Which country has the cheapest injection molding services?

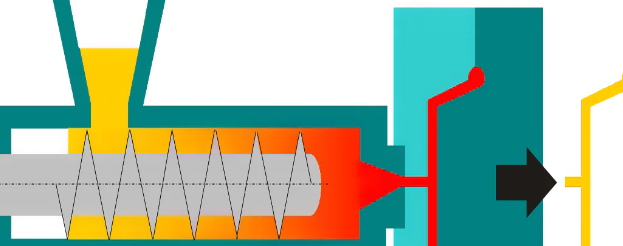

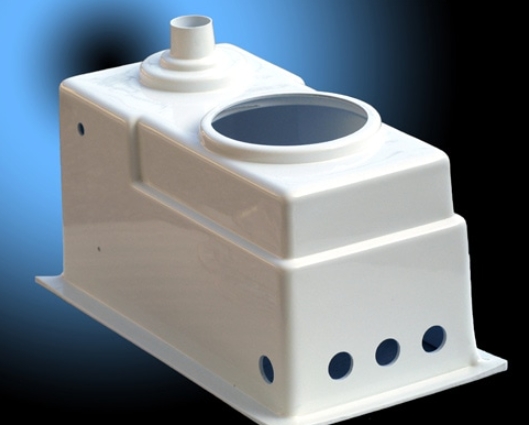

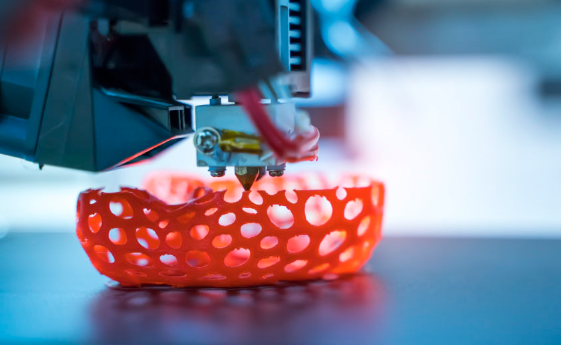

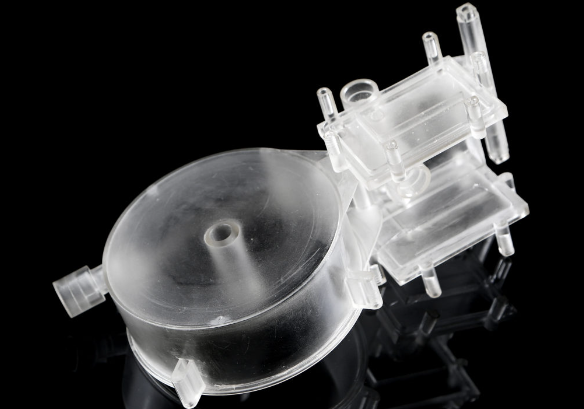

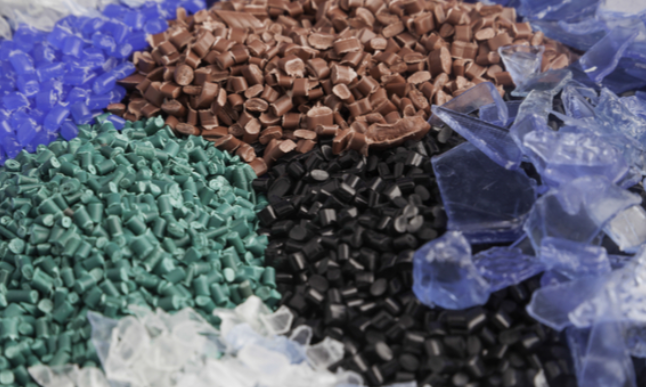

China offers the most affordable injection molding services due to low labor costs and efficient production processes. Introduction to Injection Molding Services Globally Injection molding is a widely used manufacturing process for producing plastic parts by injecting molten material into a mold. This process is crucial for mass-producing high volumes of identical parts with high …

Which country has the cheapest injection molding services? Read More »