Maintenance Best Practices for Injection Molding Machines

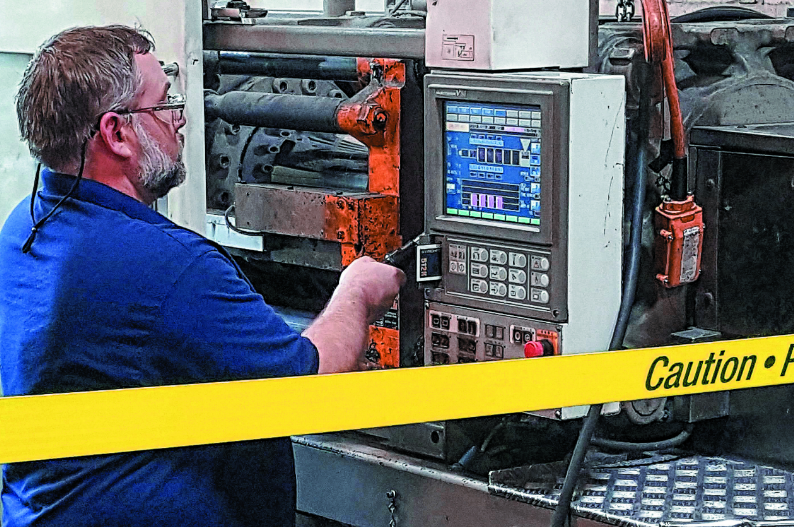

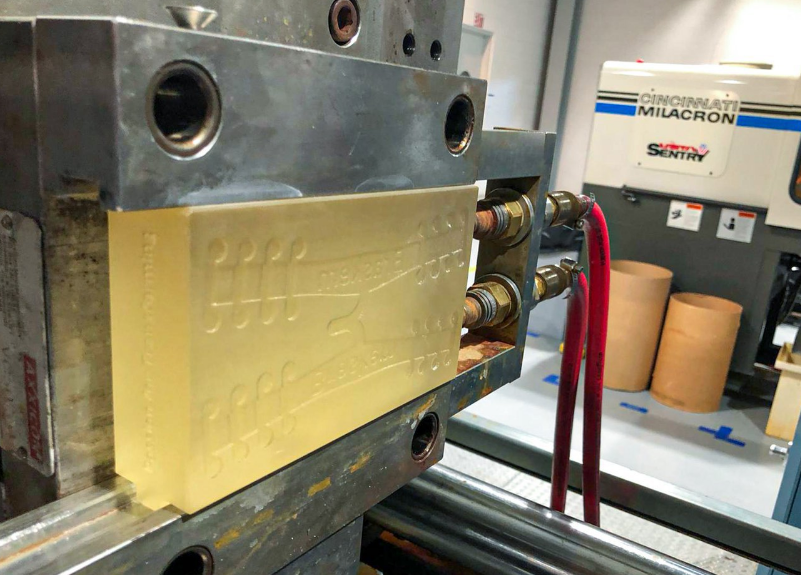

Effective maintenance of injection molding machines includes regular inspections, preventive maintenance, accurate record-keeping, and the use of advanced technologies for predictive maintenance. Routine Maintenance Procedures for Injection Molding Machines Regular maintenance is crucial for ensuring the longevity and efficient operation of injection molding machines. Key routine procedures include conducting daily inspections and adhering to a …

Maintenance Best Practices for Injection Molding Machines Read More »