Vacuum forming can be highly accurate, but it depends on material quality, mold precision, and the operator’s expertise.

Accuracy in Vacuum Forming

Vacuum forming, a versatile and cost-effective method for shaping plastic materials, hinges significantly on achieving high accuracy. This process involves heating a plastic sheet until it’s pliable, then using a vacuum to form it over a mold.

Key Components in Vacuum Forming

In vacuum forming, the accuracy of the final product depends on several components:

- Mold Precision: The mold’s dimensions and surface finish directly impact the accuracy of the formed plastic. A high-quality mold ensures that the plastic conforms precisely to the desired shape and specifications.

- Material Consistency: The uniformity of the plastic sheet, in terms of thickness and quality, plays a crucial role. Fluctuations in material quality can lead to inconsistencies in the final product.

- Heating Process: Uniform heating of the plastic sheet is critical. Uneven heating can cause warping or incomplete forming, affecting the final product’s accuracy.

- Vacuum Efficiency: The strength and consistency of the vacuum applied to draw the plastic sheet into the mold must be optimal. Insufficient vacuum pressure can result in incomplete or inaccurate forming.

Factors Influencing Accuracy

Several factors influence the accuracy of vacuum-formed products:

- Material Type: Different plastics have varying properties that affect how they react to heat and forming. Materials like polystyrene and PVC have distinct behaviors under vacuum forming conditions.

- Temperature Control: Precise temperature control ensures uniform plasticity of the material, crucial for accurate forming.

- Mold Design and Complexity: Complex molds with intricate details require more precision in the vacuum forming process. The design and manufacturing quality of the mold are paramount.

- Operator Skill: The expertise and experience of the operator play a vital role in managing the nuances of the vacuum forming process.

Measuring Accuracy in Vacuum Forming

To ensure high accuracy in vacuum forming, measurement and quality control are essential.

- Dimensional Inspection: Using tools like calipers and micrometers, technicians measure the dimensions of the vacuum-formed product to ensure they match the design specifications.

- Surface Quality Analysis: Examining the surface finish and detailing of the formed product is crucial. Any defects or deviations from the intended design indicate issues in the forming process.

- Tolerance Testing: Products are tested against predefined tolerance levels. For instance, a product with dimensions that must be within ±0.5 mm of the design specifications requires precise forming techniques.

- Continuous Improvement: Feedback from these measurements informs adjustments in the process, aiming for incremental improvements in accuracy.

Materials and Their Impact on Accuracy

The choice of material in vacuum forming significantly influences the accuracy and quality of the final product. Different materials exhibit unique properties under heat and vacuum, affecting the precision with which they conform to mold shapes.

Material Properties and Forming Precision

- Thermal Behavior: Materials react differently to heat. For instance, ABS plastic softens at a different rate compared to polycarbonate, affecting how well they can be stretched and formed over a mold.

- Material Memory: Some plastics have a tendency to return to their original shape, impacting the final accuracy. Materials with lower memory ensure better dimensional stability post-forming.

- Durability and Flexibility: The inherent strength and flexibility of a material determine its ability to maintain shape and resist warping, both critical for precision.

Influence of Material Thickness

- Uniform Thickness: Consistency in material thickness is crucial. Variations can lead to uneven forming and dimensional inaccuracies.

- Thickness and Detail Resolution: Thinner materials can capture finer details of the mold, while thicker materials might struggle with intricate designs.

Common Materials Used in Vacuum Forming

| Material | Properties | Typical Applications | Accuracy Potential |

|---|---|---|---|

| ABS | Durable, Impact-resistant | Automotive parts, housings | High |

| Polystyrene | Lightweight, Cost-effective | Packaging, disposable containers | Moderate |

| Polycarbonate | High strength, Heat resistant | Protective gear, medical devices | Very High |

| PVC | Chemical resistant, Flexible | Piping, medical equipment | Moderate |

| PETG | Clear, Food-safe | Food packaging, retail displays | High |

| Acrylic | High clarity, Scratch-resistant | Signage, skylights | High |

This table summarizes key materials in vacuum forming, highlighting their unique properties and the resulting accuracy in forming applications.

How Material Choices Affect Precision

- Heat Resistance and Shaping: Materials with higher heat resistance can withstand more precise heating cycles, leading to more accurate forming.

- Material Stability: Materials that maintain their shape and dimensions after cooling are essential for high-precision applications.

- Detail Reproduction: The ability of a material to reproduce fine details of the mold depends on its flexibility and softening point.

Techniques to Enhance Accuracy in Vacuum Forming

Optimizing the accuracy in vacuum forming involves a combination of advanced techniques, precise calibration, and alignment methods. These approaches aim to minimize errors and enhance the quality of the final product.

Advanced Vacuum Forming Techniques

Precision Control Systems: Implementing state-of-the-art control systems can significantly improve accuracy. These systems precisely regulate temperature, vacuum pressure, and timing, reducing the margin of error. For example, maintaining temperature within a range of ±2°C can enhance the forming precision.

Automated Material Handling: Automation in material handling ensures consistent placement and alignment of the plastic sheet. This consistency is crucial for achieving uniform thickness and reducing deformities.

3D Printing for Molds: Using 3D printed molds allows for greater detail and precision in mold design. This method is particularly effective for complex shapes, where traditional mold-making might fall short.

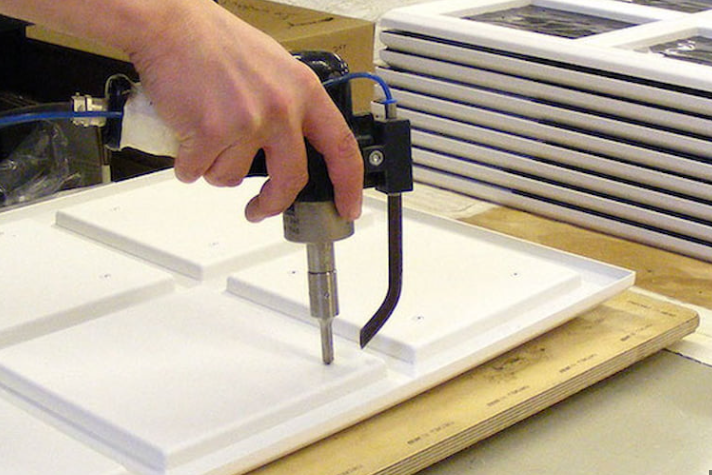

High-Speed Cutting Techniques: Post-forming, high-speed cutting tools provide precise trimming of the formed part. Laser cutting, for instance, offers accuracy up to ±0.1 mm, ensuring the final product adheres closely to the intended dimensions.

Calibration and Alignment Methods

Regular Calibration of Equipment: Regular calibration of forming machines ensures that they operate within specified parameters. For instance, calibrating the heating system to ensure even heat distribution prevents material warping and distortion.

Alignment Checks: Conducting routine alignment checks on the forming machine, particularly the alignment between the mold and the sheet, is critical. Misalignment, even by a few millimeters, can lead to significant inaccuracies in the final product.

Use of Precision Sensors: Integrating precision sensors to monitor the vacuum forming process in real time enables immediate adjustments. These sensors can detect deviations in temperature, pressure, and alignment, allowing for corrective measures to be taken promptly.

Quality Control Protocols: Establishing rigorous quality control protocols helps in early detection of inaccuracies. For instance, incorporating optical measuring systems can detect dimensional deviations with a precision of ±0.05 mm.

Challenges in Achieving High Accuracy in Vacuum Forming

Attaining high precision in vacuum forming is a complex process that comes with its own set of challenges. Understanding these challenges, the common pitfalls, and adopting effective strategies are key to enhancing accuracy.

Common Pitfalls and Errors

Inconsistent Material Quality: Variations in material properties, like thickness or composition, can lead to inconsistent forming. For example, a fluctuation in thickness by even 0.5 mm can significantly affect the final product’s accuracy.

Improper Heating: Uneven heating of the plastic sheet often results in warping or incomplete forming. Achieving a uniform temperature distribution is crucial for precise forming.

Mold Design Flaws: Molds with intricate details or undercuts can be challenging to replicate accurately. Any imperfection in the mold design, such as a slight misalignment or surface roughness, can be transferred to the formed product.

Environmental Factors: External factors like humidity or temperature variations in the workshop can impact the forming process. For instance, a change in ambient temperature by 10°C can alter the heating dynamics of the plastic.

Strategies to Overcome Accuracy Issues

Quality Control of Materials: Implementing strict quality control measures for materials, ensuring consistent thickness and properties, is essential. Regular testing and certification of materials can help maintain quality standards.

Advanced Heating Systems: Utilizing advanced heating systems that offer precise temperature control can mitigate issues related to uneven heating. Implementing a system that maintains temperature with a variance of less than ±1°C can significantly improve accuracy.

Precision Mold Design and Maintenance: Investing in high-quality molds and regular maintenance can reduce inaccuracies. Employing computer-aided design (CAD) for mold creation can enhance precision, particularly for complex shapes.

Environmental Control: Maintaining a controlled environment in terms of temperature and humidity can reduce the impact of external variables. Keeping the workshop temperature stable within a range of ±2°C can help achieve consistent results.

Regular Calibration and Alignment: Regularly calibrating and aligning the vacuum forming machine ensures that it operates within the desired parameters. Calibration should focus on alignment, temperature control, and vacuum pressure settings.

Employee Training and Expertise: Providing comprehensive training to operators on the nuances of vacuum forming and problem-solving can greatly enhance the accuracy of the process. Experienced operators are better equipped to identify and rectify potential issues quickly.