What is the impact of injection speed on injection molding

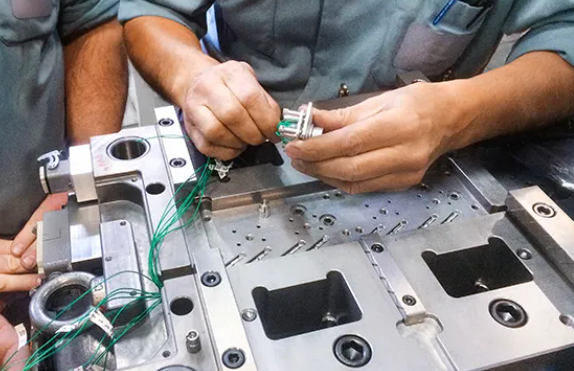

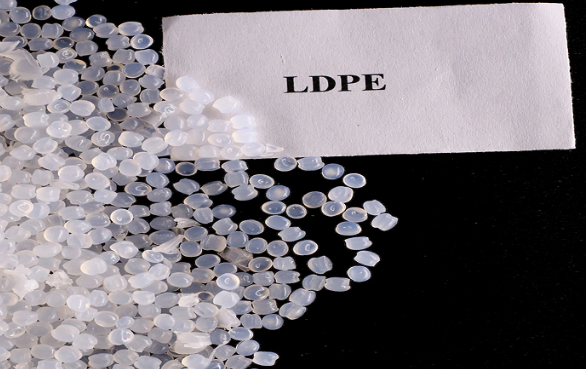

Injection speed affects material flow, part quality, surface finish, and the overall efficiency of the molding process. Fundamentals of Injection Speed in Molding Definition and Measurement of Injection Speed Injection speed is crucial in molding. It determines the rate at which plastic fills the mold. Measured in millimeters per second (mm/s), speeds typically range from …

What is the impact of injection speed on injection molding Read More »