What is the difference between a side and B side injection molding?

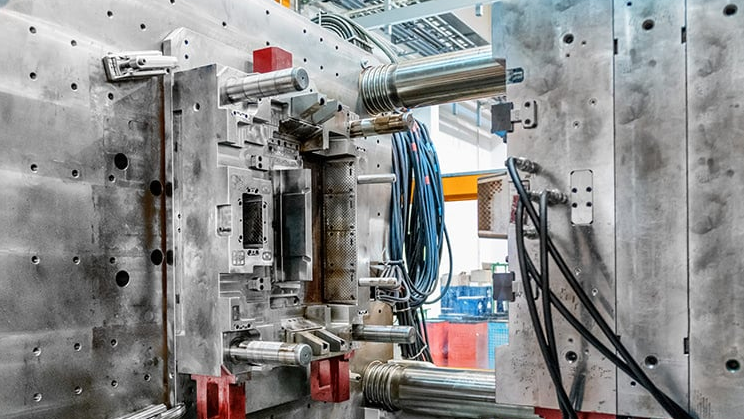

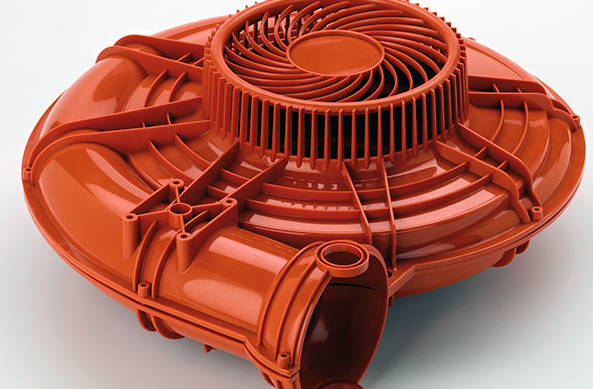

The difference lies in their focus: A Side molding emphasizes surface aesthetics, while B Side molding concentrates on structural features. Overview of Injection Molding Injection molding is a widely used manufacturing process for producing parts from both thermoplastic and thermosetting plastic materials. The technique involves feeding plastic material into a heated barrel, mixing it, and …

What is the difference between a side and B side injection molding? Read More »