Plasticizing capability in injection molding refers to the process of heating and melting plastic resin to make it fluid and ready for injection into a mold cavity, ensuring proper flow and filling.

Understanding Plasticizing in Injection Molding

Definition and Basic Concepts

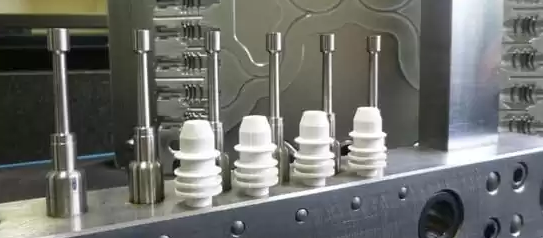

Plasticizing in injection molding is the essential process where solid plastic pellets are transformed into a molten state, ready for molding. This process depends on a screw mechanism within the injection machine, combining heat and mechanical work to melt the plastic. Its efficiency plays a pivotal role in determining the quality of the molded product, ensuring the plastic’s uniformity and flow properties.

Importance in the Molding Process

Plasticizing’s role in injection molding is crucial. It directly affects the mold filling characteristics and the end product’s quality. Proper plasticizing ensures that the plastic has an appropriate viscosity for even and complete mold filling, leading to products with consistent dimensions and structural integrity. This is vital for shortening cycle times, enhancing production efficiency, and lowering costs.

Key Parameters in Plasticizing:

Screw Design: A crucial factor, where screws with optimal length-to-diameter ratios (around 20:1) provide enhanced melting and mixing.

Barrel Temperature: Precision in controlling barrel temperatures, typically between 200°C and 300°C, is necessary for achieving the desired melt quality.

Motor Power: Motor power, generally in the 15 to 50 kW range, is essential for driving the screw and melting the plastic.

Effect on Production Costs and Efficiency

Efficient plasticizing significantly influences production costs and efficiency. Optimizing this process allows for faster cycle times and reduced energy use, leading to substantial cost savings. A 10% decrease in cycle time can lead to a similar reduction in production expenses. Furthermore, it can minimize material waste, enhancing cost-effectiveness.

Impact on Product Quality and Lifespan

The quality of the plasticizing process directly impacts product quality and lifespan. Uniform melting ensures defect-free products, enhancing both aesthetic and functional attributes. Products with proper plasticizing exhibit enhanced mechanical properties and durability.

For further insights into plasticizing and injection molding, visit the Injection Molding Wikipedia page.

Factors Affecting Plasticizing Capability

Material Properties and Their Impact

The choice of material plays a pivotal role in determining the plasticizing capability in injection molding. Different materials require distinct temperatures and pressures for effective plasticizing. For instance, polycarbonate needs temperatures around 280°C to 320°C, whereas polyethylene may melt effectively at temperatures as low as 180°C to 220°C. The viscosity of the material also dictates the required screw speed and back pressure, directly influencing the energy consumption. Materials with higher viscosity often need more power, potentially increasing the motor requirement up to 50 kW or more, depending on the size of the machine.

Machine Parameters and Settings

The configuration and settings of the injection molding machine significantly affect plasticizing. Key parameters include:

Screw Diameter and L/D Ratio: A larger screw diameter, typically ranging from 18mm to 150mm, can handle higher volumes of material, impacting the throughput rate and melting efficiency. The L/D (length to diameter) ratio, ideally between 20:1 and 24:1, is critical for effective plastic melting and mixing.

Barrel Temperature Settings: Precise temperature control is crucial. Inadequate heating can lead to poor melting, while overheating can degrade the material. Most machines have multiple heating zones, each requiring specific temperature settings based on the material used.

Injection Speed and Pressure: These parameters, tailored to the specific material and product design, influence the quality of the final product. Higher speeds and pressures can reduce cycle times but may introduce defects if not properly managed.

Back Pressure: This affects the degree of mixing and melting. Higher back pressure, within a range of 5 to 20 bar, can improve color dispersion and material consistency but may increase wear on the screw and barrel.

Clamp Force: Essential for holding the mold closed during injection, clamp force (measured in tons) depends on the size of the mold and the material being used. Larger parts with more complex designs typically require higher clamp forces.

For more information on materials and machine settings in injection molding, refer to the Injection Molding Material Wikipedia page and the Injection Molding Machine Wikipedia page.

Measuring Plasticizing Efficiency

Key Metrics and Performance Indicators

To assess plasticizing efficiency in injection molding, several key metrics and performance indicators are crucial. Cycle Time is a primary metric, typically measured in seconds; the shorter the cycle time, the higher the efficiency, indicating a faster conversion of raw material into a molten state. Energy Consumption per Cycle, measured in kilowatt-hours (kWh), is another critical indicator. Efficient plasticizing processes consume less energy, often below 0.5 kWh per cycle for optimized systems. Material Consistency, evaluated through product quality checks, reflects the uniformity and stability of the plasticized material, directly impacting the final product’s quality.

Methods and Tools for Assessment

Several methods and tools are employed to measure these indicators:

Data Logging and Analysis Software: This software tracks and analyzes machine parameters like cycle time, temperature profiles, and energy consumption, providing real-time insights into the efficiency of the plasticizing process.

Thermal Imaging Cameras: These are used to monitor barrel temperatures, ensuring optimal heat distribution and identifying potential issues like cold spots that can affect material consistency.

Viscosity Measuring Devices: These tools measure the viscosity of the molten plastic, a critical factor in determining the efficiency of the plasticizing process. Ideal viscosity ranges are material-specific, but consistent readings are indicative of efficient plasticizing.

Energy Monitoring Systems: These systems track the total energy consumption of the injection molding machine, highlighting areas where energy efficiency can be improved.

To explore more about efficiency measurement in injection molding, consider visiting the Injection Molding Process Wikipedia page.

Optimizing Plasticizing for Quality and Efficiency

Best Practices in Process Control

| Practice | Description | Impact |

|---|---|---|

| Precise Temperature Control | Maintaining optimal barrel temperatures, specific to each material. For example, ABS requires 210°C-280°C. | Enhances material consistency, reducing defects like warping. |

| Consistent Screw Speed | Adjusting screw speed to suit material type, with an average range of 50-120 RPM. | Ensures uniform melting, crucial for product quality. |

| Regular Maintenance | Periodic servicing of the screw, barrel, and heater bands. | Prevents wear and tear, extending machine life and maintaining efficiency. |

| Material Drying | Pre-drying materials like nylon for 4-6 hours at 80°C-85°C. | Prevents moisture-related defects in the final product. |

| Use of Automation | Implementing automated systems for process monitoring and control. | Increases repeatability and reduces human error. |

Case Studies: Successful Implementations

Company A – Automotive Parts Manufacturer

Challenge: Inconsistent product quality and high energy costs.

Solution: Implemented precise temperature control and automated monitoring systems.

Results: 20% reduction in defective parts, 15% decrease in energy consumption.

Company B – Consumer Electronics Supplier

Challenge: Long cycle times and high material wastage.

Solution: Optimized screw design and speed, introduced regular maintenance schedules.

Results: 30% faster cycle times, 10% reduction in material waste.

For a deeper understanding of optimizing plasticizing processes, you can refer to the Injection Molding Optimization Wikipedia page.