Yes, LDPE can be injection moulded. It’s flexible, cost-effective, and widely used for various applications despite some processing challenges.

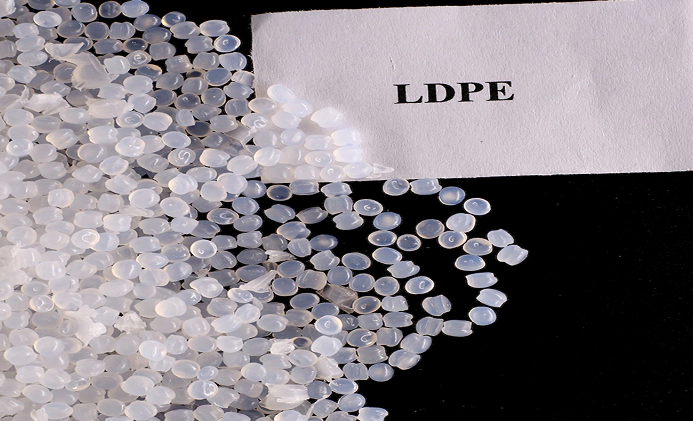

Understanding LDPE (Low-Density Polyethylene)

Low-Density Polyethylene, commonly known as LDPE, is a widely used type of thermoplastic polymer. Its unique molecular structure, characterized by its branching chain pattern, grants it distinct physical properties.

Composition and Properties

LDPE is composed primarily of carbon and hydrogen atoms, arranged in a polymer chain with significant branching. This branching reduces intermolecular forces, resulting in a lower density compared to other polyethylenes. Its melting point lies around 105°C to 115°C, which is relatively low among plastics, enhancing its moldability. The tensile strength of LDPE typically ranges from 0.20 to 0.40 GPa, and its impact resistance is notably high, ensuring durability in various applications.

Common Uses and Applications

The material’s electrical insulating properties also make it suitable for cable coverings and insulation applications. Explore various applications of LDPE.

Basics of Injection Moulding

Injection moulding stands as a pivotal process in the manufacturing industry, primarily for producing plastic parts with complex shapes and sizes. This method is highly efficient for mass production, offering consistency in quality and design.

Process Overview

Injection moulding involves melting plastic pellets and injecting the molten plastic into a mould under high pressure. The process begins with feeding plastic material into a heated barrel, where it melts. A screw mechanism then forces the molten plastic into a mould cavity. The plastic cools and solidifies in the mould, taking on the desired shape. Once cooled, the mould opens, and the part ejects. This process can produce parts ranging from simple to highly complex geometries, catering to diverse industry needs. The cycle time, crucial for production efficiency, varies depending on the part size and complexity but typically ranges from a few seconds to minutes. Discover more about injection moulding process.

Materials Compatibility

The selection of material in injection moulding is critical, as it directly impacts the part’s quality, durability, and cost. Various plastics are compatible with this process, including LDPE, HDPE, PP, ABS, and polycarbonate. Each material brings distinct properties: LDPE offers flexibility, HDPE provides strength, PP ensures chemical resistance, ABS boasts toughness, and polycarbonate excels in clarity and heat resistance. The choice of material depends on the intended use of the final product, considering factors like strength, flexibility, thermal and chemical resistance. For instance, automotive parts require materials with high durability and temperature resistance, while consumer packaging might prioritize flexibility and cost-effectiveness. Learn about different materials used in injection moulding.

LDPE in Injection Moulding

Low-Density Polyethylene (LDPE) presents unique opportunities and challenges in the realm of injection moulding. While it offers several benefits due to its properties, adapting the process to suit LDPE requires careful considerations.

Feasibility and Challenges

LDPE’s feasibility in injection moulding is significant, thanks to its low melting point and flexibility. However, this comes with its own set of challenges:

- Temperature Sensitivity: LDPE melts at approximately 105°C to 115°C, which is lower than many other plastics. This requires precise temperature control during the moulding process to prevent degradation.

- Shrinkage and Warping: LDPE parts tend to shrink and warp more than those made from stiffer plastics. Controlling the cooling rate and mould design can mitigate this.

- Cycle Time: Due to its low stiffness, LDPE parts might require longer cooling times, affecting the overall cycle efficiency.

Adjustments for LDPE Processing

To effectively mould LDPE, specific adjustments are necessary:

- Mould Design: Employing moulds with smoother surfaces and less intricate details can help in easy ejection of the finished part.

- Machine Settings: Lowering the injection and clamping pressure helps in reducing stress and warping on the final product.

- Cooling Systems: Implementing advanced cooling systems can help in managing the shrinkage and warping issues, ensuring dimensional accuracy.

Key Specifications:

- Melt Flow Index: LDPE typically has a Melt Flow Index of 0.3 to 30 g/10 min, indicating its flow characteristics under pressure.

- Tensile Strength: Ranges from 0.20 to 0.40 GPa, impacting how the material withstands stress during the moulding process.

- Cost Efficiency: The cost of LDPE is generally lower compared to materials like polycarbonate, making it a cost-effective option for large-scale production.

Comparative Analysis

LDPE vs Other Plastics in Injection Moulding

Comparing LDPE with other commonly used plastics in injection moulding reveals distinct differences in properties and suitability for various applications.

| Property | LDPE | HDPE | PP (Polypropylene) | ABS |

|---|---|---|---|---|

| Melting Point (°C) | 105-115 | 120-180 | 160-200 | 190-220 |

| Tensile Strength (GPa) | 0.20-0.40 | 0.20-1.5 | 0.35-0.80 | 1.5-2.5 |

| Flexibility | High | Moderate | Low | Low |

| Impact Resistance | High | Very High | Moderate | High |

| Cost (per kg) | Low | Moderate | Moderate | High |

| Shrinkage Rate (%) | High | Moderate | Low | Low |

This table illustrates the variations in melting points, tensile strength, flexibility, and other crucial parameters. LDPE, with its low melting point and high flexibility, offers advantages in applications requiring malleability. However, its high shrinkage rate can be a drawback in precision components.

Cost and Efficiency Considerations

When considering cost and efficiency in injection moulding, various factors come into play:

- Material Cost: LDPE generally costs less than other plastics like ABS or polycarbonate, making it an economical choice for large-scale production.

- Processing Efficiency: LDPE’s lower melting point can lead to faster cycle times, enhancing production efficiency. However, its high shrinkage may require additional time for cooling and finishing.

- Energy Consumption: Lower melting points mean reduced energy usage for heating, which can be a significant cost saver in mass production.

Detailed Cost Analysis:

- Average Cost per Kg:

- LDPE: $1.50 – $2.50

- HDPE: $1.80 – $3.00

- PP: $2.00 – $3.50

- ABS: $4.00 – $5.50

- Energy Efficiency:

- LDPE requires less energy to melt compared to ABS or PP, resulting in lower overall power consumption and cost.

Case Studies: LDPE Injection Moulding

Successful Applications

LDPE’s unique properties have led to its success in various applications. Some notable examples include:

- Flexible Containers: Due to its high flexibility, LDPE is ideal for creating squeeze bottles and flexible containers. These products benefit from LDPE’s resilience and durability.

- Medical Equipment: LDPE is used in non-sterile packaging for medical devices and containers for collecting samples. Its chemical resistance and safety profile make it suitable for such applications.

- Toys and Leisure Products: LDPE’s safety and flexibility are advantageous in manufacturing children’s toys, outdoor furniture, and leisure products.

Limitations and Solutions

While LDPE has broad applications, it also faces some limitations in injection moulding, along with potential solutions:

- Shrinkage and Warping:

- Issue: LDPE parts tend to shrink or warp due to its low stiffness.

- Solution: Implementing advanced cooling systems and optimizing mould design can help maintain dimensional accuracy.

- Processing Temperature:

- Issue: LDPE’s low melting point can lead to material degradation if not carefully managed.

- Solution: Precise temperature control and the use of specialized moulding machines can prevent degradation.

- Recycling and Sustainability:

- Issue: The environmental impact of plastic waste.

- Solution: Encouraging the use of recycled LDPE and implementing efficient recycling systems.

Cost Analysis:

- Material Cost: LDPE’s low cost (approximately $1.50 – $2.50 per kg) makes it an economical option for mass production.

- Production Efficiency: Modifications in process and design can offset LDPE’s longer cycle times due to cooling requirements, maintaining overall production efficiency.