Automotive plastic injection molding

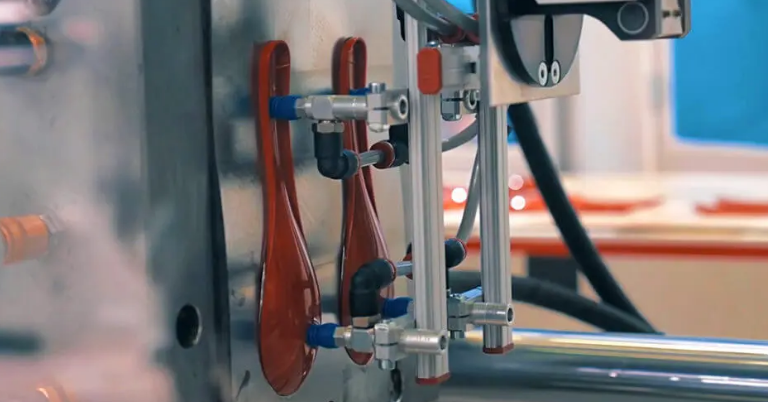

Automotive plastic injection molding is a process for creating durable, precision parts used in vehicle manufacturing, like dashboards and bumpers. Basics of Automotive Plastic Injection Molding Automotive plastic injection molding is a pivotal process in the manufacturing of a vast array of vehicle components. This method combines efficiency, precision, and versatility, making it a cornerstone …