Yes, injection molding can create complex shapes, aided by advanced technologies and mold designs.

Capabilities of Injection Molding in Complex Shape Production

Injection molding, known for its versatility, can create parts with intricate designs. However, achieving complex shapes depends on understanding the technical limitations and material properties involved.

Technical Limits in Shape Complexity

Mold Design Limitations:

Undercuts and Sharp Corners: These features often necessitate complex mold designs. For example, a mold with multiple undercuts might increase the tooling cost by 20-30%.

Cooling and Warping: Uneven cooling in complex shapes can lead to warping. Parts with non-uniform wall thickness may experience a 15-20% increase in defective rates due to warping.

Efficiency and Cost:

Cycle Time Increase: Complex designs can extend cycle times by 40-50% compared to simpler shapes.

Tooling Cost: The cost of a mold can range from $3,000 for basic designs to over $100,000 for intricate molds with multiple moving parts.

Material Considerations for Complex Shapes

Ideal Material Properties:

Thermoplastics: ABS and Polycarbonate are preferred for complex shapes, as they offer a good balance of flowability and strength.

Material Flexibility: Silicone can be 30-40% more expensive than rigid materials like nylon but offers greater flexibility.

Performance and Cost Trade-offs:

High-Performance Materials: Using PEEK, known for its strength, can increase material costs by up to 50% compared to standard plastics.

Thermal Stability: Materials with stable thermal properties, essential for maintaining shape integrity, may add 20-25% to the material cost.

Explore Injection Molding and Thermoplastics on Wikipedia for more detailed information.

Advanced Techniques in Injection Molding for Complex Shapes

Injection molding has evolved to include advanced techniques like overmolding, insert molding, and micro injection molding. These methods enhance the capability to produce complex and detailed components.

Overmolding and Insert Molding

Overmolding Process:

Procedure: Involves molding a second material over a previously molded part.

Materials: Typically uses softer plastics like TPE (Thermoplastic Elastomers) over a rigid base such as ABS.

Cost Impact: Increases production cost by 20-30% due to additional material and processing steps.

Application: Ideal for creating parts with soft grips or multiple colors.

Insert Molding Details:

Process: Involves embedding a pre-made part (metal or plastic) into the plastic mold.

Material Cost: The cost can increase by 15-25% depending on the insert material.

Efficiency: Reduces assembly time and increases part strength, often offsetting the added cost.

Use Cases: Commonly used for integrating metal components into plastic parts.

Micro Injection Molding for Detailed Features

Process Specifications:

Capabilities: Specializes in producing extremely small and precise components.

Part Size: Can produce parts weighing less than a gram, with features as small as 0.1mm.

Machinery Cost: Micro molding machines are typically 30-40% more expensive than standard machines.

Material and Quality Considerations:

Material Selection: Requires high-flow materials to accurately fill tiny cavities.

Quality Control: Ensures high precision, but increases production time and costs due to stringent quality checks.

For further reading, explore the Wikipedia pages on Injection Molding, Overmolding, and Micro Injection Molding.

Design Principles for Complex Shapes in Injection Molding

Mastering design principles is crucial for successfully producing complex shapes in injection molding. These principles focus on enhancing moldability and ensuring structural integrity, even in the most intricate designs.

Optimizing Design for Moldability

Draft Angles and Wall Thickness:

Draft Angles: Essential for easy part ejection, recommended angles range from 1° to 3°.

Uniform Wall Thickness: Ideally, wall thickness should be consistent, around 2-3 mm for most materials, to avoid defects like sink marks.

Mold Flow Analysis:

Purpose: Identifies potential issues like air traps or insufficient material flow.

Impact on Production: Using mold flow analysis software can increase pre-production costs by around 10-15%, but significantly reduces the risk of costly mold revisions.

Balancing Complexity with Structural Integrity

Design Strategies:

Ribs and Gussets: Use of ribs and gussets for reinforcement, keeping rib thickness at about 60% of the adjoining wall to prevent sinking.

Gate and Runner Design: Proper gate and runner design ensures optimal material flow, which is crucial for maintaining the integrity of complex shapes.

Material Considerations:

Material Selection: High-flow materials are preferred for intricate designs. For example, Nylon has a flow rate of 200-300 cm³/10 min, making it suitable for complex shapes.

Impact of Material on Cost: Selecting specialized materials can increase the material cost by up to 20-30%.

For more comprehensive information, the Wikipedia pages on Injection Molding and Mold Flow Analysis offer valuable insights into these topics.

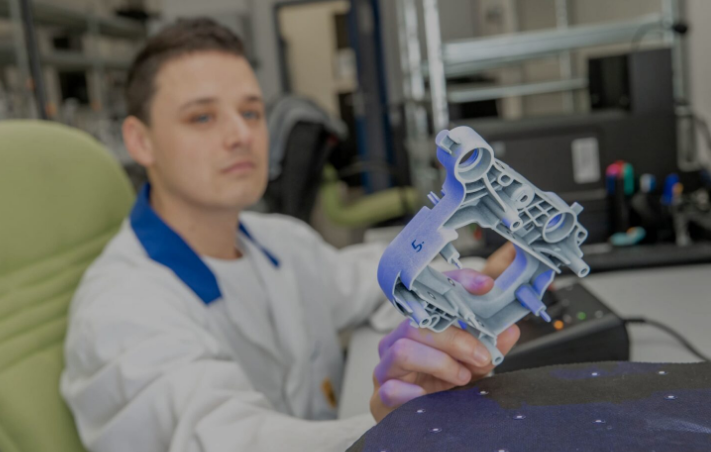

Case Studies: Successes in Complex Shape Fabrication

Injection molding has played a pivotal role in manufacturing complex shapes, particularly in the automotive and medical industries. The following table highlights specific examples from these sectors, detailing the efficiencies and challenges involved.

Automotive Industry Applications

| Component | Material Used | Complexity | Benefits | Cost & Efficiency |

|---|---|---|---|---|

| Dashboard | ABS Plastic | High (intricate shapes and textures) | Durability and Aesthetic Appeal | Moderate cost; ABS costs about $1.50/kg, production cycle 30-45 sec/part |

| Air Vents | Polycarbonate/ABS Blend | Medium (complex airflow paths) | Heat Resistance and Strength | Slightly higher cost due to material blend; cycle time approx. 20-30 sec/part |

Medical Device Manufacturing Examples

| Device | Material Used | Complexity | Benefits | Cost & Efficiency |

|---|---|---|---|---|

| Surgical Tools | Medical-grade Stainless Steel (MIM Process) | Very High (fine details) | Precision and Sterilization Compatibility | High cost due to material and precision requirements; cycle time 1-2 min/part |

| Implantable Devices | PEEK | High (biocompatibility requirements) | Biocompatibility and Durability | Very high cost (PEEK costs about $90/kg); cycle time varies based on complexity |

These case studies demonstrate the versatility of injection molding in producing parts with complex geometries and the critical role of material selection in balancing cost, efficiency, and functionality.

For more detailed insights into these applications, explore the Wikipedia pages on Injection Molding, Automotive Industry, and Medical Device manufacturing.