Injection moulding for large products faces higher costs, technical challenges, and significant environmental concerns.

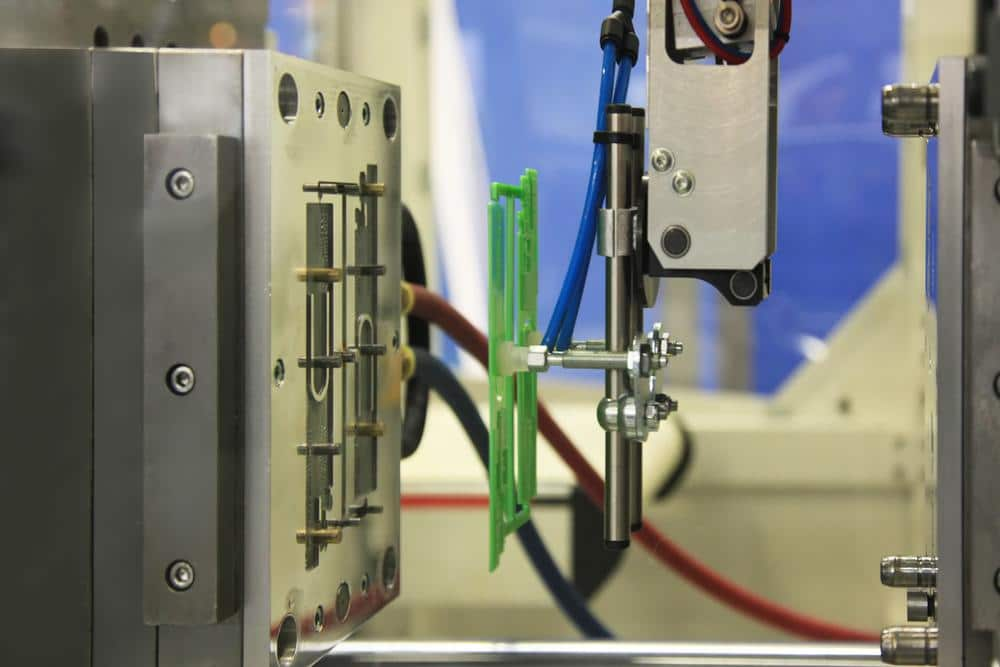

Challenges in Moulding Large Products

Injection moulding is a popular manufacturing process due to its efficiency and versatility. However, when it comes to producing large products, several challenges arise.

Size Limitations of Injection Moulding Machines

One of the primary constraints in moulding large products is the size limitation of injection moulding machines. These machines have a maximum capacity, often defined by parameters such as clamping force and shot volume. For instance, a typical machine might have a clamping force ranging from 15 to 6,000 tons and a shot volume capacity of up to 6000 cubic centimeters. This size limitation restricts the maximum dimensions of the product that can be moulded. Manufacturing a product larger than these parameters would require a custom-built machine, significantly increasing the cost. For detailed specifications of injection moulding machines, the Wikipedia page on Injection Moulding provides comprehensive information.

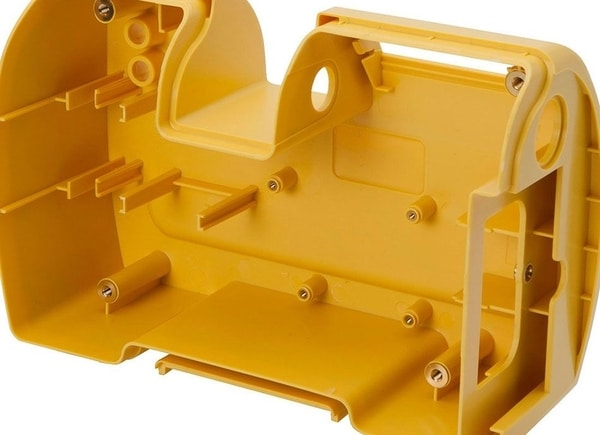

Quality Issues in Large Part Production

Quality control becomes increasingly challenging as the size of the product increases. In large part production, issues such as warping, sink marks, and uneven cooling are common. These defects arise due to uneven temperature distribution during the moulding process. For example, thicker sections of a large part might cool slower than thinner sections, leading to internal stresses and warping. Additionally, maintaining a consistent material flow and pressure throughout the large mould cavity is difficult, often resulting in areas of lower quality within the part.

Material Considerations

When it comes to injection moulding, especially for large products, the choice of material plays a crucial role. The material not only determines the product’s properties but also influences the manufacturing process significantly.

Material Constraints for Large-Scale Moulding

Different materials pose unique challenges in large-scale moulding. For instance, some plastics may shrink excessively or unevenly, leading to defects in large parts. Materials with high shrinkage rates, like polyethylene or polystyrene, can cause dimensional inaccuracies in larger moulds. These inaccuracies are more pronounced in larger parts due to the increased distance over which the material must maintain its integrity. The shrinkage rate of a material is a critical parameter to consider, and specific values can be found on materials databases and Wikipedia.

Moreover, certain materials have limitations in terms of their flow properties. Materials with high viscosity require more pressure to fill the mould, which can be problematic for large moulds. The pressure required to inject the material into the mould is directly related to the size and design of the part. For example, a material with a viscosity of 1000 Pa.s might require a pressure of up to 2000 bar to fill a large mould, whereas a less viscous material might only need 1200 bar. These specifics significantly impact the cost and efficiency of the production process.

Impact of Material Behavior on Large Parts

The behavior of materials under different conditions can significantly affect the quality of large parts. For example, materials that are prone to warping or distortion under high temperatures or during cooling can lead to defects in large-sized products. This is particularly important for materials like ABS or polycarbonate, known for their susceptibility to thermal deformation.

Additionally, the endurance and stability of materials over time are critical for large parts. Materials that degrade or lose their properties over time can affect the lifespan and safety of the product. For instance, a material’s UV resistance is crucial for products used outdoors, as prolonged exposure to sunlight can degrade certain plastics. The UV resistance of various plastics is a factor often detailed in material specifications and can be found in resources like the Wikipedia page on Polycarbonate.

Technical Difficulties

Injection moulding large products brings a host of technical challenges. These difficulties stem primarily from managing the physical properties of materials over large volumes and the complexities involved in designing and fabricating large moulds.

Managing Temperature and Cooling Times

- Uneven Cooling Rates: Large parts cool unevenly, leading to areas of differential shrinkage and potential warping. The thicker sections of a part might retain heat longer, causing them to shrink differently from thinner sections.

- Extended Cooling Times: Larger parts require more time to cool, significantly lengthening the cycle time of each moulding operation. For example, a small part might cool in 30 seconds, but a large part could take several minutes or more.

- Temperature Control Challenges: Maintaining a consistent temperature across a large mould is complex. Hotspots and cold spots can develop, affecting the flow and setting of the material.

- Increased Energy Consumption: More energy is necessary to maintain the required temperatures for large moulds, impacting both cost and environmental footprint.

Complexities in Design and Mould Fabrication

- Design Precision: Larger moulds require extremely precise design to ensure uniform flow of material and consistent cooling. Even minor errors in design can lead to significant defects in large parts.

- Mould Fabrication Difficulties: The fabrication of large moulds involves intricate machining and finishing work. These tasks become more challenging as the size of the mould increases.

- Material Selection for Moulds: Choosing the right material for the mould is critical. The mould material must withstand high pressures and temperatures without deforming. For large moulds, this requirement becomes more critical due to the increased volume of material and longer cycle times.

- Handling and Storage: Large moulds are cumbersome to handle and require special equipment for moving and storage. This necessity adds logistical complexity and cost.

Cost Implications

The cost implications of injection moulding large products are significant and multifaceted, affecting the overall feasibility and profitability of a project. Understanding these cost factors is essential for making informed decisions in the manufacturing process.

Increased Cost for Large Mould Tools

The cost of manufacturing mould tools increases substantially with size. Large moulds require more material, which directly raises the expense. For instance, a mould for a small plastic part might cost around $1,000 to $5,000, whereas a large mould can easily exceed $20,000 to $50,000, depending on complexity and material.

Additionally, the machining time and labor involved in making large moulds contribute to the higher cost. Precision machining of a large mould can take hundreds of hours, as it involves intricate design and detailed finishing. The cost of labor for such skilled work is significant and adds to the overall expense.

Furthermore, large moulds often require specialized machinery for fabrication, which may not be available in standard mould-making facilities. This necessity for specialized equipment or outsourcing can further increase the cost.

Cost Efficiency in Producing Large Volumes

While the initial investment in large mould tools is high, producing large volumes can offset this cost. The per-unit cost of production decreases with the number of parts produced due to economies of scale. For example, if the cost of a large mould is $50,000, the mould cost per unit for a production run of 1,000 units would be $50, but it drops to $5 per unit for a run of 10,000 units.

Environmental Concerns

Injection moulding, especially for large products, raises several environmental concerns. These issues primarily revolve around energy consumption and waste management, which are crucial in the context of sustainable manufacturing practices.

Energy Consumption in Large Part Production

- High Energy Requirements: The production of large parts demands a significant amount of energy. Heating and cooling large volumes of material in the moulding process consume more energy compared to smaller parts. For example, the energy consumption for moulding a large automotive part might be several times higher than that for a small electronic component.

- Longer Cycle Times and Increased Energy Usage: Since large parts have longer cooling times, the machines operate for extended periods, leading to higher energy consumption. This prolonged operation means that a large moulding machine might consume several kilowatts per hour more than a machine used for smaller parts.

- Impact on Carbon Footprint: The increased energy usage directly translates to a larger carbon footprint. Manufacturing facilities that specialize in large parts often have a higher overall environmental impact due to this increased energy demand.

Waste Management and Recycling Challenges

- Higher Volume of Material Waste: Large part production inevitably leads to a higher volume of waste, including sprues, runners, and defective parts. Managing this waste efficiently is a significant challenge.

- Recycling Complexities: Recycling the materials used in large parts can be more complex. The size and complexity of the parts might make them harder to break down and process for recycling. For instance, a large plastic automotive component may require specialized equipment to grind it down for recycling.

- Disposal Issues: When recycling is not feasible, disposing of large plastic parts becomes an environmental concern. Landfill space and the impact of non-biodegradable materials on the environment are critical considerations.

- Encouraging Sustainable Practices: Manufacturers are exploring ways to minimize waste, such as using biodegradable materials or optimizing the design to reduce excess material use. Innovations in this area are crucial for reducing the environmental impact of large part production.