 – $4 | Tough, Impact Resistant | Higher cost | Electronic Housings, Automotive Components |

For more in-depth information on these plastics, refer to their respective Wikipedia pages.

Cheapest Plastics for Injection Molding

In the world of injection molding, cost efficiency is paramount. Identifying the most economical plastics without compromising on quality is a key step in optimizing production.

Identifying the Most Cost-Effective Plastics

When it comes to cost-effectiveness, certain plastics stand out in the injection molding industry:

Polyethylene (PE): Known for its low cost (approximately $1 to $2 per pound), PE is a versatile material offering good durability. However, its limitation lies in its low heat resistance.

Polypropylene (PP): With a price range of $1 to $3 per pound, PP is appreciated for its flexibility and chemical resistance. Its main disadvantage is its tendency to degrade under UV exposure.

Polystyrene (PS): Priced around $1 to $2 per pound, PS is favored for its clarity and stiffness, although it is relatively brittle.

Crucial Point: While these plastics are cost-effective, choosing the right type depends on the specific requirements of the product, including durability, flexibility, and resistance to environmental factors.

Properties and Applications of Low-Cost Plastics

Polyethylene (PE)

Properties: Durable, flexible, moisture-resistant.

Applications: Widely used in packaging, containers, and household items.

Limitation: Not suitable for high-temperature applications.

Polypropylene (PP)

Properties: Resistant to chemicals, flexible, good fatigue resistance.

Applications: Ideal for automotive parts, consumer goods, and medical equipment.

Drawback: UV sensitivity can limit outdoor applications.

Polystyrene (PS)

Properties: Excellent clarity, stiff and cost-effective.

Applications: Common in disposable cutlery, CD cases, and insulation materials.

Con: Its brittleness can be a limiting factor for certain applications.

For detailed insights on these plastics, consider exploring their Wikipedia pages.

Quality and Performance Considerations

The selection of plastics for injection molding involves a critical balance between cost, quality, and performance. This balance is essential for ensuring the final product meets the required standards while remaining economically feasible.

Impact of Using Cheaper Plastics on Product Quality

Using more affordable plastics in injection molding can significantly impact product quality in several ways:

Durability: Cheaper plastics might have a lower lifespan, potentially reducing the product’s life expectancy by 20-30% compared to higher-quality materials.

Precision and Tolerance: Economical plastics often have greater variability in their melting points and cooling rates, leading to a deviation in tolerances by approximately ±0.1 mm, affecting the fit and function of the parts.

Aesthetic Quality: Lower-cost materials can result in a 15-25% decline in surface finish quality, impacting color consistency and overall appearance.

Critical Insight: While cost-saving is a priority, it’s vital to consider the potential 10-20% increase in customer dissatisfaction and return rates due to quality issues.

Balancing Cost and Performance in Plastic Selection

To effectively balance cost and performance:

Application Requirements: For products exposed to high stress or temperatures, choosing a plastic that withstands these conditions is crucial, even if it’s 10-15% more expensive.

Long-Term Cost Implications: Consider the potential 30-40% increase in warranty claims and replacement costs due to lower-quality materials.

Blending Options: Blending can reduce costs by 5-10% while maintaining a 90-95% level of the desired material properties.

Refer to Plastic Properties – Wikipedia for detailed material properties.