Evaluating Nylon Grades for Specific Applications

Choosing the right nylon grade for a specific application involves considering various factors such as mechanical properties, environmental resistance, and cost-effectiveness. Different grades of nylon offer distinct advantages depending on the application’s requirements.

Impact of Moisture Absorption on Nylon Performance

Nylon’s mechanical properties significantly depend on its moisture content. Moisture absorption can lead to changes in dimensions and physical properties.

Dimensional Stability: Nylon parts can swell due to moisture absorption, affecting precision in dimensions. For example, Nylon 6 can absorb up to 9.5% of its weight in moisture, which can lead to a dimensional change of up to 2%.

Mechanical Properties: Increased moisture generally improves impact resistance but can decrease tensile strength and stiffness. For instance, dry Nylon 6,6 has a tensile strength of about 12,400 psi, which can decrease with moisture.

Application Consideration: For applications requiring high dimensional stability, such as precision gears, nylons with lower moisture absorption like PA 12 (with a moisture absorption of approximately 1.5%) are preferable.

Temperature and Chemical Resistance of Different Nylons

Different nylon grades exhibit varying levels of temperature and chemical resistance, influencing their suitability for various applications.

- Temperature Resistance: High-temperature applications favor Nylon 4,6, which maintains properties up to 150°C, compared to Nylon 6,6 which starts losing strength above 100°C.

- Chemical Resistance: Nylon 6,6 offers good resistance to hydrocarbons, solvents, and chemicals, making it suitable for automotive fuel lines. In contrast, Nylon 6 is less resistant to strong acids and bases.

- Cost vs. Performance: High-performance nylons like Nylon 4,6 and PA 11, which offer better temperature and chemical resistance, typically come at a higher cost. For less demanding applications, Nylon 6 or 6,6 can be more cost-effective choices.

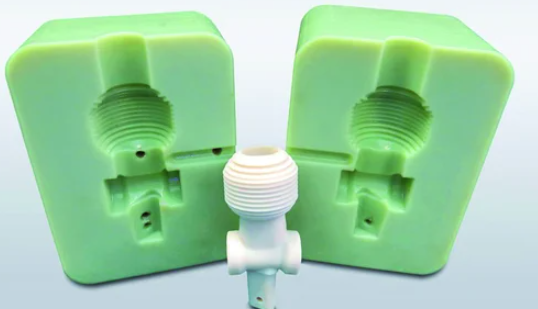

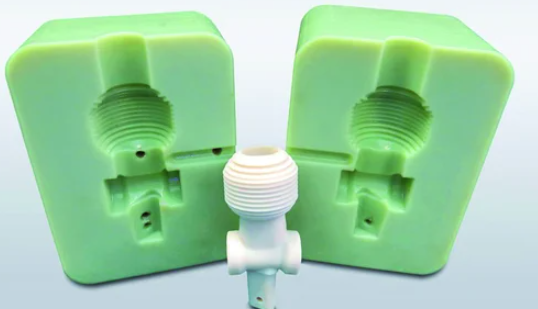

Processing Considerations for Nylon Injection Molding

Successful nylon injection molding requires careful consideration of material characteristics, machine settings, and part design to ensure high-quality output. Key factors include temperature control, moisture content, and mold design.

Optimizing Molding Conditions for Nylon Materials

Precise control over the molding process is crucial to capitalize on nylon’s properties.

Temperature Control: Nylon requires a uniform temperature to flow correctly. The melting temperature for Nylon 6, for instance, ranges from 220°C to 260°C. Inconsistent temperatures can lead to defects in parts.

Moisture Content: Proper drying of nylon before processing is critical. Nylon 6,6, for example, should have a moisture content below 0.2% to avoid hydrolytic degradation, which weakens the material.

Mold Temperature and Pressure: Mold temperature significantly affects the crystallinity of nylon. Higher mold temperatures, typically between 80°C to 90°C, enhance crystallinity, which in turn affects the mechanical properties. Also, applying the correct pressure ensures complete cavity filling and reduces defects.

Addressing Challenges: Warping and Shrinkage in Nylon Parts

Warping and shrinkage are common issues in nylon injection molding, influenced by material characteristics and processing parameters.

- Warping: Occurs due to uneven cooling or internal stresses. Reducing the temperature differential between the melt and the mold can minimize warping. For instance, using a mold temperature closer to 80°C can help reduce stress in Nylon 6 parts.

- Shrinkage: Nylon tends to shrink between 1% and 2%, depending on the grade and fillers. Consistent processing conditions and an accurate understanding of the material’s shrinkage rate are essential for achieving precise dimensions. For example, adding glass fibers can reduce the shrinkage rate of Nylon 6,6 from 1.2% to as low as 0.3%.

Enhancing Nylon Properties with Additives and Fillers

Integrating additives and fillers into nylon can significantly enhance its mechanical and thermal properties, making it suitable for a wider range of applications. This customization allows for improved performance in specific environments and applications.

Role of Glass Fibers and Mineral Fillers

Adding glass fibers and mineral fillers to nylon can dramatically improve its strength, stiffness, and heat resistance.

Glass Fiber Reinforcement: By adding glass fibers, typically in the range of 10% to 40% by weight, the tensile strength and stiffness of nylon can increase significantly. For example, 30% glass fiber-reinforced Nylon 6 can have a tensile strength of up to 18,000 psi, compared to 8,000 psi for unfilled Nylon 6.

Mineral Fillers: Minerals like mica or talc, when added to nylon, can enhance dimensional stability and reduce warpage. A 15% addition of talc in Nylon 6 can lead to a 50% reduction in shrinkage.

Impact of Additives on Mechanical and Thermal Properties

Various additives can tailor the properties of nylon for specific needs, from improving wear resistance to enhancing thermal stability.

- Wear Resistance: Additives like PTFE or silicone can significantly reduce the wear and friction coefficient of nylon. This is particularly beneficial in applications like gears or bearings.

- Thermal Stability: High-temperature stabilizers can increase the heat deflection temperature of nylon. For instance, certain additives can enable Nylon 6,6 to withstand temperatures over 150°C, making it suitable for under-the-hood automotive applications.

- Flame Retardants: For applications requiring fire resistance, adding flame retardants can make nylon self-extinguishing. The inclusion of 10% to 15% of a flame retardant can achieve a UL 94 V-0 rating for nylon.

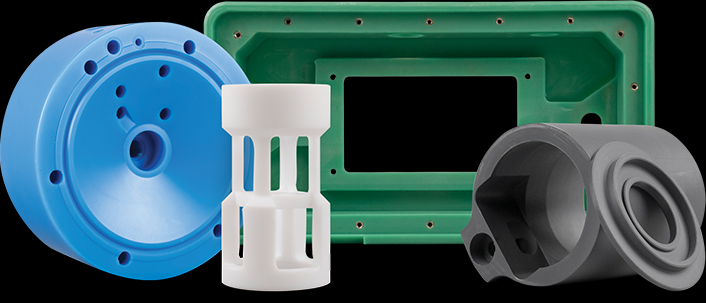

Case Studies: Successful Applications of Nylon in Injection Molding

Nylon’s versatility and superior properties have led to its widespread use in various industries, particularly in the automotive and consumer goods sectors. These case studies showcase the material’s adaptability and performance.

Automotive Industry: High-Performance Applications

The automotive industry extensively uses nylon for parts that require strength, heat resistance, and durability.

Engine Components: Nylon’s heat resistance makes it ideal for under-the-hood applications. For example, Nylon 6,6, reinforced with 30% glass fiber, is commonly used for engine covers, due to its ability to withstand temperatures up to 150°C and its excellent mechanical strength.

Fuel Systems: Nylon’s chemical resistance makes it suitable for fuel line connectors and fuel tanks. The use of Nylon 12 in fuel lines, owing to its low moisture absorption and excellent barrier properties, helps in reducing fuel permeation.

Cost Efficiency: Compared to metals, nylon reduces the weight of components, leading to better fuel efficiency. For instance, replacing metal in a car’s intake manifold with nylon can reduce its weight by up to 50%, enhancing overall vehicle efficiency.

Consumer Goods: Durability and Aesthetics Considerations

In consumer goods, nylon offers an ideal balance of aesthetics, durability, and cost-effectiveness.

Kitchenware: The use of nylon in kitchen utensils demonstrates its heat resistance and durability. For example, nylon spatulas can withstand high temperatures while being gentle on non-stick coatings.

Sporting Goods: Nylon’s impact resistance and strength find applications in sporting goods like helmet shells or racquet frames. The addition of glass fibers can increase the impact resistance and stiffness, making nylon ideal for protective gear.

Aesthetic Appeal: Nylon can be easily colored, which is advantageous for consumer products that require aesthetic appeal. For instance, high-quality, brightly colored children’s toys are often made from nylon due to its color stability and durability.