The size limitations of injection molding depend on factors like machine tonnage, mold design, and material, typically ranging from small parts to larger, complex components.

Fundamentals of Size Limitations in Injection Molding

Physical Constraints of Injection Molding Machines

Injection molding machines come with inherent physical limitations that directly impact the size of parts they can produce. A key parameter is the clamping force, which ranges typically from 5 to 6,000 tons. Larger clamping forces allow for bigger parts but also increase the machine’s size, cost, and power consumption. The size of the machine’s platens and the distance between tie bars also dictate the maximum mold size. For instance, a machine with a 500-ton clamping force might have a maximum mold size of about 48 inches by 48 inches.

Material Flow and Cooling Time Considerations

Material flow within the mold is crucial for determining the size limitations of injection molded parts. Materials with high fluidity can fill larger molds more easily, affecting the quality and consistency of larger parts. Cooling time also plays a vital role in defining size constraints. Larger parts require longer cooling times, which can slow down production speeds and increase costs. For example, a part that is twice as large in volume may need up to four times longer to cool, significantly affecting production efficiency.

Design Strategies for Large Complex Parts

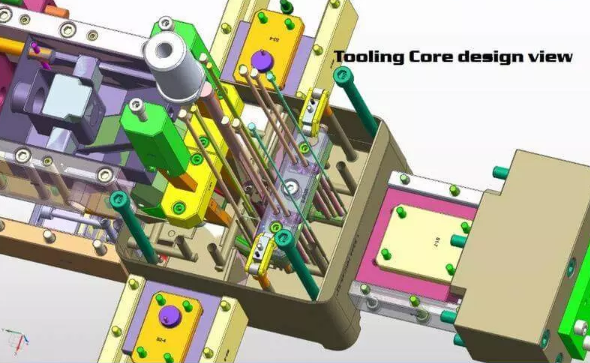

Designing for large complex parts in injection molding requires balancing size with moldability. Utilizing advanced simulation software helps in predicting material flow and cooling behavior in larger molds. Innovative mold designs, like those with collapsible cores or sliding mechanisms, can facilitate the creation of large parts with complex features. However, these designs often come at a higher cost and may require more maintenance, impacting the overall value and lifespan of the mold.

Trade-offs Between Size and Part Complexity

The relationship between size and complexity in injection molded parts is often a trade-off. Achieving larger sizes might necessitate simplifying part designs to ensure quality and manufacturability. Conversely, highly complex designs may need to be scaled down to fit within the physical and material flow limitations of the molding process. For instance, a part with intricate details and undercuts might be limited to a smaller overall size to ensure proper material flow and cooling.

For further detailed insights, the Injection Molding page on Wikipedia provides extensive information on materials and processes used in this field.

Maximizing the Size in Injection Molding

Techniques for Large Part Molding

Large part molding requires specialized techniques to ensure quality and efficiency. Increased machine size is a primary factor; machines with a clamping force of 2000 to 6000 tons are commonly used for larger parts. This increased size, however, leads to higher power consumption, often reaching up to 180 kW. Utilizing gas-assist molding is another technique, which reduces material use while maintaining part integrity, thus cutting down on material costs significantly.

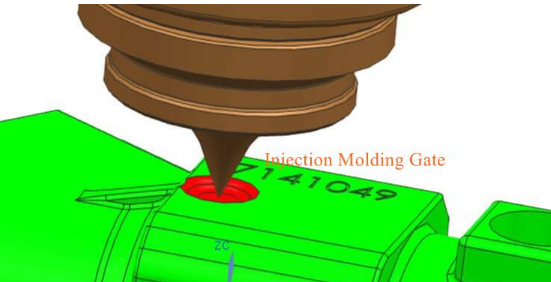

Sequential valve gating has revolutionized large part molding. By controlling the flow of material into the mold, this technique ensures uniform cooling and material distribution, crucial for large parts. While this increases the complexity and cost of the mold, it significantly enhances the quality of the final product.

Optimizing Mold Design for Larger Sizes

When it comes to mold design for larger sizes, optimization is key. Larger molds require robust design to withstand the high pressure of the injection molding process. The cost of these molds can be substantial, often several tens of thousands of dollars, depending on the complexity. Ensuring proper cooling channels within the mold is critical; inadequate cooling can lead to warping or surface defects in large parts.

Innovative cooling techniques, like conformal cooling, which involves designing cooling channels that follow the shape of the part, can significantly reduce cooling times and improve part quality. 3D printing of mold inserts is a cost-effective way to implement complex cooling channels, especially beneficial for large parts. This technique not only improves cooling efficiency but also reduces the overall cycle time, enhancing production speed.

Maintaining a balance between size, cost, and quality is crucial in large part injection molding. Large molds come at a high cost, but by employing advanced techniques like sequential valve gating and innovative cooling methods, manufacturers can produce large parts efficiently without compromising on quality. For a comprehensive understanding of these techniques, the Injection Molding Machine page on Wikipedia offers valuable insights into the machinery and processes involved.

Limitations and Solutions for Small Parts

Challenges in Molding Small Precision Parts

| Challenge | Description | Impact |

|---|---|---|

| High Precision Requirement | Small parts often require precise dimensions, which is challenging to achieve consistently. | Leads to higher rejection rates and increased costs. |

| Material Behavior | Smaller parts mean less material, which cools faster, affecting flow and setting. | Can result in defects or weak parts if not controlled properly. |

| Tooling Complexity | The molds for small parts are intricate, making them difficult and expensive to manufacture. | Increases initial investment and maintenance costs. |

Advanced Technologies for Small Part Molding

| Technology | Description | Benefits |

|---|---|---|

| Micro-Injection Molding | A specialized form of molding for producing extremely small, high-precision parts. | Allows for high precision with reduced waste and lower material costs. |

| High-Speed Robotics | Automated systems for handling and processing small parts at high speeds. | Enhances production efficiency and reduces labor costs. |

| 3D Printing for Mold Making | Using 3D printing to create complex mold designs for small parts. | Reduces mold-making costs and allows for more intricate designs. |

For an in-depth understanding of the intricacies involved in small part molding, the Micro-Injection Molding page on Wikipedia offers valuable insights.

Influence of Materials on Size Capabilities

Material Properties and Their Impact on Sizing

In injection molding, different materials have unique properties that affect part size and quality:

Polypropylene (PP): Ideal for large parts due to high flowability. Melting point around 130°C to 171°C, which allows for easier flow in the mold. However, it’s not suited for small, detailed parts due to lower strength.

Polyethylene (PE): Offers high strength, but requires higher injection pressures. Suitable for parts requiring durability, but may limit the maximum size due to the high pressure needed.

ABS (Acrylonitrile Butadiene Styrene): Prone to warping due to a high thermal expansion coefficient (approximately 80 x 10^-6 /°C), limiting its use in large parts where dimensional stability is crucial.

Nylon: Known for slow cooling rates, extending cycle times. For example, a Nylon part might take 30-50% longer to cool than a comparable PP part, impacting production efficiency.

Selecting the Right Material for Size Requirements

Choosing materials for different size requirements involves balancing properties, cost, and molding conditions:

High Impact Polystyrene (HIPS): Used for large parts due to good flowability and strength balance. It has a melting point around 180°C to 270°C, making it easier to mold into larger shapes.

Acetal (Polyoxymethylene, POM): Preferred for small precision parts. It offers high strength and stiffness, with a melting point of 175°C to 185°C. However, it’s more expensive, with prices ranging from $1.50 to $2.50 per pound.

PEEK (Polyether Ether Ketone): High-performance material with exceptional properties, suitable for extreme conditions. However, it’s costly, with prices up to $100 per pound, and requires high processing temperatures (343°C to 400°C).

Cost and Efficiency Considerations:

Materials like PEEK or Ultem, despite their superior properties, increase production costs significantly. For instance, using PEEK can increase the cost of a part by 20-40% compared to more standard materials like PP or PE.

Material choice also impacts cycle time and energy consumption. For example, molding with ABS might consume 10-15% more energy than PP due to its thermal properties and processing requirements.

In summary, material selection in injection molding is a critical factor that influences the size, quality, and cost of the produced parts. The Injection Molding Material Selection guide on Wikipedia provides further insights into the properties and applications of various materials.