Yes, 3D printing can achieve similar strength to injection molding when using appropriate materials and techniques.

Mechanical Properties in 3D Printing vs. Injection Molding

Tensile Strength Analysis

In 3D printing, materials usually exhibit a tensile strength ranging from 30 to 80 MPa. In contrast, injection molding can achieve strengths of 100-150 MPa. This difference is due to the layer-by-layer building method in 3D printing, which may create weak points, whereas injection molding produces a more uniform and robust molecular structure.

Impact Resistance and Toughness

3D printed materials generally have lower impact resistance, withstanding 20-30 Joules of energy. Injection molded materials are tougher, enduring impacts up to 50-70 Joules. The higher toughness in injection molding is attributed to its continuous material structure.

Thermal Properties and Stability

The thermal stability of 3D printed parts varies, with most materials handling 60°C to 150°C. Injection molded parts demonstrate superior thermal properties, often withstanding up to 200°C or more. This enhanced thermal stability makes injection molding suitable for high-temperature applications.

Longevity and Wear Resistance

3D printed parts typically have a lifespan of 5-10 years, whereas injection molded parts can last 15-20 years or more. The wear resistance in injection molding is significantly higher due to the material’s homogeneity and density. Injection molding is preferable for applications requiring long-term durability.

For comprehensive insights on material properties and their influence on product quality, refer to the Wikipedia page on 3D Printing Materials and Injection Molding Materials.

Comparative Analysis of 3D Printing and Injection Molding

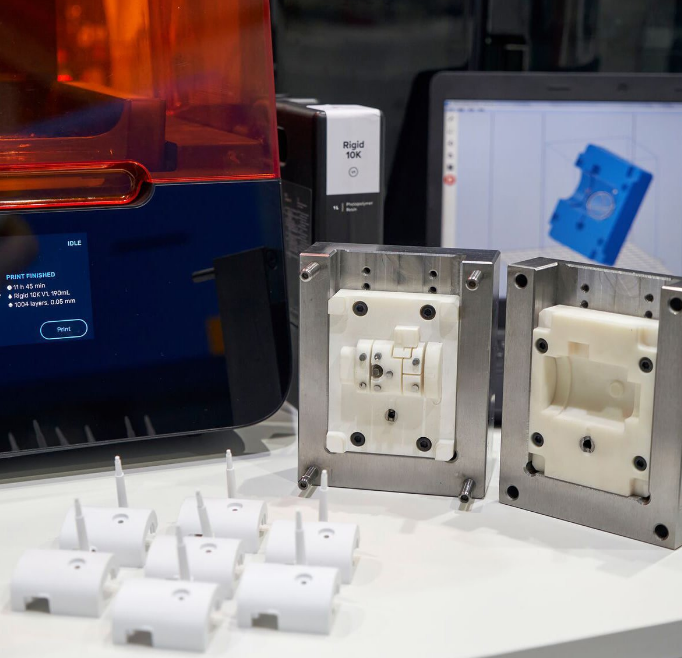

Overview of 3D Printing Technology

3D printing, a revolutionary technology, builds objects layer by layer, allowing for complex designs. It’s ideal for rapid prototyping and custom parts.

Speed: Typically ranges from 20 to 100 mm/s.

Cost: Generally, material costs are about $0.10 to $1.00 per gram.

Material Choices: Includes a variety like ABS, PLA, metals, and resins.

Key Benefits: Excellent for custom designs and complex geometries.

Constraints: Comparatively lower strength; size limitations; slower for bulk production.

For further details, visit the 3D Printing Wikipedia page.

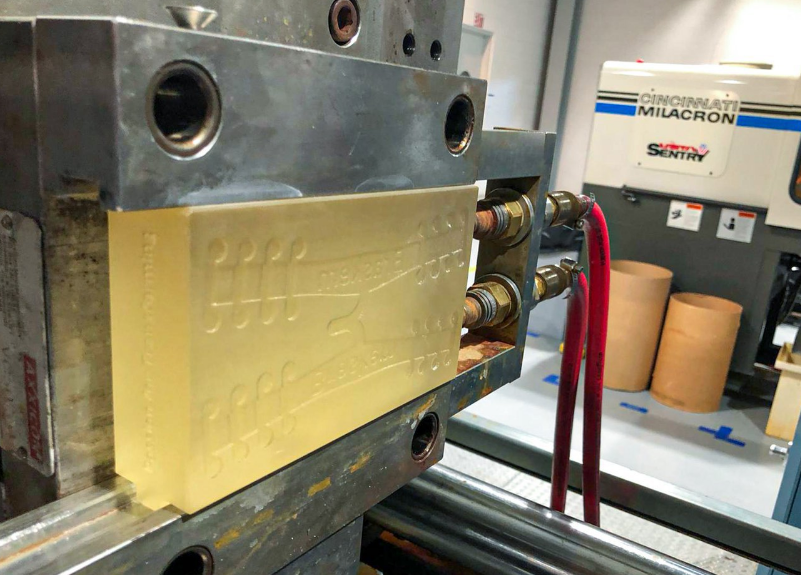

Overview of Injection Molding Process

Injection molding, a mainstay in mass production, involves injecting molten material into molds. It’s known for producing strong, consistent parts efficiently.

Speed: Highly efficient, capable of producing thousands of parts per hour.

Cost Implications: Higher initial setup costs but more cost-effective for large volumes.

Material Spectrum: Primarily uses thermoplastics and metals.

Advantages: Consistent quality and excellent for high-volume production.

Drawbacks: Higher initial costs and less flexibility in design.

Detailed information is available on the Injection Molding Wikipedia page.

Material Properties and Selection in Both Methods

The choice of materials is crucial in both 3D printing and injection molding, impacting the final product’s properties.

3D Printing Materials: Offer versatility including flexible and specialized options.

Injection Molding Materials: More focused on plastics and metals suitable for high-temperature processes.

Strength and Durability Comparisons

A comparative analysis of the strength and durability offered by 3D printing and injection molding:

| Feature | 3D Printing | Injection Molding |

|---|---|---|

| Tensile Strength | 30-80 MPa | 100-150 MPa |

| Impact Resistance | Lower (20-30 Joules) | Higher (50-70 Joules) |

| Thermal Stability | 60°C to 150°C | Up to 200°C or more |

| Lifespan | 5-10 years | 15-20 years or more |

| Wear Resistance | Lower due to the layering process | Higher, thanks to material consistency |

| Production Efficiency | Optimal for small-scale, custom projects | Best suited for large-scale, consistent production |

Design Flexibility and Limitations

Complex Geometries in 3D Printing

3D printing excels in creating complex geometries, offering unparalleled design flexibility. It allows for intricate designs that are often impossible to achieve through traditional manufacturing methods. This capability stems from the additive nature of 3D printing, building objects layer by layer. However, the strength of these complex structures can be a concern, as the layered approach might lead to weaker points compared to a uniformly molded part.

Size and Volume Constraints in Injection Molding

While injection molding is efficient for large-scale production, it has limitations regarding the size and volume of parts. The size of the part is restricted by the capacity of the injection molding machine, which can be a significant investment for larger machines. This method is less flexible when it comes to changing designs, as each new part requires a new mold, adding to the cost and time.

Surface Finish and Aesthetic Considerations

Injection molding typically results in parts with excellent surface finish and aesthetic qualities. The process allows for smooth, textured, or detailed surfaces. 3D printing, on the other hand, may require post-processing to achieve a similar level of finish. The layering effect in 3D printing can leave visible lines, impacting the final appearance and texture.

Customization and Prototyping Capabilities

3D printing is highly beneficial for customization and rapid prototyping. Its ability to quickly produce a single custom part makes it ideal for bespoke designs or prototypes, where speed and adaptability are crucial. Injection molding, with its higher setup costs and longer lead times, is less suited for one-off productions or rapid design changes.

For a deeper understanding of these technologies, their applications, and limitations, explore the Wikipedia page on 3D Printing and Injection Molding.

Cost and Production Efficiency

Material Costs and Availability

In 3D printing, material costs can vary significantly, typically ranging from $0.10 to $1.00 per gram, depending on the type of material used (e.g., ABS, PLA, resin). The availability of these materials is generally high, with a growing market supporting a wide range of options. For injection molding, material costs are often lower at scale, but the initial investment in mold design and setup can be substantial. This method is heavily dependent on the availability of bulk material supplies, which can influence overall cost efficiency.

Production Time and Scalability

3D printing is known for its rapid prototyping capabilities, often completing small runs within hours or days. However, its scalability is limited when it comes to large-scale production. Injection molding, conversely, has longer initial setup times due to mold design and manufacturing, but once operational, it can produce large quantities efficiently, making it ideal for mass production.

Energy Consumption and Environmental Impact

Energy consumption in 3D printing can be high, especially for large, intricate designs. However, the additive nature of this technology often results in less material waste. Injection molding, while energy-intensive during the production phase, is efficient in terms of material usage, with minimal waste. Both technologies have a varying environmental impact, dependent on the materials used and the efficiency of the processes.

Economic Viability for Different Scales of Production

3D printing shines in small-scale, custom production, where its flexibility and lower initial investment can be highly cost-effective. Injection molding, in contrast, becomes economically viable at larger scales. The high initial costs for mold creation are offset by the lower per-unit cost for high-volume runs. The choice between these two depends on the scale of production and the specific financial constraints of the project.

For further insights into the costs and efficiencies of these manufacturing methods, the Wikipedia page on 3D Printing and Injection Molding offer detailed information.