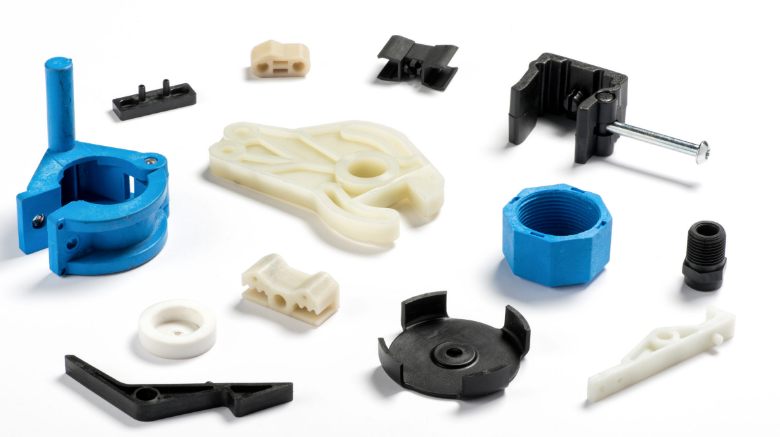

Typical injection molding products include plastic parts for automotive, electronics, packaging, and consumer goods industries.

Consumer Goods and Household Items

Injection molding plays a crucial role in the mass production of various consumer goods and household items.

Household Storage Containers

Material Selection: High-Density Polyethylene (HDPE) and Polypropylene (PP) are often used for their durability and flexibility.

Cost-Effectiveness: The cost per unit can be as low as a few cents, depending on the size and complexity of the container.

Design Flexibility: Injection molding allows for the creation of containers in various sizes and shapes, catering to diverse storage needs.

The versatility and affordability of injection-molded storage containers make them a popular choice in households.

Plastic Cutlery and Kitchenware

Plastic cutlery and kitchenware are ubiquitous in homes and the food industry.

Efficient Production: The speed of injection molding enables the production of thousands of units per hour, significantly reducing the cost and time.

Material Considerations: Polystyrene (PS) and Polypropylene (PP) are common due to their food-safe nature and low cost.

Lifecycle and Recycling: While these items are often single-use, advancements in biodegradable plastics and recycling processes are enhancing their sustainability.

The efficiency of producing plastic cutlery and kitchenware through injection molding aligns with the high-demand, fast-paced nature of the food industry.

Toys and Recreational Products

Injection molding is pivotal in creating a wide array of toys and recreational products.

Safety and Quality: Materials like ABS (Acrylonitrile Butadiene Styrene) are preferred for their strength and safety for children.

Color and Detail: This process allows for the integration of vibrant colors and intricate details, vital for the aesthetic appeal of toys.

Cost Efficiency: High-volume production capabilities ensure that the toys are affordable, with costs varying based on complexity and size.

The ability to produce high-quality, safe, and appealing toys makes injection molding an ideal choice for the toy industry.

For more information on the materials and processes involved, the Injection Molding page on Wikipedia provides extensive details.

Automotive Components

Injection molding is a cornerstone in the automotive industry, enabling the production of various components with precision and efficiency. This process is crucial for manufacturing parts like dashboard panels, exterior elements such as bumpers and headlights, and under-the-hood components.

Interior Parts such as Dashboard Panels

The manufacture of interior parts like dashboard panels leverages injection molding for its ability to produce complex shapes with high-quality finishes.

Cost-Effectiveness: The use of injection molding reduces manufacturing costs, making it possible to produce dashboard panels at a lower price point.

Design Flexibility: Injection molding allows for integrating intricate designs and ergonomic features into dashboard panels, enhancing both functionality and visual appeal.

Injection molding’s role in producing high-quality interior parts like dashboard panels is essential for modern vehicle design.

Exterior Elements like Bumpers and Headlights

Exterior automotive components such as bumpers and headlights require materials that can withstand environmental stresses while maintaining aesthetic appeal.

Material Durability: Polypropylene is typically used for bumpers due to its impact resistance, while polycarbonate is preferred for headlights for its clarity and durability.

Manufacturing Efficiency: Injection molding facilitates the production of large parts like bumpers and complex shapes like headlights, maintaining a high level of precision and quality.

Lifecycle Considerations: These components are designed to endure the vehicle’s life, emphasizing the importance of material quality and manufacturing precision.

The manufacturing of exterior automotive components through injection molding ensures both durability and aesthetic quality.

Under-the-Hood Components

Under-the-hood components require materials that can withstand high temperatures and mechanical stress.

Precision Manufacturing: Injection molding allows for the creation of parts with tight tolerances, essential for the proper functioning of engine components.

Cost and Efficiency: The process is cost-effective for producing high volumes of components, making it a preferred method in automotive manufacturing.

Injection molding’s precision and efficiency are crucial for producing reliable under-the-hood components in the automotive industry.

For more insights into the materials and techniques used, the Injection Molding page on Wikipedia offers comprehensive information.

Medical Devices and Equipment

Injection molding is crucial in medical manufacturing for its precision and cost-effectiveness.

Surgical Tools and Apparatus

This process is ideal for surgical tools requiring high precision and specific materials.

Materials: Stainless steel and biocompatible plastics are common.

Precision: Essential for complex surgical tools.

Cost: Mass production reduces per-unit costs.

Injection molding’s precision is vital for quality surgical tools.

Disposable Syringes and Drug Delivery Systems

These items benefit from injection molding’s efficiency and material compatibility.

Volume Production: Ideal for large-scale manufacturing.

Materials: Polypropylene is safe and durable.

Costs: The process keeps prices low.

Efficiency makes injection molding essential for disposable items.

Prosthetics and Orthopedic Devices

Customization and material strength are key for these devices, and injection molding excels here.

Customization: Tailors devices to individual needs.

Materials: Uses strong, flexible plastics.

Durability: Long-lasting, reducing replacements.

Injection molding’s adaptability is crucial for prosthetics.

For more, see the Injection Molding Wikipedia page.

Electronic and Electrical Products

Injection molding is a key manufacturing process in the electronics industry, known for its precision, efficiency, and versatility in producing a wide range of components.

Enclosures for Consumer Electronics

Enclosures for devices like smartphones, laptops, and televisions are typically made using injection molding.

Material Choices: ABS and polycarbonate are popular for their durability and aesthetic appeal.

Design and Customization: This process allows for intricate designs and branding options.

Cost Efficiency: Injection molding enables mass production at a lower cost, making electronics more affordable.

The ability of injection molding to create detailed and durable enclosures is essential in the consumer electronics market.

Components for Electrical Appliances

Electrical appliances contain numerous injection-molded parts, from internal mechanisms to external housings.

Functional Materials: Materials like Nylon are used for their heat resistance and strength.

Complex Shapes: Injection molding allows for producing complex shapes needed in electrical components.

Production Scale: The process is efficient for large-scale production, keeping appliance costs manageable.

Injection molding’s efficiency in producing complex components makes it indispensable in appliance manufacturing.

Connectors and Insulation Parts

Connectors and insulation parts are critical for safety and functionality in electronics.

High Precision: These parts require high precision for proper electrical function.

Material Properties: Flame-retardant plastics are often used for safety.

Cost and Efficiency: The process is cost-effective for producing these small, intricate parts.

The precision and material flexibility of injection molding are crucial for producing safe and reliable electronic components.

For further information, the Injection Molding page on Wikipedia offers comprehensive insights.