Which products are made by extrusion molding

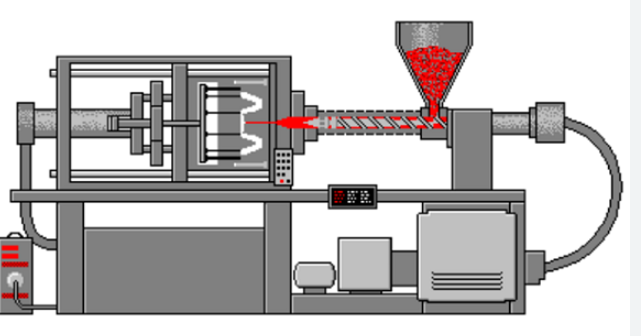

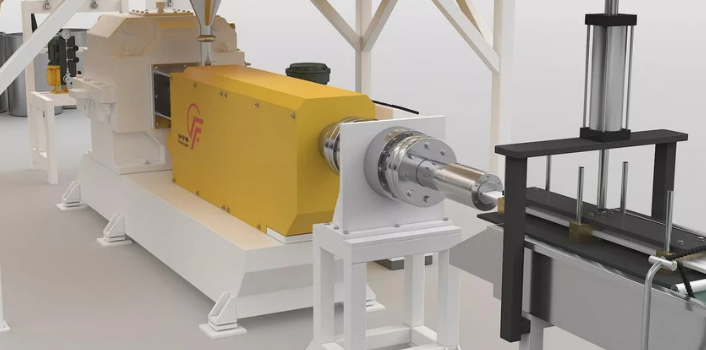

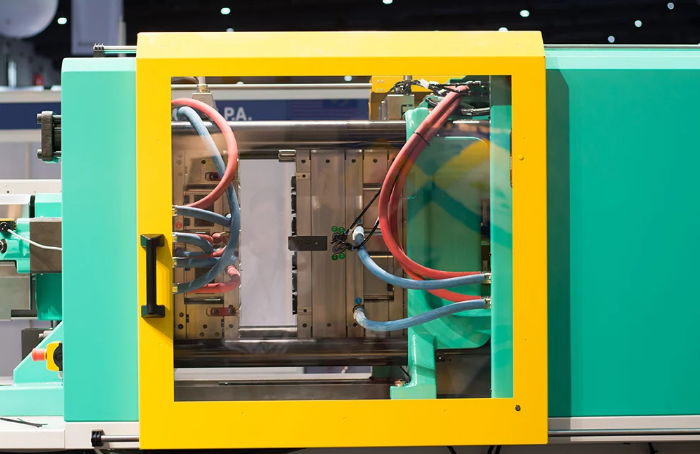

Extrusion molding is used to make products such as pipes, tubes, profiles, sheets, and some types of packaging materials like plastic films and sheets. Overview of Extrusion Molding Process Definition and Basic Principles Extrusion molding is a manufacturing technique where a material, typically a thermoplastic or metal, is pushed through a die to create objects …