What is the Minimum Draft Angle for Vacuum Forming?

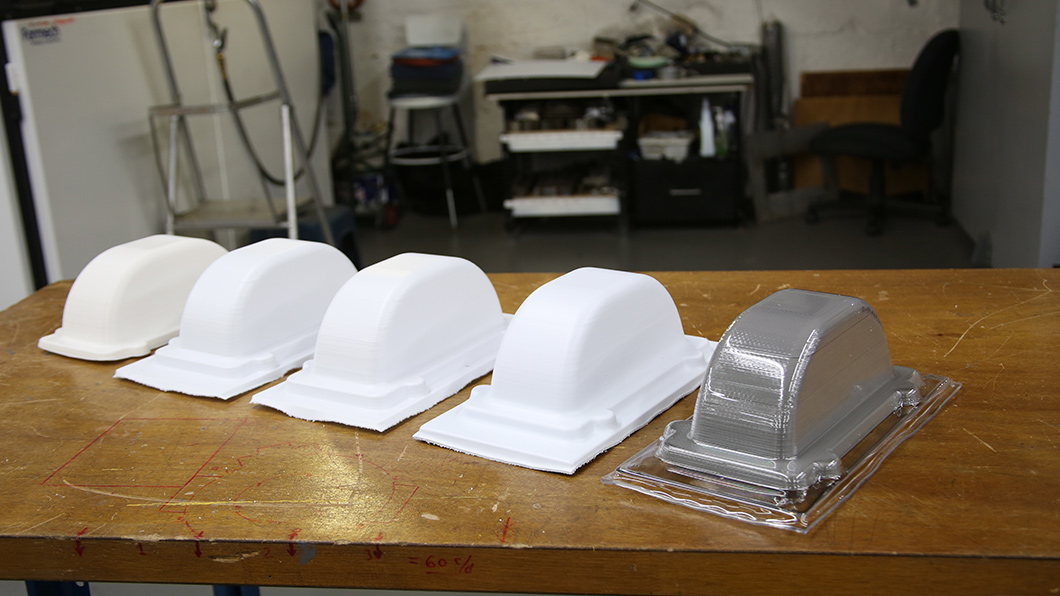

The minimum draft angle for vacuum forming typically ranges from 1 to 3 degrees, ensuring easy demolding and quality production. Understanding Draft Angles Concept of Draft Angle in Vacuum Forming Draft angle, fundamental in vacuum forming, refers to the slight tilt or angle given to the sidewalls of a mold to facilitate the easier ejection …

What is the Minimum Draft Angle for Vacuum Forming? Read More »