Injection molding is not exclusive to plastics; it’s also used for metals, silicones, rubbers, glass, and ceramics.

Fundamentals of Injection Molding

Definition and Basic Process of Injection Molding

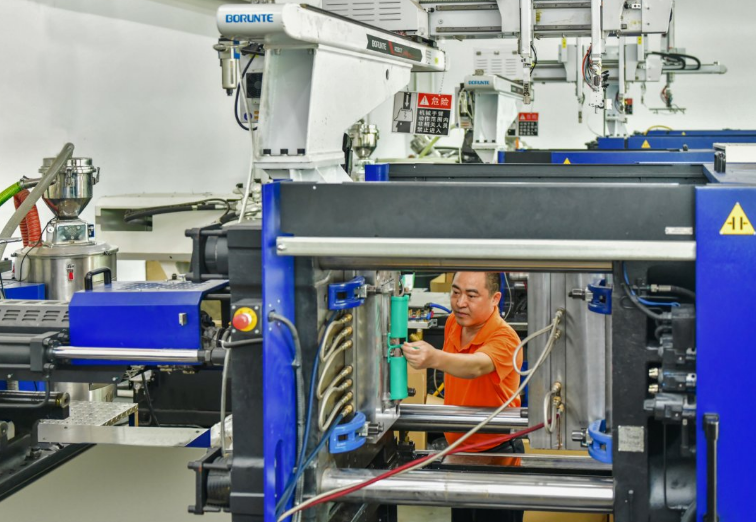

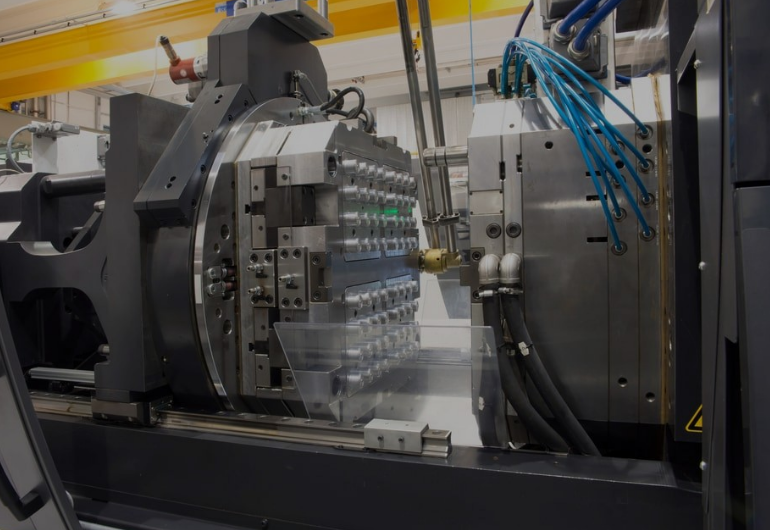

Injection molding serves as a key manufacturing technique for producing parts by injecting molten material into molds. Initially, the process begins by loading plastic pellets into a hopper. Then, these pellets move towards a heating chamber where they melt. The machine actively injects this molten plastic into a mold cavity using a high-pressure screw or ram injector. In the mold, the plastic cools and takes the mold’s shape. After solidifying, the mold opens and a mechanism ejects the part. This process excels in mass-producing consistent quality parts and typically completes in cycles. These cycles range from a few seconds to minutes, varying with part complexity and size.

Range of Materials Used in Injection Molding

| Material Type | Typical Applications | Advantages and Challenges |

|---|---|---|

| Thermoplastics | Consumer products, automotive parts | Highly versatile and recyclable, but may offer lower heat resistance |

| Thermosetting Plastics | Electrical insulators, tool handles | Excellent heat resistance and durability, but can’t be remelted |

| Elastomers | Seals, gaskets | Offer flexibility and durability, but require specific processing conditions |

| Metals (MIM) | Surgical tools, precision gears | Provide high strength and precision, but involve a more costly and complex process |

| Silicone | Medical devices, kitchenware | Heat resistant and flexible, but need specialized molds and curing processes |

For an in-depth look into injection molding, you can visit the Injection Molding Wikipedia page.

Plastics in Injection Molding

Types of Plastics Commonly Used

In injection molding, several types of plastics are prominent, each distinguished by specific properties and typical applications:

Polyethylene (PE):

Types: High-Density (HDPE), Low-Density (LDPE)

Properties: HDPE’s tensile strength is around 0.20 – 0.40 GPa, whereas LDPE ranges from 0.10 – 0.25 GPa.

Uses: HDPE for heavier-duty containers, LDPE for packaging films, bags.

Polypropylene (PP):

Tensile Strength: 30 – 40 MPa

Uses: Automotive parts, medical devices, textiles.

Polystyrene (PS):

Tensile Strength: 25 – 50 MPa

Uses: Disposable cutlery, CD cases, plastic models.

Acrylonitrile Butadiene Styrene (ABS):

Tensile Strength: 27 – 48 MPa

Uses: LEGO bricks, electronic housings, automotive parts.

Polycarbonate (PC):

Tensile Strength: 60 – 70 MPa

Uses: Bulletproof glass, eyewear lenses, medical devices.

Advantages of Using Plastics in Injection Molding

Plastics offer several benefits in injection molding:

Versatility: Engineered for specific needs – HDPE’s high strength for rugged applications, LDPE’s flexibility for packaging.

Cost-Effectiveness: Generally more economical than metals or ceramics. Energy consumption in molding processes is lower for plastics, with average processing temperatures for PP around 220 – 280°C compared to metals which can exceed 1600°C.

Production Speed: Quicker cooling and faster cycle times. For instance, the cycle time for PP can be as low as 20 seconds.

Design Flexibility: Easy molding into complex shapes. ABS, for example, is known for its excellent moldability.

Recyclability: Many plastics like PE and PP are recyclable, promoting environmental sustainability.

For detailed insights into plastics used in injection molding, the Injection Molding of Plastics Wikipedia page can be a valuable resource.

Alternative Materials in Injection Molding

Injection Molding with Metals: Metal Injection Molding (MIM)

Metal Injection Molding (MIM) expands the capabilities of traditional injection molding to metals. This process involves mixing metal powders with polymers to create a feedstock, which is then molded under high pressure. Common metals used include stainless steel, titanium, and nickel alloys. MIM allows for the production of complex geometries similar to plastic injection molding, with the added advantage of the strength and durability of metals. The process typically has a higher cost due to the materials and the sintering step required after molding. For example, the cost of MIM stainless steel parts can range from $0.20 to $2 per piece, depending on size and complexity.

Utilizing Silicone and Rubber in Injection Molding

Silicone and rubber materials bring unique properties to injection molding. These elastomers are ideal for creating flexible, durable parts like seals, gaskets, and medical devices. Silicone, with a wide operating temperature range (-55°C to 300°C), offers excellent heat resistance. Rubber materials like EPDM and Nitrile have varying degrees of heat, oil, and chemical resistance, suitable for specific applications. The injection molding of these materials involves lower pressures and temperatures compared to plastics, leading to different equipment and mold design considerations.

Exploring the Use of Glass and Ceramics

Glass and ceramics represent a niche but growing area in injection molding. These materials offer high heat resistance, electrical insulation, and corrosion resistance. The process, similar to MIM, combines glass or ceramic powders with a binder. It is particularly useful for creating intricate parts where traditional ceramic processing methods are impractical. The main challenge lies in the high cost and complexity of the process, as well as the need for post-molding sintering to achieve the final properties.

For more information on alternative materials in injection molding, the Metal Injection Molding Wikipedia page provides extensive insights.

Comparative Analysis of Materials in Injection Molding

Plastics vs. Metals: Pros and Cons in Injection Molding

| Material | Pros | Cons | Typical Applications |

|---|---|---|---|

| Plastics | Cost-effective;Versatile in design;Quick cycle times ;Lightweight | Less strength compared to metals ;Heat sensitivity | Consumer products, automotive components |

| Metals (MIM) | High strength and durability;Superior mechanical properties;Heat resistance | Higher cost – Longer cycle times ;Complex process | Surgical tools, aerospace components |

Suitability of Different Materials for Various Applications

| Material | Strengths | Limitations | Best Suited Applications |

|---|---|---|---|

| Silicones | Heat and chemical resistance;Flexibility;Biocompatibility | Lower mechanical strength;Higher material cost | Medical devices, cooking tools |

| Rubber | Elasticity;Durability;Oil resistance (Nitrile) | Not suitable for high;temperature applications | Seals, gaskets, hoses |

| Glass and Ceramics | High temperature and corrosion resistance;Electrical insulation | High production cost;Complex manufacturing | Electrical insulators, high-temperature applications |

For more detailed insights into materials used in injection molding, the Injection Molding Materials Wikipedia page can be a valuable resource.