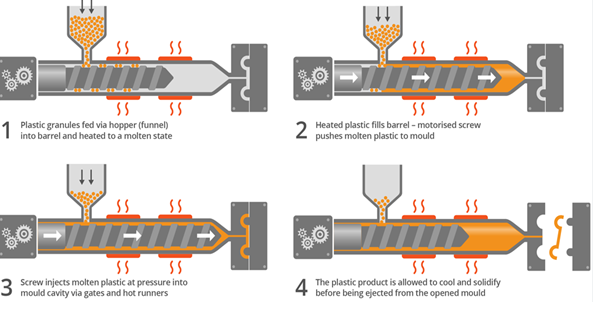

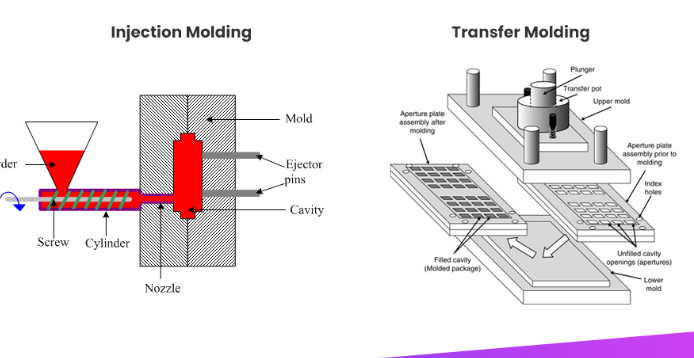

Why do companies use injection molding?

Companies use injection molding for its cost-efficiency, versatility in materials, precision, and scalability for mass production. Benefits of Injection Molding for Businesses Injection molding offers significant advantages for businesses, streamlining manufacturing processes and enhancing product quality. This method stands out for its cost-effectiveness, material versatility, and scalability. Cost-Effectiveness and Efficiency Businesses often seek cost-effective solutions …