To prevent air traps in injection molding, optimize mold design, use appropriate venting solutions, select suitable materials, and fine-tune injection parameters. Regular inspections and data-driven approaches also enhance outcomes.

Factors Contributing to Air Traps

Mold Design

Mold design is a critical factor in the formation of air traps during injection molding. The flow path, venting, and runner system all contribute to how the material fills the mold, potentially causing air to be trapped.

- Flow Path Geometry: Complicated geometries can obstruct smooth flow, causing the material to fold over itself, trapping air.

- Venting: Inadequate venting is often a significant cause of air traps. Proper venting helps to evacuate air from the mold as material fills it.

- Runner and Gate Design: Incorrectly designed runner systems and gate locations can disrupt the natural flow of the material, causing pockets of air to form.

Venting Solutions

The issue of venting in mold design can be tackled by using venting inserts or by cutting small venting channels into the mold itself. It’s essential to consult guidelines and best practices to ensure effective venting.

Material Selection

Different materials have different flow characteristics. Viscosity, melting temperature, and other material properties can either exacerbate or mitigate the likelihood of air traps.

- Viscosity: Materials with higher viscosity are more likely to trap air as they fill the mold.

- Melting Temperature: Materials that require higher melting temperatures may be more prone to air traps due to increased viscosity at these temperatures.

Pre-treatment Methods

It may be useful to pre-dry or condition the material to minimize moisture content, which can contribute to air traps. This is especially true for hygroscopic materials.

Injection Speed

The speed at which the material is injected into the mold plays a vital role in air trap formation.

- High-Speed Injection: Faster injection rates can push air into the mold cavity before it has a chance to escape.

- Low-Speed Injection: Slower injection rates may allow air to escape but might cause other issues like incomplete filling.

Optimizing Injection Parameters

Experimenting with different injection speeds and pressures can help to find the optimal settings for minimizing air traps. Utilize Design of Experiments (DOE) methodology to identify the ideal parameters.

Temperature Settings

Both mold temperature and material temperature can contribute to air traps.

- Mold Temperature: A colder mold can cause the material to solidify before air has escaped, trapping it inside.

- Material Temperature: If the material is too hot, it can become more viscous, making it harder for air to escape.

Best Temperature Practices

Maintaining a consistent temperature profile throughout the molding process is crucial. This involves monitoring the temperature of the machine barrel, the mold, and even the ambient temperature of the manufacturing environment.

Preventative Methods

Venting Solutions

Proper venting plays a critical role in preventing air traps. It allows air and other gases to escape from the mold cavity during the injection process.

- Vent Placement: Strategically place vents in areas where air is likely to be trapped.

- Vent Size: Choose appropriate vent sizes. Smaller vents can clog quickly, whereas larger vents might cause material leakage.

- Vent Material: Use materials for the vent that are durable and resistant to the molding material to avoid any unwanted reactions.

Advanced Venting Technologies

Incorporate advanced venting systems like vacuum vents, which actively remove air from the mold cavity. These are especially useful in complex geometries where traditional venting solutions might not be effective.

Mold Design Adjustments

Modifying the mold design can be an effective method of eliminating air traps.

- Runner and Gate Redesign: Optimize the shape and location of runners and gates to facilitate a more streamlined flow of material.

- Mold Cavity Modifications: Rework the mold cavities to eliminate any undercuts or sharp corners where air might be trapped.

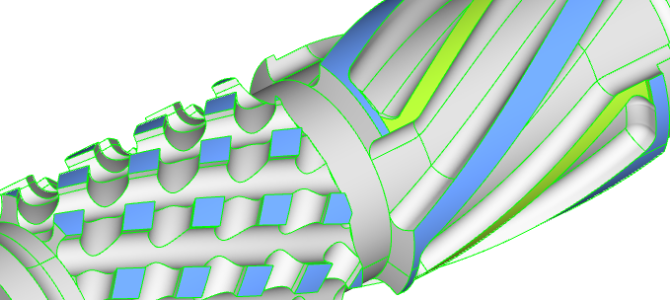

Simulation Software

Use CAE (Computer-Aided Engineering) simulation software to predict the flow patterns and identify potential areas for air trap formation before finalizing the mold design.

Material Pre-Treatment

Preparing the material properly can help minimize the likelihood of air traps.

- Drying: Dry hygroscopic materials to reduce moisture, which can lead to air traps.

- Blending: Blend additives or fillers evenly to ensure consistent material properties.

Conditioning Protocols

Implement strict material conditioning protocols that outline the temperature and duration for which materials need to be prepared before the injection process.

Optimizing Injection Parameters

The way the material is injected into the mold can also impact the formation of air traps.

- Injection Speed: Experiment with different injection speeds to find the optimal rate that minimizes air traps.

- Pressure Settings: Adjust the injection pressure based on the material’s viscosity and the mold’s complexity.

Process Monitoring

Use real-time monitoring systems to track parameters like injection speed and pressure. Refer to SCADA systems for advanced process monitoring that can help in making real-time adjustments.

Diagnostic Techniques

Flow Simulation Software

Flow simulation software is an invaluable tool for diagnosing potential issues that can lead to air traps in injection molding.

- Simulation Accuracy: Choose software with high simulation accuracy to model the flow of material through the mold.

- Real-Time Monitoring: Some advanced software offers real-time simulation capabilities that can be integrated into the injection molding machine control systems.

Software Recommendations

For those unfamiliar with flow simulation software, some industry-leading options include Autodesk Moldflow and ANSYS Polyflow.

Short-Shot Testing

Short-shot testing involves injecting a reduced amount of material into the mold to deliberately stop the shot before the mold fully fills. This method reveals where the material front advances and identifies locations prone to air traps.

- Visual Inspection: Examine the partial fill for signs of air entrapment.

- Material Volume: Adjust the amount of material for the test shot to understand how different volumes influence air traps.

Additional Short-Shot Considerations

When conducting short-shot testing, it’s essential to consider the impact of injection speed and pressure on the results to get a more comprehensive understanding of how air traps form.

Pressure Drop Analysis

Pressure drop analysis is a method that measures the pressure change as the material flows through the mold.

- Pressure Sensors: Use pressure sensors located at strategic points within the mold to gather data.

- Data Analysis: Examine the collected data to identify any sudden drops in pressure, which can be indicative of air traps.

Advanced Analytical Tools

Employ advanced tools like Computational Fluid Dynamics (CFD) to analyze the pressure drop data in combination with flow simulations for a more accurate diagnosis.

Best Practices

Routine Inspection

Consistent and thorough inspections of both the injection molding machine and the mold itself are crucial for preventing air traps.

- Daily Checks: Conduct daily checks for any visible defects in the mold and machine.

- Maintenance Schedule: Stick to a maintenance schedule to ensure all parts are working as they should.

Periodic Audits

Carry out periodic audits of the entire injection molding process. Use these audits to update maintenance schedules and checklists.

Staff Training

An educated and trained staff is essential for identifying and preventing the formation of air traps.

- Onboarding Training: Include a section on preventing air traps in your onboarding training for new staff.

- Continuous Education: Provide ongoing training programs that cover new technologies and methods for preventing air traps.

Specialized Training Programs

Institute specialized training programs that focus on understanding the material science and engineering aspects that contribute to air traps. This can include real-world examples and case studies for a more practical understanding.

Data-Driven Approaches

Utilizing data analytics can offer valuable insights into the factors leading to air traps.

- Data Collection: Collect data on injection speed, pressure, material temperature, and other relevant factors.

- Data Analysis: Use analytical tools to identify patterns and correlations that can lead to the formation of air traps.

Advanced Analytics and Machine Learning

Consider implementing advanced analytics tools and machine learning algorithms to predict the likelihood of air trap formation based on the collected data. These predictive models can provide real-time feedback, allowing for immediate adjustments to the injection molding process.