To shorten cooling time in injection molding, optimize mold design, material properties, and cooling systems.

Understanding Cooling in Injection Molding

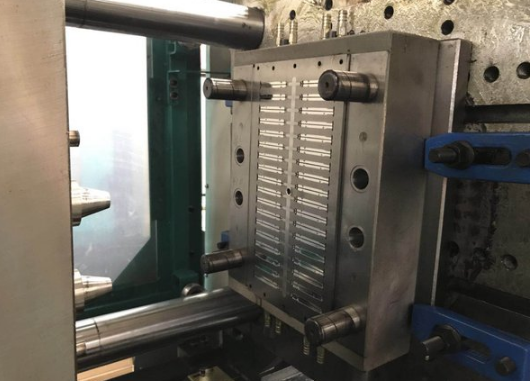

The cooling phase in injection molding is a critical process that significantly affects the overall efficiency and quality of the final product. Let’s delve into the role of cooling and the factors influencing cooling time.

The Role of Cooling in the Injection Molding Process

Cooling in injection molding serves several vital purposes:

Solidification of the Product: Once the molten plastic is injected into the mold, cooling is essential to solidify the material into the desired shape. Proper cooling ensures the product maintains its structural integrity and dimensional accuracy.

Cycle Time Reduction: Efficient cooling can significantly reduce the overall cycle time of the molding process. A well-cooled part can be ejected and replaced with the next cycle faster, thereby increasing production efficiency.

Quality Assurance: Uniform cooling plays a crucial role in preventing defects like warping, shrinkage, and residual stress, which can compromise the quality of the product.

Factors Affecting Cooling Time

Several factors influence the cooling time in the injection molding process:

Mold Material and Design: Different mold materials have varying thermal conductivities. For instance, aluminum molds conduct heat faster than steel, potentially reducing cooling time by 20% to 40%.

Thickness of the Molded Part: Thicker parts require longer cooling times. Increasing the wall thickness of a part by 10% can increase cooling time by approximately 20% to 30%.

Cooling System Design: The design of the cooling system, including the placement and size of cooling channels, directly affects the efficiency of heat removal. Optimized cooling channel design can reduce cooling times by 15% to 25%.

Plastic Material Properties: Different plastics have different thermal properties. Materials with high thermal conductivity can reduce cooling times by 10% to 20% compared to those with lower thermal conductivity.

For more detailed information on cooling in injection molding, consider exploring Injection Molding – Wikipedia.

Techniques for Efficient Cooling

Efficient cooling in injection molding not only improves the quality of the final product but also enhances the overall production efficiency. Let’s explore key techniques in mold design optimization and advanced cooling systems.

Optimizing Mold Design for Faster Cooling

Optimizing the design of the mold is crucial for efficient cooling:

Material Selection: Use materials with high thermal conductivity for molds, like beryllium copper or aluminum, which can improve cooling efficiency by up to 50% compared to traditional steel molds.

Cooling Channel Design: Design cooling channels to be closer to the mold surface and evenly distributed. This can reduce cooling time by 20-30%.

Conformal Cooling Channels: Implement conformal cooling channels that follow the shape of the part. This advanced technique can decrease cooling time by up to 40% while maintaining uniform temperature distribution.

Utilizing Advanced Cooling Systems

The integration of advanced cooling systems plays a vital role in reducing cooling times:

Chilled Water Systems: Employing chilled water systems can enhance cooling efficiency. Systems operating at a temperature of 10-15°C can improve cooling rates by 25-35%.

Rapid Thermal Cycling: This involves rapidly heating and cooling the mold surface between cycles. Using systems with a power capacity of 40-60 kW, rapid thermal cycling can reduce cooling time by 15-25%.

Pulsed Cooling Techniques: Pulsed cooling alternates between cooling and minimal flow periods, improving heat transfer efficiency. This can lead to a reduction in cooling time by approximately 10-20%.

For further insights into cooling techniques in injection molding, a visit to Injection Molding Cooling – Wikipedia would be informative.

Material Considerations for Reduced Cooling Time

In injection molding, the choice of material and its properties play a significant role in determining the cooling time. Understanding these aspects can lead to more efficient production processes.

Selecting Materials with Faster Cooling Rates

The thermal properties of the plastic material are crucial for cooling efficiency:

Thermal Conductivity: Materials with higher thermal conductivity cool faster. For example, Polypropylene (PP) with a thermal conductivity of 0.1-0.22 W/mK cools faster than Polyethylene Terephthalate (PET) with a conductivity of 0.15-0.24 W/mK.

Melting Temperature: Plastics with lower melting temperatures typically require less cooling time. ABS, with a melting point of around 200°C, can be cooled faster than materials like Polycarbonate (PC) which have a melting point of approximately 230°C.

Specific Heat Capacity: Materials with lower heat capacity need less time to cool down. For instance, PP has a specific heat capacity of 1.9 J/g°C, making it faster to cool compared to PC, which has a capacity of 1.2 J/g°C.

Impact of Material Thickness on Cooling Efficiency

The thickness of the molded part is a vital factor in cooling efficiency:

Wall Thickness: Thicker walls retain heat longer, increasing cooling time. For instance, increasing the wall thickness from 2mm to 4mm can increase the cooling time by up to 50%.

Design Considerations: Uniform wall thickness and minimal thick sections can enhance cooling efficiency. Techniques like coring out thick areas can reduce the cooling time by 20-30%.

For more comprehensive information about the thermal properties of various plastics, visit Plastics Material Data – Wikipedia.

Process Optimization for Shorter Cooling Times

Optimizing the injection molding process is essential for reducing cooling times and enhancing overall efficiency. The following tables detail how adjusting injection parameters and implementing temperature control strategies can achieve this.

Adjusting Injection Parameters for Efficient Cooling

| Parameter | Adjustment | Impact on Cooling Time | Efficiency Gain |

|---|---|---|---|

| Injection Speed | Increase | Faster filling reduces exposure to heat, decreasing cooling time by up to 15% | Increases productivity |

| Mold Temperature | Lower | Reduces the temperature differential, shortening cooling time by 10-20% | Improves cycle times |

| Hold Pressure | Optimize | Prevents overpacking and excessive heating, potentially reducing cooling time by 5-10% | Enhances part quality |

| Injection Time | Minimize | Less heat input leads to quicker solidification, reducing cooling time by up to 20% | Decreases energy consumption |

Implementing Effective Temperature Control Strategies

| Strategy | Description | Impact on Cooling Time | Cost Implication |

|---|---|---|---|

| Advanced Cooling Channels | Design channels closer to the mold surface for effective heat transfer | Reduces cooling time by 15-25% | Higher initial investment but long-term savings |

| Rapid Cooling Techniques | Use of chilled fluids or gas for rapid temperature reduction | Decreases cooling time by up to 30% | Increased energy usage but improved cycle times |

| Thermal Insulation | Insulate the mold to maintain consistent temperature | Can shorten cooling time by 10-15% | Low-cost implementation with moderate savings |

| Temperature Monitoring Systems | Real-time monitoring and adjustments for optimal cooling | Reduces cooling time variability by 5-10% | Investment in monitoring technology required |

For more in-depth information on optimizing injection molding processes, a visit to Injection Molding Process – Wikipedia is recommended.