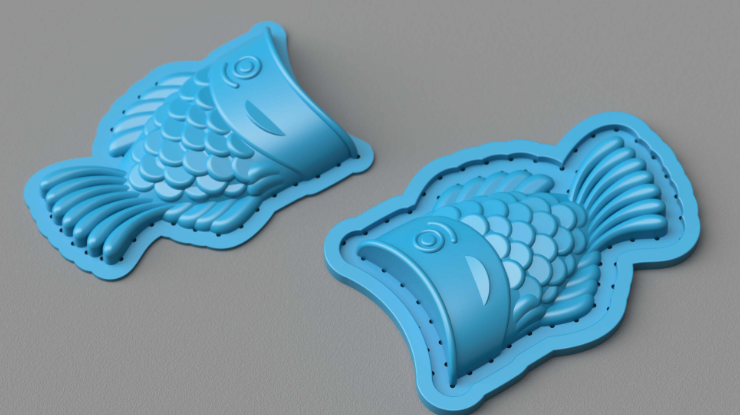

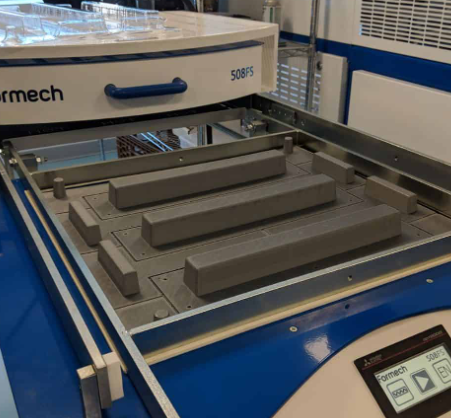

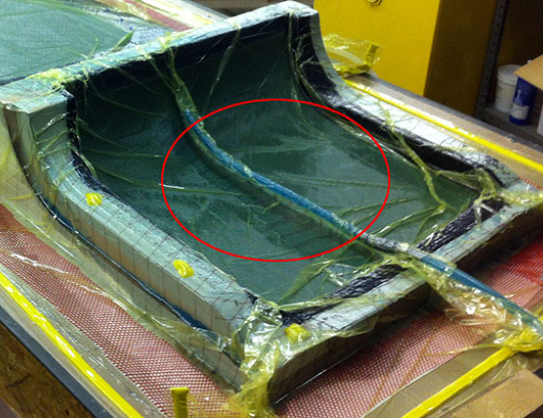

What is the minimum radius for vacuum forming?

The minimum radius in vacuum forming depends on material thickness, type, and mold design, typically ranging from 3 to 50 mm. Design Parameters in Vacuum Forming Impact of Material Selection on Minimum Radius Choosing the right material is crucial for achieving the desired minimum radius in vacuum forming. Different materials have varying degrees of flexibility …