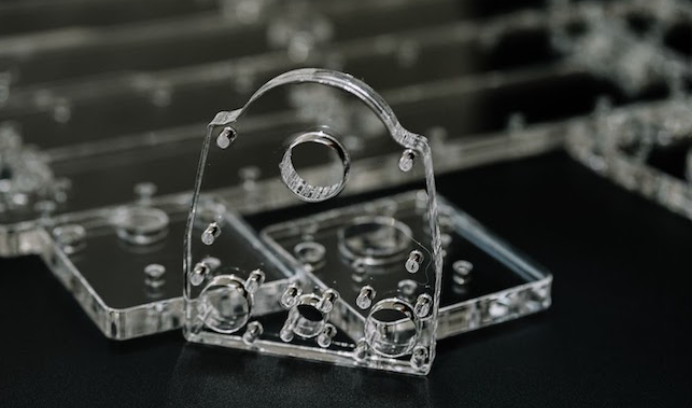

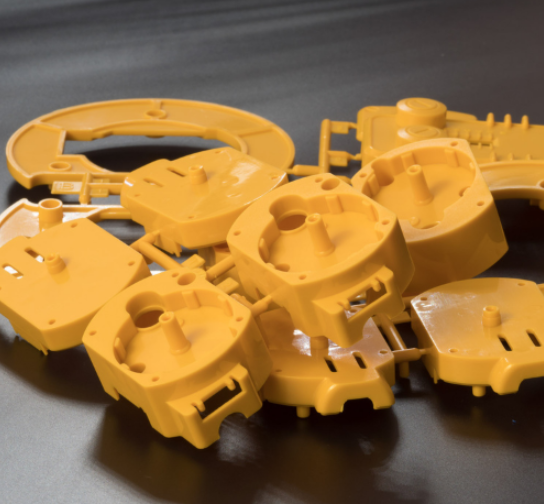

Can injection molded plastic be recycled?

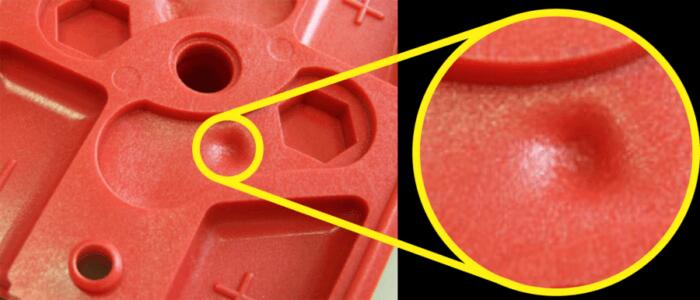

Yes, injection molded plastic can be recycled, but the process can be complex due to contamination and material diversity. The Importance of Recycling Injection Molded Plastic Recycling injection molded plastic is critical due to its wide application across various sectors and its potential to promote environmental sustainability and economic growth. Environmental Impact of Plastic Waste …