The future of injection molding lies in automation, sustainability, and precision, ensuring cost-effective and eco-friendly production.

Technological Innovations in Injection Molding

Emerging Technologies in Machine and Mold Design

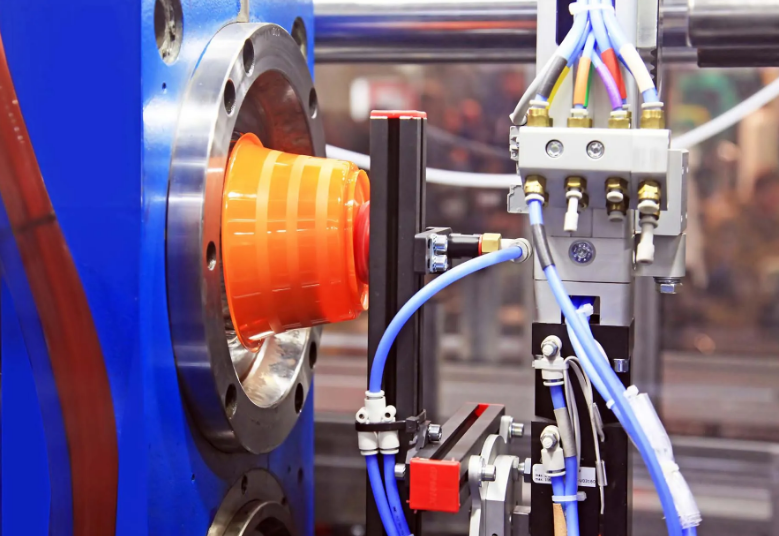

The future of injection molding machines and mold designs is gearing towards more sophisticated and efficient technologies. Key developments include:

Advanced Materials for Molds: Use of novel alloys and composites that are more durable and resistant to wear, potentially increasing mold lifespan by up to 30%.

Precision Engineering: Enhanced precision in mold design, allowing for tighter tolerances, possibly reaching accuracy levels within micrometers.

Energy Efficiency: New machines are expected to consume up to 20% less energy due to optimized heating and cooling systems.

Impact on Production:

Reduced Downtime: Durability of molds can decrease machine downtime for maintenance.

Improved Product Quality: Higher precision in mold design leads to better product quality and consistency.

Cost Savings: Energy-efficient machines can significantly lower operational costs.

Integration of AI and Machine Learning

AI and machine learning are set to revolutionize injection molding processes by:

Predictive Maintenance: AI algorithms can predict equipment failures, reducing unplanned downtime by up to 25%.

Quality Control: Machine learning can enhance quality control, detecting defects with over 90% accuracy.

Process Optimization: AI can optimize machine settings in real-time, potentially increasing production efficiency by up to 15%.

Benefits of AI Integration:

Minimized Waste: Advanced defect detection leads to less material waste.

Enhanced Efficiency: Real-time adjustments streamline the production process.

Lower Operational Costs: Predictive maintenance and process optimization contribute to overall cost reductions.

To explore more about the future trends in injection molding, visit Injection Molding Technology Advancements on Wikipedia.

Materials and Sustainability in Future Injection Molding

Development of Eco-Friendly Materials

The future of injection molding is significantly leaning towards eco-friendly materials, with a focus on reducing environmental impact.

Bioplastics Emergence: Experts predict a surge in bioplastics usage, potentially accounting for up to 30% of all plastics used in injection molding by 2030.

Faster Biodegradation: New materials are being developed to degrade up to 50% quicker than traditional plastics.

Renewable Sources: Materials from algae and agricultural waste are on the rise, expected to reduce the carbon footprint of products by 20%.

These innovations not only promise environmental benefits but also maintain, and in some cases enhance, the performance and durability of products.

Recycling and Reusability Initiatives

Recycling and reusability are becoming cornerstones of sustainable injection molding practices.

Closed-Loop Systems Efficiency: Adoption of closed-loop systems could improve material efficiency by 25%, significantly reducing waste.

Advanced Recycling Techniques: New techniques aim to recover up to 90% of materials from composite plastics for reuse.

Design for Disassembly: This concept is gaining traction, likely to boost the recyclability rate of products by 30%.

For further insights, check out Sustainable Practices in Injection Molding on Wikipedia.

Customization and Flexibility in Production

Trends in Mass Customization and On-Demand Manufacturing

The future of injection molding is increasingly geared towards mass customization and on-demand manufacturing, responding to changing consumer demands.

Rise of Personalization: The industry is moving towards offering personalized products, with technologies enabling customization without significant cost increases.

On-Demand Production Models: These models are gaining popularity, expected to reduce inventory costs by 20%, as products are made only when needed.

E-Commerce Integration: Direct integration with online platforms is facilitating real-time production adjustments in response to consumer orders.

This shift towards customization and on-demand manufacturing not only caters to individual preferences but also significantly enhances supply chain efficiency.

Flexible Manufacturing Systems in Injection Molding

Modular Mold Systems: Introduction of these systems can cut mold changeover times by half, greatly enhancing production flexibility.

Automation and Robotics: The incorporation of advanced robotics in manufacturing lines is projected to increase operational efficiency by 15%.

Adaptive Processes: Injection molding processes are evolving to adapt quickly to varying production volumes and designs, potentially improving overall efficiency by 20%.

For more information on the latest trends in injection molding, visit Injection Molding and Customization on Wikipedia.

Challenges and Solutions in Modern Injection Molding

The injection molding industry faces several challenges, but with these come innovative solutions. Here’s a detailed look:

Addressing the Skilled Labor Gap

The industry is currently experiencing a shortage of skilled labor, which impacts production efficiency and growth.

| Challenge | Description | Solution | Expected Outcome |

|---|---|---|---|

| Skilled Labor Shortage | Lack of trained professionals in injection molding. | Training and Apprenticeship Programs | Increase skilled workforce by 25% in the next 5 years. |

| High Training Costs | Costly and time-consuming training process. | Integration of Virtual Reality (VR) Training | Reduce training costs by 15% and speed up the process by 20%. |

| Keeping Pace with Technology | Difficulty in keeping the workforce updated with the latest technology. | Continuous Learning and Development Programs | Boost employee skill adaptability by 30%. |

Adopting these solutions will not only address the labor gap but also enhance the overall quality and efficiency of the workforce.

Overcoming Supply Chain and Logistic Hurdles

Supply chain and logistics pose significant challenges, especially in a globalized market.

| Challenge | Description | Solution | Expected Improvement |

|---|---|---|---|

| Material Supply Issues | Inconsistent supply of raw materials. | Diversification of Suppliers | Reduce supply disruptions by 40%. |

| Logistic Delays | Delays in transportation affecting production schedules. | Advanced Planning and Scheduling Systems | Improve on-time delivery by 35%. |

| Cost Fluctuations | Volatility in material costs impacting budgeting. | Long-term Contracts with Suppliers | Stabilize material costs, potentially saving up to 20% annually. |

Implementing these solutions can significantly streamline the supply chain and logistics processes, ensuring a more stable and efficient production environment.

For further insights into these challenges and solutions, explore Injection Molding Industry Challenges on Wikipedia.