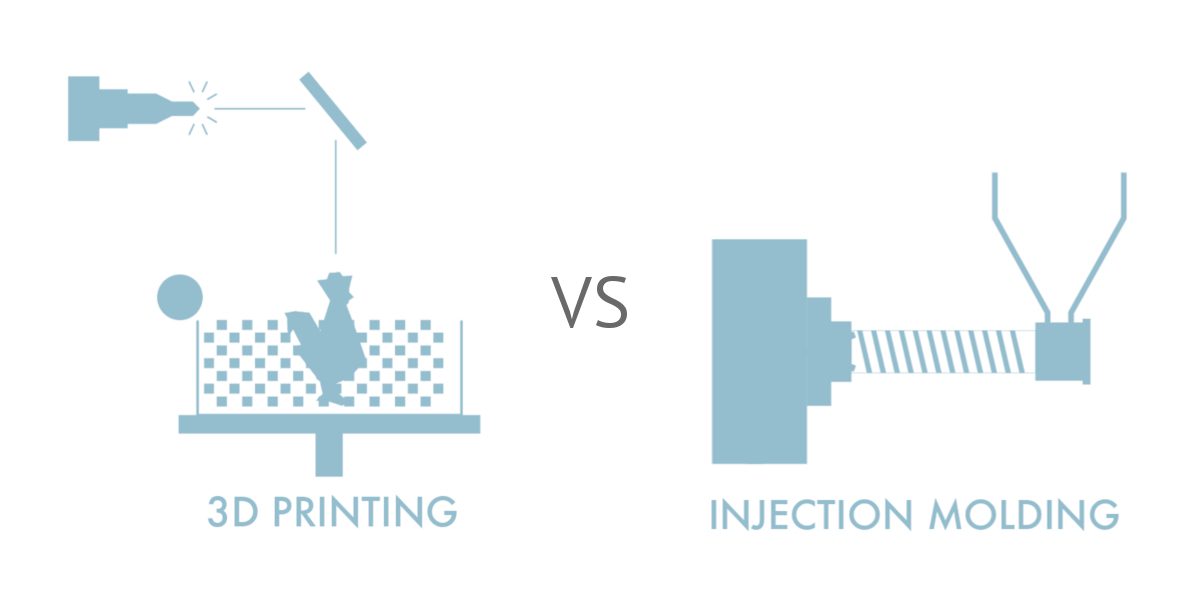

What is the Difference Between Extruder and Injection Molding Machine?

The primary difference between an extruder and an injection molding machine is their function: an extruder continuously pushes material through a die to create long, uniform shapes, while an injection molding machine produces discrete, often complex parts by injecting molten material into a mold. Basic Principles Working Principle of an Extruder The core function of …

What is the Difference Between Extruder and Injection Molding Machine? Read More »