How expensive is injection molding

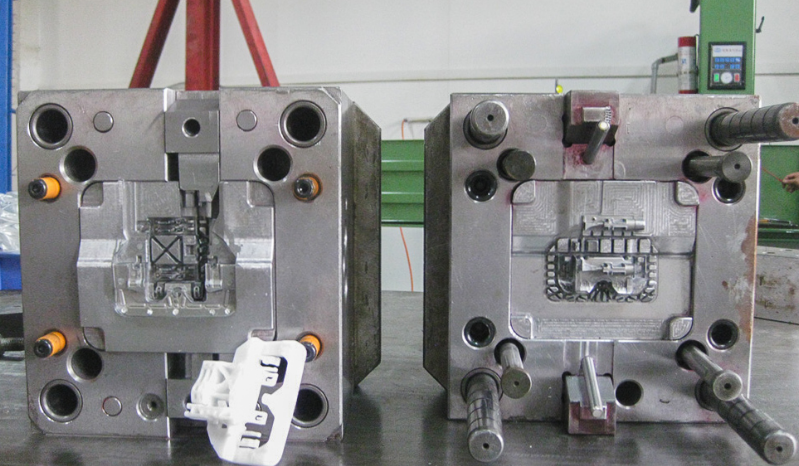

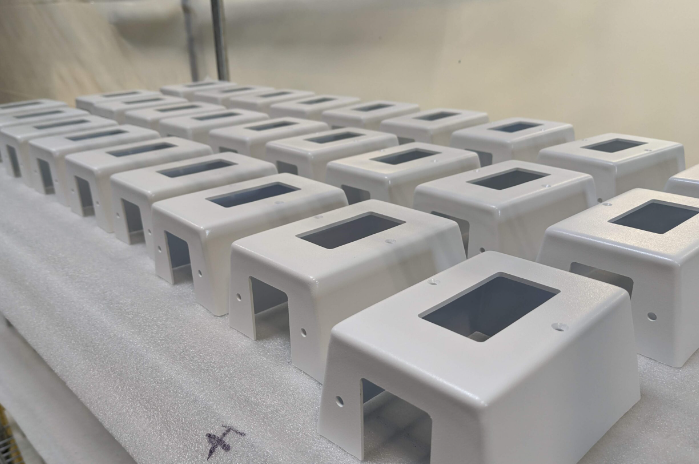

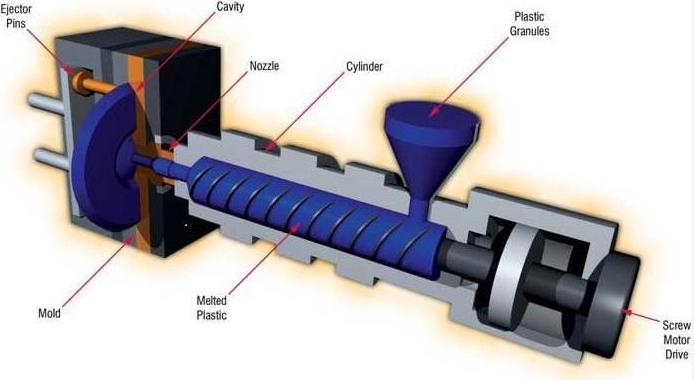

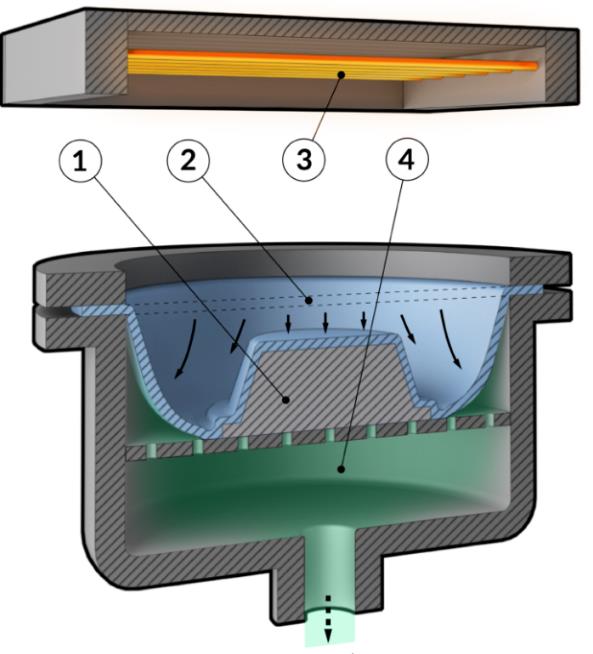

Injection molding costs depend on factors like complexity, materials, and volume. Generally, it’s cost-effective for high production runs. Overview of Injection Molding Costs Understanding the Basic Cost Structure Injection molding costs are multifaceted and can be broken down into several key components: Mold Cost: The initial creation of the mold is often the most significant …