What are the size limitations of injection molding

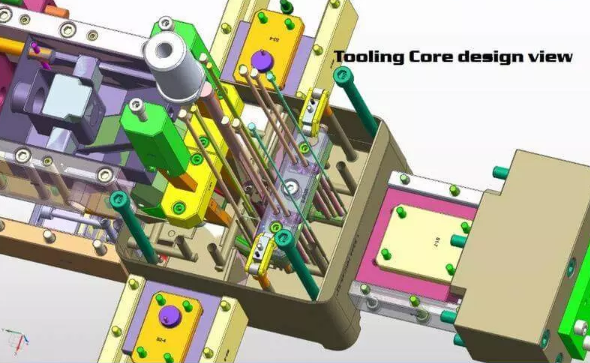

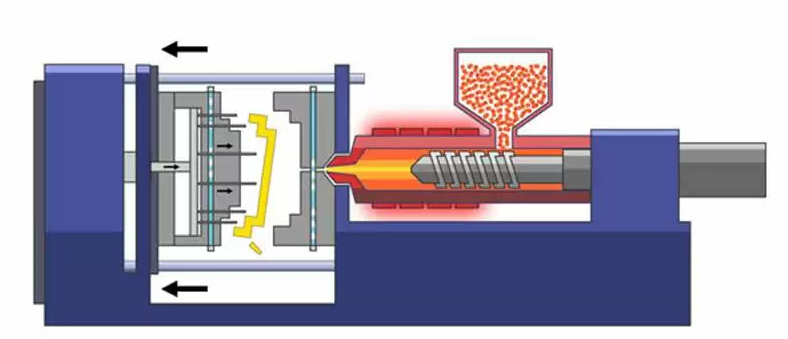

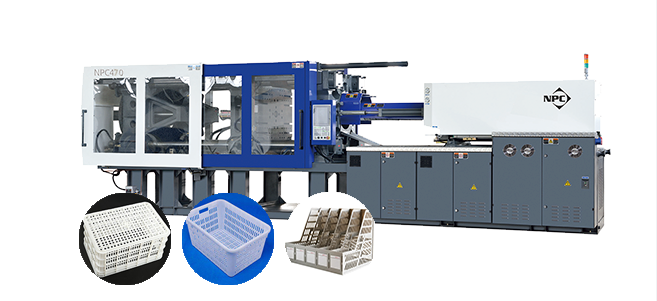

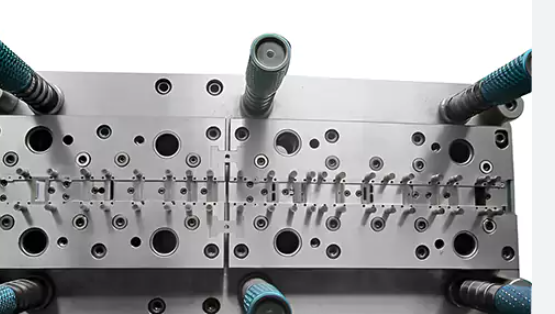

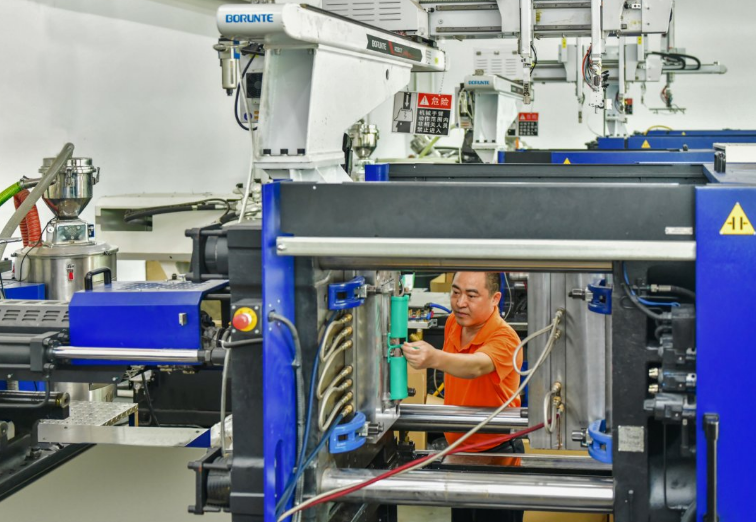

The size limitations of injection molding depend on factors like machine tonnage, mold design, and material, typically ranging from small parts to larger, complex components. Fundamentals of Size Limitations in Injection Molding Physical Constraints of Injection Molding Machines Injection molding machines come with inherent physical limitations that directly impact the size of parts they can …

What are the size limitations of injection molding Read More »