Yes, plastic bottles are typically produced using the injection molding process, where molten plastic is injected into a mold cavity.

Basics of Injection Molding

Injection molding is a popular manufacturing process predominantly utilized in producing parts by injecting molten material into a mold. Here, we’ll specifically delve into the details of plastic injection molding.

What is Injection Molding?

Components of an Injection Molding Machine

- Feed Hopper: This is where the plastic pellets are loaded. It’s usually a large, open funnel-shaped section situated atop the machine.

- Heating Barrel: The plastic pellets from the hopper are heated here until they reach a molten state. Depending on the material and specifications, the average temperature can range from 200°C to 300°C.

- Screw: Situated within the barrel, this component is responsible for mixing and pushing the molten plastic through the machine. It moves in a rotational and axial direction.

- Nozzle: The molten plastic exits the barrel through this component, which ensures the material is smoothly directed into the mold.

- Clamping Unit: This holds the mold halves together during the injection process. Depending on the machine’s size, the clamping force can range between 5 to 6,000 tons.

- Mold: This is where the actual shaping of the plastic occurs. It consists of two halves that, when closed, form the shape of the desired part.

Advantages and Disadvantages of Injection Molding

Advantages:

- High Production Speed: Once set up, injection molding machines can produce thousands of parts in a short span, often within minutes.

- Precision: The parts produced through this method are highly consistent and accurate, with tolerances as tight as 0.005 inches.

- Low Labor Costs: Despite the initial setup being labor-intensive, once in operation, the machine requires minimal human intervention, resulting in reduced labor costs.

- Material and Color Flexibility: The process allows for a wide range of plastic materials and colors to be used, leading to diverse product outcomes.

Disadvantages:

- High Initial Costs: The initial investment for an injection molding machine and the mold can be substantial, ranging from $50,000 to $500,000, depending on the machine’s specifications and mold complexity.

- Limitations in Part Design: Certain geometric complexities can be challenging to achieve with this method.

- Maintenance Costs: Regular maintenance is essential to ensure the machine’s longevity, which can lead to added expenses over time.

- Environmental Concerns: The use of plastics and the waste generated can raise environmental concerns, especially when not managed sustainably.

Process of Making Plastic Bottles

The creation of plastic bottles involves a multi-step process. These bottles, often used for beverages, personal care products, and many other consumer goods, have become an integral part of our daily lives. Two primary stages dominate their production: preform manufacturing and the bottle blowing process.

Preform Manufacturing

- Material Selection: The primary material for most plastic bottles is PET because of its strength, clarity, and versatility. A 1000kg batch of PET granules can cost around $1,200 to $1,600.

- Molding: The molten PET is then injected into preform molds, giving it an initial shape. This shape resembles a test tube, with the screw top that’s recognizable as the bottle cap thread. The cooling time for the preform can vary, but it’s usually in the range of 20 to 30 seconds.

- Cooling: Once shaped, the preforms are cooled rapidly to retain their form and prepare for the next stage.

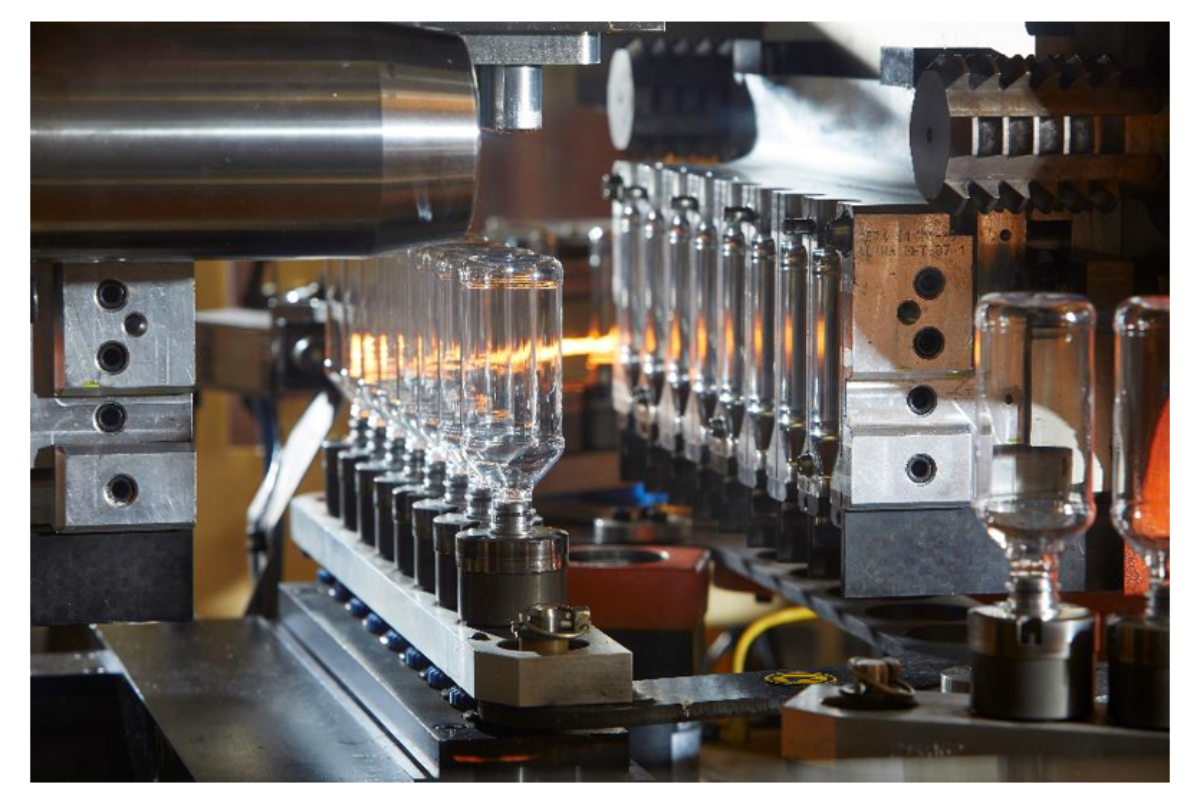

Bottle Blowing Process

- Heating: The preforms are first heated to a specified temperature range, typically around 90°C to 100°C, making them pliable and ready for reshaping.

- Blowing: The heated preform is then placed in a bottle mold, and high-pressure air, around 25 to 40 bar, is blown into it. This air forces the preform to expand and take the shape of the mold, thereby creating the bottle.

- Cooling: Once the bottle shape is achieved, the mold cools the plastic rapidly, usually within a matter of seconds. This quick cooling ensures the bottle retains its new shape.

- Releasing: After cooling, the bottle is released from the mold, now fully formed and ready for further processes like filling, labeling, and capping.

Producing plastic bottles efficiently requires precise control over temperatures, pressures, and timings. While the process is relatively fast, with a cycle time of approximately 15 to 30 seconds per bottle, the initial setup, especially for custom bottle shapes, can be expensive, with molds ranging from $10,000 to $50,000.

Comparison with Other Molding Processes

Let’s delve into the details of these processes to better understand their characteristics and how they compare to injection molding.

Extrusion Blow Molding

- Advantages:

- Speed: This process can produce items rapidly, often within a 20 to 30-second cycle time.

- Versatility: Suitable for producing a wide range of hollow products, from small medical containers to large barrels.

- Disadvantages:

- Limited Precision: The process may not achieve the same tight tolerances as injection molding. Typically, tolerances can vary by ±1 mm.

- Material Waste: Excess material, known as flash, often requires trimming.

- Cost: Machines can range in price from $20,000 for smaller machines to over $200,000 for larger, more complex systems.

Rotational Molding

- Process: Plastic powder is placed inside a mold, which is then heated and rotated on two axes. The plastic melts and coats the interior of the mold, creating the desired shape.

- Advantages:

- Uniform Wall Thickness: This process can produce items with a consistent wall thickness without thinning at the extremities.

- Low Tooling Costs: Molds are relatively less expensive compared to those for injection molding.

- Disadvantages:

- Slow Production Cycle: A single cycle can take 20 minutes to several hours.

- Limited Material Options: Not all plastics are suitable for rotomolding.

- Cost: Machines can start at around $50,000, with larger systems exceeding $500,000.

Thermoforming

Thermoforming involves heating a plastic sheet and using a mold to shape it into its final form.

- Process: A plastic sheet is heated to make it pliable and is then formed to a specific shape using a mold.

- Advantages:

- Rapid Prototyping: The process allows for quick production of prototypes or short runs.

- Flexibility: Suitable for large parts with relatively low tooling costs.

- Disadvantages:

- Material Limitations: Thicker materials can be harder to shape.

- Waste Production: Excess material around the mold often needs to be trimmed and discarded.

- Cost: Basic machines can be as low as $20,000, with advanced systems reaching upwards of $200,000.

Materials Used in Plastic Bottle Production

Plastic bottles are ubiquitous in today’s consumer world, from beverages and food items to cosmetics and cleaning products. Here’s an in-depth look at the primary materials utilized in the production of these bottles.

Polyethylene Terephthalate (PET)

- Properties:

- Clarity: PET offers a clear, glass-like appearance, making it suitable for products where visibility is key.

- Strength: It possesses high strength and resistance to impact, ensuring the bottle doesn’t break easily.

- Temperature Resistance: PET can typically handle temperatures up to 70°C without losing shape.

- Applications: Primarily used for water and soft drink bottles due to its clarity and barrier properties against carbonation and moisture.

- Cost: Prices for PET resin can fluctuate, but as of the last update, they ranged from $1,200 to $1,600 per metric ton.

High-Density Polyethylene (HDPE)

- Properties:

- Opacity: HDPE bottles are often opaque, making them ideal for products sensitive to light.

- Chemical Resistance: HDPE has excellent resistance to a broad range of chemicals, including acids and bases.

- Rigidity: It offers a stiffer feel compared to PET, which can be essential for certain packaging needs.

- Applications: HDPE is often used for milk jugs, detergent bottles, and containers for household chemicals.

- Cost: HDPE prices generally range from $900 to $1,300 per metric ton, depending on market conditions and grade.

Other Common Plastics

While PET and HDPE dominate the plastic bottle industry, other plastics also find specific applications:

- Polyvinyl Chloride (PVC): Known for its flexibility, PVC is used in the production of squeeze bottles, such as those for mustard. It has a cost range of $600 to $900 per metric ton.

- Low-Density Polyethylene (LDPE): This material, used in squeezable bottles like honey containers, offers flexibility and transparency. LDPE typically costs between $1,100 to $1,400 per metric ton.

Environmental Impact

The production and consumption of plastic bottles have seen exponential growth over the decades. With billions of bottles produced annually, the impact on our planet is significant, ranging from resource consumption to waste management challenges.

The Issue of Plastic Waste

The proliferation of plastic bottles poses a significant waste management challenge.

- Landfills: It’s estimated that about 60% of plastic bottles end up in landfills. Given the long degradation time of plastics – typically centuries for materials like PET and HDPE – they can occupy space for an extended period.

- Marine Pollution: Approximately 8 million metric tons of plastic enter our oceans annually. Floating bottles and bottle fragments pose threats to marine life, as animals may mistake them for food or become entangled.

- Resource Consumption: The production of plastic bottles requires vast amounts of water and energy. For instance, producing a 1-liter PET bottle can consume around 6 liters of water and significant energy, equivalent to filling the bottle one-quarter full of oil.

Recycling of Plastic Bottles

Recycling offers a path to mitigate some of the environmental issues associated with plastic bottles.

- Process: Bottles are collected, cleaned, and then shredded into flakes.

- Benefits:

- Resource Conservation: Recycling a ton of PET bottles can save up to 7.4 cubic yards of landfill space.

- Energy Savings: The energy required to recycle bottles is significantly less than producing them from raw materials. Recycling one plastic bottle can save enough energy to power a 60-watt light bulb for six hours.

- Challenges: Despite the advantages, only about 30% of plastic bottles are currently recycled. Factors like contamination, inefficient collection, and fluctuating market prices for recycled materials can hinder recycling rates.

Biodegradable and Bio-based Alternatives

The search for sustainable alternatives to traditional plastics has led to the development of biodegradable and bio-based plastics.

- Biodegradable Plastics: However, their degradation rate can vary based on environmental conditions and might not always be as quick as perceived.

- Bio-based Plastics: Derived from renewable resources like cornstarch or sugarcane, these plastics can offer a reduced carbon footprint. While it resembles PET in clarity and feel, it’s more suitable for short-shelf-life products due to its lower barrier properties.

- Challenges: While promising, these alternatives have limitations. Biodegradable plastics might still require specific conditions to degrade efficiently, and bio-based plastics can compete with food resources.