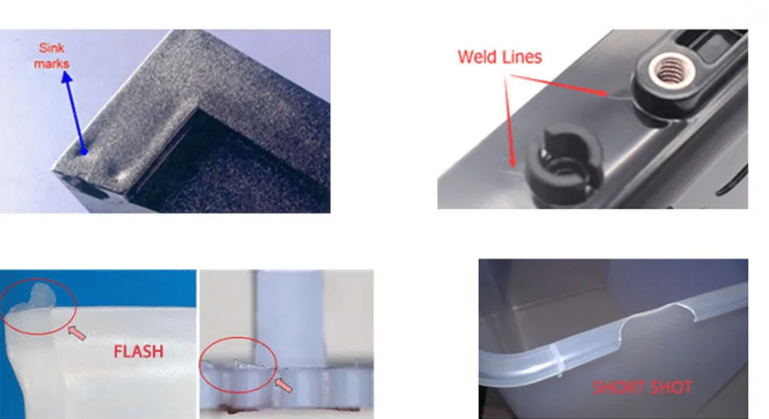

Common defects in injection molding products include sink marks, warping, short shots, flash, burn marks, and dimensional inaccuracies.

Types of Defects in Injection Molding Products

Surface Imperfections

Surface imperfections significantly impact the aesthetic and functional quality of injection molding products. Key surface defects include:

Sink Marks: These depressions occur when the inner part cools faster than the outer surface, typically appearing on thicker sections (>0.125 inches).

Weld Lines: Formed at points where two flow fronts meet, resulting in lines that can weaken the part by up to 25% in strength.

Scorch Marks: Burn-like marks that appear when plastic overheats, often at temperatures exceeding the material’s safe processing range by 10-15%.

Structural Weaknesses

Structural weaknesses compromise product integrity and durability. Common structural defects involve:

Stress Cracking: Caused by internal stresses, often in parts with wall thickness variations exceeding 10%.

Delamination: Layers separating due to contamination or poor mixing, reducing part strength by up to 30%.

Brittleness: Occurs when plastic doesn’t reach optimal flexibility, often due to processing temperatures being 5-10% outside the recommended range.

Dimensional Inaccuracies

Precise dimensions are vital for molded product functionality. Typical dimensional issues are:

Shrinkage: A size reduction from mold dimensions, typically between 0.5% and 3%, varying with material type.

Warpage: Distortion due to uneven cooling or material inconsistencies, potentially altering dimensions by 1-2%.

Flash: Excess material leaking out, usually less than 0.005 inches, but impacting fit and function.

For detailed insights, the Wikipedia page on Injection Molding offers more information.

Causes of Surface Defects

Sink Marks and Voids

Sink marks and voids occur when there is insufficient cooling and material in thicker areas of the part. Main causes include:

Insufficient Cooling: Parts with thicknesses over 0.125 inches often cool unevenly, leading to sink marks.

Inadequate Material: When the molten plastic doesn’t fill the mold completely, voids form, usually in thicker sections.

High Injection Speed: Speeds over the optimal range can trap air and create voids.

Flash and Short Shots

Flash and short shots arise from improper mold filling and sealing. Primary reasons are:

Improper Clamping Force: Clamping forces below the required range (5 to 6,000 tons) can cause flash along part edges.

Incorrect Material Volume: Short shots happen when injected material volume is 5-10% less than needed for the mold.

Uneven Material Flow: Variations in flow can lead to incomplete filling, especially in intricate designs.

Burn Marks and Warping

Burn marks and warping are due to excessive heat and uneven cooling. Key factors include:

Overheating: Temperatures exceeding the material’s safe range by 10-15% cause burn marks.

Inconsistent Cooling: Cooling times less than the optimal range lead to warpage, especially in parts with a 1-2% variation in wall thickness.

High Injection Speed: Speeds above recommended levels can generate friction heat, contributing to burn marks.

For more information, the Wikipedia page on Injection Molding offers additional insights.

Structural Defects and Their Origins

Stress Cracking and Brittleness

Stress cracking and brittleness in injection molded products often compromise their durability and longevity. Primary causes are:

Excessive Residual Stress: Stress cracking typically appears in areas where residual stress exceeds 10-15% of the material’s strength.

Inadequate Plasticization: Brittleness can result when the material is not properly plasticized, often occurring if the processing temperature is 5-10% below the material’s optimal range.

Rapid Cooling: Cooling rates that are too fast can induce brittleness, particularly in parts thicker than 0.15 inches.

Delamination and Bubbles

Delamination and bubble formation affect the structural integrity of molded products. Key reasons include:

Material Contamination: Even 1-2% of foreign material can lead to delamination, weakening the product’s structure.

Improper Venting: Inadequate venting in the mold can trap air, causing bubbles, especially in parts with intricate geometries.

Inconsistent Material Flow: Uneven flow, often due to variations in injection speed, can create layers within the material, leading to delamination.

For more detailed information, the Wikipedia page on Injection Molding provides comprehensive insights.

Dimensional Inaccuracy Issues

Shrinkage and Warpage

| Issue | Description | Typical Causes |

|---|---|---|

| Shrinkage | Reduction in size from mold dimensions, typically ranging between 0.5% and 3%, depending on the material. | Uneven cooling, material type, and mold temperature. |

| Warpage | Distortion of the part’s shape, potentially altering dimensions by 1-2%. | Inconsistent cooling, varying wall thickness, material properties. |

Uneven Wall Thickness

| Aspect | Impact on Product | Primary Causes |

|---|---|---|

| Thickness Variation | Variations over 10% can lead to uneven shrinkage, causing warpage and stress concentration. | Improper design, incorrect flow rate during injection. |

| Consistency | Consistent wall thickness is crucial for product integrity and quality. | Mold design, injection speed, and pressure settings. |

For further information, explore the Wikipedia page on Injection Molding.