Some common problems with injection molding include warping, surface defects, material compatibility issues, and tooling wear.

Understanding Injection Molding

Basic Process Overview

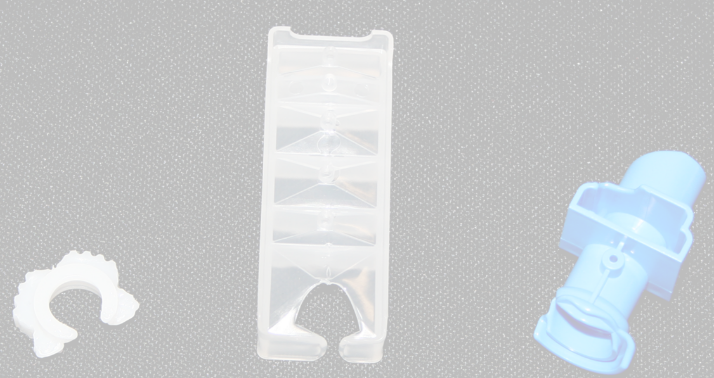

In the manufacturing world, injection molding stands out as a method for producing parts by injecting molten material into a mold. This process begins with melting the raw material, followed by injecting it into a mold. Then, cooling the material shapes it, and finally, the finished part gets ejected. Its popularity stems from the ability to mass-produce identical parts with impressive precision and minimal waste.

Key Parameters

Cycle Time: Typically varies between 15 to 60 seconds, playing a crucial role in production efficiency.

Mold Lifetime: High-quality molds often endure over 1 million cycles, representing a significant investment for long-term use.

Machine Power: The clamping force of injection molding machines ranges widely, from 15 to 6,000 tons, indicating their size and production capability.

Material Considerations:

Plastics: Manufacturers often choose materials such as Polypropylene (PP), Polyethylene (PE), and Acrylonitrile Butadiene Styrene (ABS) for their unique properties like durability, flexibility, and heat resistance.

Cost and Quality: Selecting the right material crucially affects both the cost and the quality of the final product. Material expenses can significantly vary, ranging from more economical options like polyethylene to pricier engineering plastics.

Common Materials Used

Choosing the right materials in injection molding is vital for achieving the desired product properties, maintaining cost-effectiveness, and ensuring manufacturing efficiency.

Material Properties

Temperature Tolerance: For products that endure heat, materials such as Polycarbonate (PC) are ideal due to their higher temperature resistance.

Strength and Durability: Tough materials like ABS are perfect for products requiring impact resistance.

Economic Factors

Cost-Effectiveness: For large-scale production, materials like polyethylene offer a balance between quality and affordability.

Recyclability: The growing environmental consciousness makes recyclable materials like PET increasingly important.

Speed and Efficiency:

Injection Speed: This varies depending on the material and machine, where faster speeds boost productivity but may compromise quality.

Energy Consumption: Opting for efficient machines can drastically cut down energy costs, a key consideration in large-scale production.

Focusing on these elements allows for optimizing injection molding processes for cost, quality, and efficiency, catering to various industrial requirements.

Mechanical Issues in Injection Molding

Machine Malfunctions and Maintenance

Injection molding machines are complex systems, and their effective operation is crucial for production. Common malfunctions include hydraulic system failures, control system glitches, and wear and tear of moving parts. Regular maintenance is essential to prevent downtime. For instance, hydraulic fluid levels and quality need monitoring, and control systems require regular updates and checks.

Maintenance Costs and Lifespan:

Costs: Routine maintenance may incur a moderate expense but significantly reduces the risk of costly major repairs.

Lifespan: A well-maintained machine can last up to 20 years, ensuring a good return on investment.

Efficiency and Energy Consumption:

Efficiency Loss: Machine malfunctions can decrease efficiency, leading to longer cycle times and increased energy use.

Energy Costs: Older machines often consume more energy. Upgrading to newer, more efficient models can lead to substantial energy savings.

Mold Design Flaws and Limitations

The design of the mold in injection molding is as critical as the machine itself. Design flaws such as improper cooling channels or inadequate venting can lead to defects in the final product. Mold precision is vital for product consistency.

Mold Cost and Material:

Cost Range: Mold costs vary significantly, from a few thousand dollars for simple designs to hundreds of thousands for complex ones.

Materials Used: Common mold materials include P20 steel and aluminum, each offering different benefits in terms of durability and heat transfer.

Size and Specifications:

Dimensions: Molds can range in size from a few centimeters to several meters, depending on the part being produced.

Specifications: Precision in mold dimensions is crucial, as even minor deviations can lead to product defects.

By addressing these mechanical aspects diligently, manufacturers can greatly enhance the quality and efficiency of their injection molding operations.

Material-Related Challenges

Issues with Plastic Quality and Consistency

| Aspect | Detail | Impact on Production |

|---|---|---|

| Material Purity | Variations in material purity can lead to inconsistent product quality. For instance, contaminants in the plastic can cause defects. | Quality control becomes challenging, leading to potential rejections and increased waste. |

| Melting Behavior | Different plastics have varying melting points. For example, Polypropylene melts at around 130-171°C. | Incorrect temperature settings can lead to improper melting, affecting the product’s structural integrity. |

| Material Costs | Costs of raw materials can fluctuate. High-quality plastics like Polycarbonate are more expensive. | Increases in material costs directly impact the overall production budget. |

Speed and Efficiency Considerations:

Cycle Time: The quality of the material can affect the cycle time, with higher quality materials often allowing for faster processing.

Efficiency: Consistent material quality ensures steady production efficiency, reducing downtimes and defects.

Environmental Impact of Materials

| Aspect | Detail | Environmental Concern |

|---|---|---|

| Recyclability | Not all plastics are easily recyclable. Materials like PET are more environmentally friendly. | Non-recyclable plastics contribute to landfill waste and environmental pollution. |

| Biodegradability | Many plastics are not biodegradable. Bioplastics offer an alternative. | Traditional plastics can take hundreds of years to decompose, posing long-term environmental hazards. |

| Energy Consumption | The production of plastics, especially more durable types, requires significant energy. | Higher energy consumption during production contributes to a larger carbon footprint. |

Cost and Sustainability Balance:

Material Selection: Choosing environmentally friendly materials can be more costly but is crucial for sustainable production.

Long-term Value: Investing in sustainable materials can enhance the brand image and appeal to environmentally conscious consumers.

By thoroughly addressing these material-related challenges, manufacturers can optimize both the quality of their products and their environmental impact.

Quality Control in Injection Molding

Defects and Imperfections in Final Products

In the realm of injection molding, vigilance in quality control is paramount, aiming to minimize defects and imperfections that can range from minor aesthetic flaws to significant structural failures, thus impacting the product’s functionality and integrity.

Types of Defects and Their Frequencies

Flash: Excess material oozing out of the mold cavity, occurring in approximately 5-10% of products if not controlled. Usually caused by excessive injection speed or high pressure.

Warping: Deformation observed in about 8-12% of products, occurring when parts of the component cool unevenly.

Sink Marks: Surface indentations found in around 6-9% of products, often due to insufficient cooling time or material density inconsistencies.

Impact on Production Costs

Increased Waste: Defective products can lead to a waste increase by up to 15%, escalating material costs.

Rework Labor: Sorting and fixing defective items can add an additional 10-20% in labor costs.

Balancing Efficiency with Quality:

Inspection Procedures: Implementing rigorous inspection can improve product quality by up to 30%.

Automated Quality Control Systems: These systems can enhance defect detection accuracy by 25% and improve overall efficiency.

Precision and Reproducibility Concerns

Achieving high precision and reproducibility is crucial in injection molding, especially for products requiring strict adherence to specifications, like in the medical or automotive industries.

Precision Factors and Their Cost Implications

Mold Design Accuracy: Precision in mold design, which can cost 20-30% more, ensures that each part adheres to intended dimensions within a tolerance of ±0.5%.

Machine Calibration: Regular calibration, increasing operational costs by 5-10%, is necessary to maintain consistent quality.

Challenges in Reproducibility

Material Variability: Fluctuations in material properties can affect part consistency by up to 15%.

Environmental Influences: Changes in temperature and humidity can impact the molding process, potentially varying product quality by 10-20%.

Cost-Efficiency in Precision Maintenance:

Quality Mold Investment: High-quality molds, though 20-30% more expensive, lead to better precision and reduced long-term costs due to 10-15% lower waste and rework rates.

Regular Equipment Maintenance: Consistent maintenance can reduce breakdown risks by up to 25% and ensure ongoing accuracy.

By emphasizing quality control in defect management and precision, manufacturers can significantly bolster the reliability and market reputation of their injection-molded products.