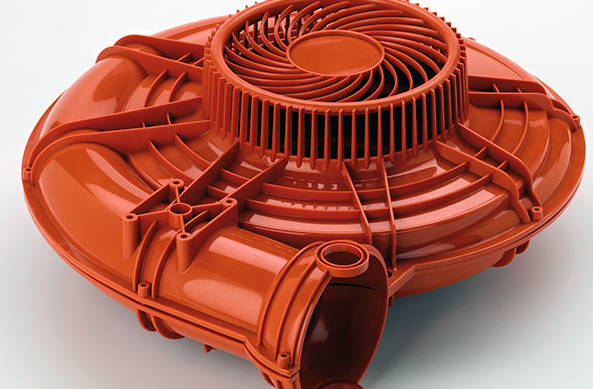

Yes, injection molding is suitable for complex part geometries, thanks to precise tooling and high-pressure molding capabilities. It’s ideal for intricate designs.

Understanding Complex Geometries in Injection Molding

Definition of Complex Geometries

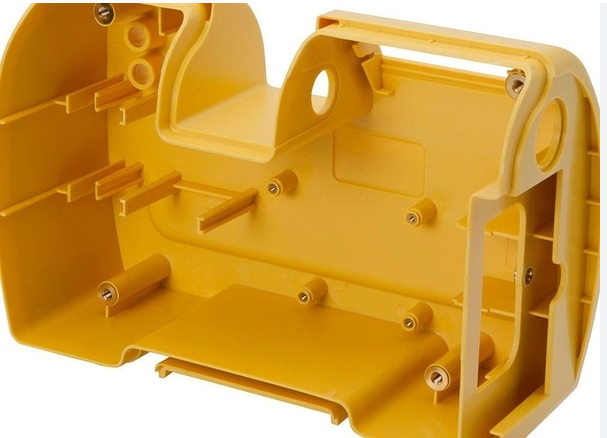

Complex geometries in injection molding are characterized by intricate details and sophisticated shapes. These include undercuts, thin walls as fine as 0.5mm, and tight tolerances often required to be within ±0.005 inches. Complex geometries challenge standard molding techniques, necessitating advanced technologies and precise control over the molding process.

Importance of Geometry in Mold Design

The geometry of a mold is a critical factor in determining the success of an injection molding project. Accurate mold design ensures the quality and functionality of the final product. Precise dimensions are vital; for instance, gear molds must have exact tooth profiles, often requiring tolerances within 0.001 inches. Furthermore, the design must accommodate the flow of molten plastic, considering factors like injection speed and pressure, which can range from 10,000 to 30,000 psi, to prevent defects like warping or incomplete filling.

It involves balancing technical precision with cost-effectiveness and material properties. The evolving landscape of Injection Molding technology plays a crucial role in expanding the possibilities for creating intricate and high-quality parts.

Capabilities of Injection Molding for Complex Shapes

Technical Limitations and Possibilities

Injection molding has greatly advanced, allowing for complex shapes. Yet, technical limits remain. High precision in molding complex shapes requires machines that can sustain up to 30,000 psi pressure. Also, molding equipment must be high-resolution to replicate details as small as 0.0005 inches.

For larger complex parts, challenges increase. Standard machines handle parts up to 48 inches, but larger designs might need specialized equipment. This raises costs and slows production, as larger molds need longer cooling times, extending cycles to minutes per part.

Material Considerations for Complex Molds

Selecting the right materials for both mold and product is vital. High-performance plastics like PEEK or Ultem, used for complex parts, offer strength and shape stability under stress. However, these materials can be expensive, sometimes up to $10 per pound, affecting budgets.

Hardened steel is often chosen for molds due to its durability, crucial for large production runs. For prototypes or small batches, aluminum provides a cost-effective option, though it’s less durable.

The field is continually evolving, with new advancements in materials and technology. For further details, refer to Injection Molding on Wikipedia.

Design Strategies for Complex Injection Molding

Advanced Mold Design Techniques

| Technique | Description | Benefits | Considerations |

|---|---|---|---|

| Conformal Cooling Channels | Custom cooling channels that follow the mold’s contour. | Reduces cooling time by up to 50%, improves product quality. | Higher initial design and production cost. |

| High-Precision Machining | Utilizing state-of-the-art CNC machines for mold making. | Achieves tolerances as tight as ±0.0005 inches. | Requires significant investment in equipment. |

| Modular Mold Design | Creating molds in segments for easy modification. | Enhances flexibility, reduces downtime for changes. | Complex planning required, potential for misalignment. |

Utilizing CAD/CAM Software for Precision

| Software Aspect | Description | Impact | Example Software |

|---|---|---|---|

| 3D Modeling | Creating detailed digital models of the mold. | Ensures precise dimensions, allows for virtual testing. | Autodesk Fusion 360, SolidWorks |

| Simulation | Running virtual tests for mold filling, cooling, etc. | Identifies potential defects, optimizes process parameters. | Moldflow, Cimatron |

| Integration with Machining | Direct link from design to CNC machines. | Reduces errors, streamlines production process. | Mastercam, CAMWorks |

The continuous advancements in these areas are pivotal, as detailed on the Injection Molding Wikipedia page, for pushing the boundaries of what can be achieved in this field.

Process Optimization for Complex Geometries

Enhancing Mold Flow Analysis

Mold flow analysis is crucial for predicting and optimizing how plastic flows within a mold, especially for complex geometries. Advanced software tools enable precise simulation of the injection process, revealing potential issues like air traps or insufficient filling before production begins. By adjusting variables like injection speed and pressure, manufacturers can anticipate and mitigate these issues. For instance, optimal injection speeds can vary significantly, often between 30 to 100 cm³/s, depending on the complexity of the part and the type of plastic used.

Customizing Injection Parameters for Complexity

Customizing injection parameters is essential for manufacturing complex geometries. Key parameters include injection pressure, holding pressure, and cooling time, each tailored to the specific requirements of the part. Injection pressures can range widely, from as low as 500 psi for simple geometries to over 20,000 psi for complex designs. Similarly, cooling times may need adjustment, from a few seconds for thin-walled parts to several minutes for thicker or more intricate designs. This customization ensures the highest quality of the final product while optimizing cycle time and minimizing defects.

For more insights into this process, refer to Injection Molding on Wikipedia.