Transfer moulding offers precision for complex parts; injection moulding excels in high-volume, cost-effective production.

Overview of Moulding Techniques

Moulding techniques stand as critical processes in the manufacturing sector, shaping materials into desired forms using various methods. Among these, transfer moulding and injection moulding are prominent for their unique approaches and applications.

Definition of Transfer Moulding

Transfer moulding involves heating a material, typically a thermosetting plastic, and then transferring it under pressure into a closed mould. This process allows for precise control over dimensions, leading to high-quality finished products. Transfer moulding is especially beneficial when dealing with intricate shapes or parts requiring inserts. The method excels in producing consistent and high-strength parts, making it a go-to choice for electronic components and similar applications.

Definition of Injection Moulding

Injection moulding, on the other hand, involves melting plastic granules and injecting them under high pressure into a mould cavity. This technique is renowned for its high production speed and efficiency. Injection moulding is versatile, accommodating a wide range of materials and allowing for the creation of complex geometries with excellent surface finish. It is a preferred method for mass-producing plastic parts, such as automotive components, containers, and toys.

Key Advantages of Transfer Moulding:

- Enhanced dimensional accuracy and stability

- Superior strength in finished products

- Ideal for intricate designs and embedded parts

Key Advantages of Injection Moulding:

- High production speed and efficiency

- Versatility in materials and design

- Cost-effectiveness for large-scale production

In terms of costs, transfer moulding generally involves higher initial setup costs due to the complexity of the moulds. However, it offers lower waste levels and less material usage. Injection moulding, while having lower per-unit costs, may incur higher material costs and waste.

Material Quality and Specifications play a pivotal role in both processes. Transfer moulding typically uses thermosetting plastics like epoxy or phenolic resins, known for their heat resistance and mechanical strength. Injection moulding often utilizes thermoplastics like polyethylene or polystyrene, valued for their flexibility and recyclability.

Process Mechanics

Understanding the mechanics of moulding processes is essential for optimizing manufacturing efficiency and product quality. The mechanisms of transfer moulding and injection moulding, while sharing similarities, exhibit distinct operational principles and outcomes.

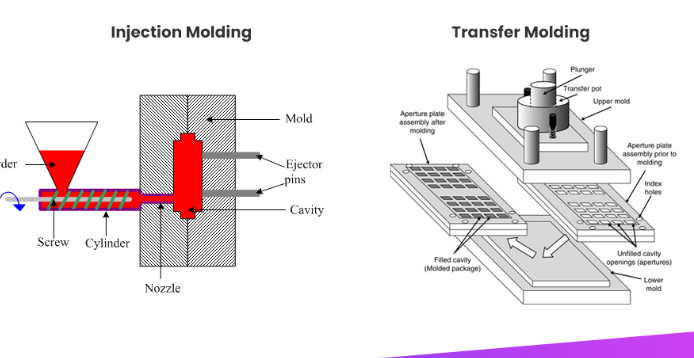

Mechanism of Transfer Moulding

Transfer moulding starts with placing a pre-measured amount of moulding material in a chamber above the mould. As the material heats, it reaches a molten state. A plunger then applies pressure, forcing the material through channels into the mould cavity. This process allows for precise control of material volume, ensuring uniform part weight and dimensions. The heat and pressure are maintained until the material cures, solidifying into the desired shape.

Key aspects of transfer moulding include:

- Controlled material flow minimizes waste.

- Pressure application ensures material fills complex geometries.

- Ideal for smaller production runs with high precision requirements.

Mechanism of Injection Moulding

Injection moulding begins by feeding plastic pellets into a heated barrel. Inside the barrel, a rotating screw both melts the pellets and injects the molten plastic into the mould cavity under high pressure. This high-pressure injection ensures detailed replication of the mould’s surface. Once the plastic cools and solidifies, the mould opens to eject the finished part.

Highlights of injection moulding are:

- High production rates due to fast cycle times.

- Consistent quality across large batches.

- Flexibility in using a wide range of plastic materials.

Materials Used in Moulding

Selecting the right materials for moulding processes like transfer moulding and injection moulding is crucial. The choice impacts not only the quality and performance of the final product but also the efficiency and cost-effectiveness of the manufacturing process.

Material Requirements for Transfer Moulding

Transfer moulding primarily uses thermosetting polymers. These materials, once set, cannot be melted and reshaped, making them ideal for high-heat applications. Common thermosetting materials include:

- Epoxy Resins: Known for their high strength and chemical resistance, they are often used in electronics and automotive parts. Epoxy resins offer a balance between performance and cost, typically ranging from moderate to high in price.

- Phenolic Resins: Widely used due to their fire-resistant properties and mechanical strength. They are cost-effective, making them suitable for bulk production.

- Silicone Rubbers: These offer excellent heat resistance and flexibility. While more expensive, they are essential for specific applications like medical devices.

The choice of material affects the moulding parameters such as temperature, which usually ranges from 130°C to 160°C, and pressure, often between 1,000 to 2,000 psi. These parameters are key to achieving optimal material flow and curing.

Material Requirements for Injection Moulding

Injection moulding predominantly uses thermoplastics, which can be melted, moulded, and then remelted if needed. Popular thermoplastics include:

- Polyethylene (PE): Offers versatility and low cost, suitable for a wide range of products from containers to automotive parts.

- Polypropylene (PP): Known for its chemical resistance and elasticity, PP is commonly used in packaging, textiles, and automotive components.

- Polystyrene (PS): Easy to mould and cost-effective, it is used for disposable cutlery, CD cases, and insulation materials.

In injection moulding, the material’s flow rate is crucial. It dictates the injection speed, which can vary significantly based on the part’s complexity and size. For instance, simpler parts may require a flow rate of 30-60 cm³/s, while more complex designs might need over 100 cm³/s.

Applications and Uses

Transfer moulding and injection moulding, each with their unique properties and capabilities, cater to a diverse range of applications across various industries. Understanding these applications highlights the versatility and specific advantages of each moulding technique.

Typical Applications of Transfer Moulding

Transfer moulding finds its niche in creating parts that demand high precision and intricate designs. Some of the key applications include:

- Electrical Components: Such as switches, connectors, and sensors. Transfer moulding’s ability to encapsulate metal parts with plastic makes it ideal for producing complex electronic components that require high dimensional accuracy and electrical insulation.

- Automotive Parts: Components like under-hood connectors and sensor housings benefit from the heat-resistant qualities of thermosetting plastics used in transfer moulding.

- Medical Devices: Prosthetics and implantable devices often utilize transfer moulding due to the need for biocompatible and high-strength materials.

In these applications, the specific properties of materials used in transfer moulding, like heat resistance and chemical stability, are crucial. The manufacturing cost, while higher than injection moulding for large volumes, is justified by the quality and performance of the end product.

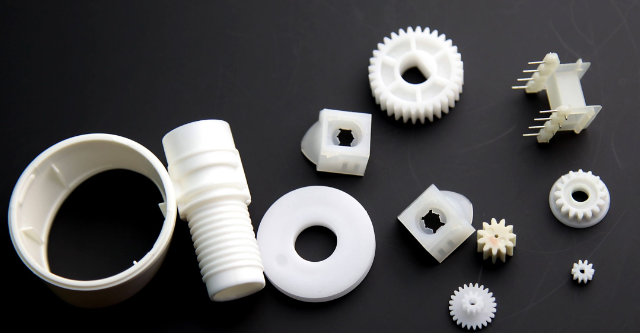

Typical Applications of Injection Moulding

Injection moulding’s versatility allows it to cater to a vast array of industries, making it one of the most widely used manufacturing processes. Some notable applications are:

- Consumer Products: Items like plastic bottles, containers, and toys. The efficiency and high output rate of injection moulding make it suitable for producing these items on a large scale.

- Automotive Components: Parts such as bumpers, dashboards, and interior panels. The ability to use various types of plastics, including durable and lightweight materials, is a significant advantage in automotive applications.

- Packaging Materials: Injection moulding is extensively used to produce packaging solutions, including caps, lids, and other closure systems.

Advantages and Disadvantages

Delving into the pros and cons of transfer moulding and injection moulding offers insights into their suitability for various manufacturing scenarios. Each method has its unique strengths and limitations, impacting decision-making in the industrial sector.

Pros and Cons of Transfer Moulding

Advantages of Transfer Moulding:

- High Precision and Quality: Yields products with excellent dimensional stability and detail, making it ideal for complex designs.

- Lower Material Waste: Excess material can often be reused, leading to more efficient material utilization.

- Suitable for High-Value Products: Offers superior properties like heat resistance and strength, essential for electronics and automotive components.

Disadvantages of Transfer Moulding:

- Higher Cost for Large Volumes: Due to the process’s nature, it becomes less cost-effective for mass production compared to injection moulding.

- Longer Cycle Times: Slower than injection moulding, impacting the overall production speed.

- Limited to Thermosetting Plastics: This restricts the range of materials that can be used.

Pros and Cons of Injection Moulding

Advantages of Injection Moulding:

- Efficiency and Speed: Suitable for high-volume production due to its fast cycle times.

- Versatility in Materials: Can process a wide range of thermoplastic materials.

- Cost-Effectiveness for Mass Production: Lower per-unit cost makes it ideal for large-scale manufacturing.

Disadvantages of Injection Moulding:

- High Initial Costs: The cost of mould design and machine setup is significant, though it pays off in large-scale production.

- Limited to Simpler Part Designs: While capable of intricate designs, it has limitations compared to transfer moulding in terms of undercuts and very complex geometries.

- Potential for Material Waste: Sprues and runners in the mould can lead to material wastage, although recycling is possible with thermoplastics.

The table below summarizes these points for a quick comparison:

| Aspect | Transfer Moulding | Injection Moulding |

|---|---|---|

| Precision and Quality | High | Moderate to High |

| Material Waste | Lower | Higher |

| Suitability for Volume | Low to Medium | High |

| Cycle Time | Longer | Shorter |

| Material Range | Limited (Thermosetting) | Wide (Thermoplastics) |

| Cost for Large Volumes | Higher | Lower |

| Initial Setup Cost | Moderate | High |

| Design Complexity | Suitable for Complex Parts | Less Suitable for Extremely Complex Parts |

Cost and Efficiency Analysis

Analyzing the cost and efficiency of transfer moulding and injection moulding is vital to understand their economic impact and operational suitability in the manufacturing industry.

Cost Analysis of Transfer Moulding

Factors Influencing Costs in Transfer Moulding:

- Mould and Setup Costs: Transfer moulding requires complex moulds, which can be expensive to design and manufacture. However, these costs are generally lower compared to those for injection moulding.

- Material Costs: The thermosetting plastics used in transfer moulding can vary in price, but are typically more expensive than thermoplastics used in injection moulding. The cost effectiveness increases with the volume of production.

- Operational Costs: Includes energy consumption and labor. Transfer moulding machines are usually less energy-intensive than injection moulding machines, but the slower cycle times might increase labor costs.

Efficiency Considerations:

- Transfer moulding offers high precision and quality, which can reduce the need for post-production finishing, thereby saving costs.

- Ideal for medium-volume production, where the balance between setup costs and per-unit cost is optimized.

Cost Analysis of Injection Moulding

Factors Influencing Costs in Injection Moulding:

- Initial Investment: High due to the cost of creating detailed moulds and purchasing advanced machinery.

- Material Costs: Generally lower, as thermoplastics are more affordable than thermosets. Bulk purchasing often leads to further cost reductions.

- Production Efficiency: High-speed production and shorter cycle times decrease labor and operational costs.

Efficiency Considerations:

- Ideal for high-volume production where the initial high costs are offset by the lower per-unit cost.

- Energy consumption per unit is lower due to faster production times, making it more cost-effective in large-scale operations.

Comparative Summary:

- Transfer moulding is more suitable for smaller to medium production runs where its high precision and quality justify the costs.

- Injection moulding is cost-efficient for large-scale production due to its high output rate and lower material costs.