Air escapes an injection mold through designed venting channels and the natural gaps at mold parting lines.

The Problem of Trapped Air

In the world of injection molding, trapped air is a significant challenge that often plagues the production process. When plastic resin is injected into a mold, it displaces the air inside. If this air doesn’t find an escape route, it becomes trapped within the mold, leading to various issues in the finished product.

Causes of Trapped Air

- Injection Speed: High-speed injections can lead to air being trapped as the resin might not give the air sufficient time to escape. The ideal speed will largely depend on the material being used and the intricacies of the mold.

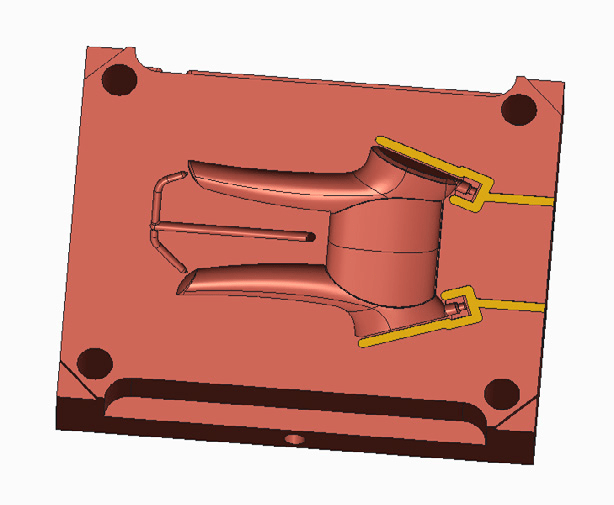

- Mold Design: If a mold is not designed with proper venting, air can easily become trapped. This is especially true for complex molds with intricate designs or multiple cavities.

- Viscosity of the Resin: Resins with higher viscosity can trap air more easily as they do not flow as smoothly. This makes it essential to choose the right resin and possibly adjust the processing temperatures.

- Improper Gate Location: The gate is where the resin enters the mold. If it’s placed incorrectly, it can lead to a turbulent flow of resin, increasing the chances of air entrapment.

More about Mold Design on Wikipedia

Consequences of Air Entrapment

- Short Shots: This is when the mold doesn’t fill completely, often due to trapped air preventing the resin from occupying the entire cavity. The result is a partial or incomplete part.

- Burn Marks: Trapped air can become compressed and heated. This superheated air can cause burn marks on the molded part’s surface.

- Structural Weakness: Parts with trapped air can have voids or pockets inside, leading to structural weaknesses and a higher likelihood of failure under stress.

- Aesthetic Flaws: Apart from burn marks, trapped air can cause other visual defects like blisters or deformities, making the part unsuitable for applications where aesthetics are crucial.

Mechanisms of Air Escape

In injection molding, the efficient escape of air is paramount for producing high-quality products. As plastic resin displaces the air inside a mold, this air must escape, or it can lead to defects in the finished product. Understanding the mechanisms through which air escapes is vital for optimizing the molding process.

Natural Air Venting

Natural air venting relies on the inherent properties and behaviors of the materials and mold design. Here are some aspects of this mechanism:

- Mold Parting Lines: In many cases, the mold’s parting lines, where two mold halves meet, provide a natural escape route for air. However, relying solely on parting lines may not be sufficient for complex molds.

- Resin Flow: As the resin flows into the mold, it pushes the air ahead of it. If the mold design facilitates a smooth, uninterrupted flow, the air can naturally move towards and escape through venting points.

- Porosity of the Mold Material: Some mold materials have natural porosity, which allows for minor air escape through the mold walls. But this method is not always reliable for significant air displacement.

Designed Venting Systems

For more control over air evacuation, many molds incorporate specially designed venting systems. Here’s what they entail:

- Vent Channels: These are narrow channels cut into the mold, specifically to allow air to escape. Their size and placement are crucial. If they’re too big, plastic might seep through them, causing flash. If too small or improperly placed, they may not effectively vent the air.

- Venting Inserts: In areas where traditional vents might be challenging to incorporate, venting inserts can be placed. These are porous materials that allow air to pass through but prevent the resin from seeping out.

- Vacuum Systems: Some advanced molds employ vacuum systems. These actively suck

Venting Solutions for Efficient Air Escape

For injection molding to be successful, efficient air escape is non-negotiable. Trapped air can lead to multiple defects in the final product. Therefore, effective venting solutions are a cornerstone of the molding process. Let’s delve deeper into the various venting solutions and their importance.

Types of Vents

To accommodate different mold designs and product requirements, there are several types of vents that can be incorporated.

Parting Line Vents

These are the most common vents used in injection molding. Parting line vents take advantage of the natural gap that exists where the two halves of a mold meet. By ensuring this gap is of an appropriate size, it can act as a vent, allowing displaced air to escape while the resin fills the mold.

Learn more about Parting Lines in Molding on Wikipedia

Blind Pocket Vents

Blind pocket vents are small, dead-end pockets or channels that are cut into the mold’s surface. They work by capturing trapped air as the resin flows into the mold. Once the air is trapped in these pockets, it prevents the air from creating defects within the main part. It’s a strategic way to manage air without letting it affect the product’s quality.

Venting Inserts

Venting inserts are specially designed components made from porous material. They are integrated into the mold and allow air to pass through their porous structure. However, they prevent the resin from escaping, ensuring that the mold fills correctly. This solution is particularly useful for molds where traditional venting channels might be challenging to implement.

Read more about specialized molding components on Wikipedia

Positioning and Size of Vents

The effectiveness of a vent isn’t just about its design but also about its position and size.

- Strategic Positioning: Vents should be positioned at locations where air is most likely to be trapped. This often includes the furthest points from the injection gate and areas with intricate designs or sharp turns.

- Optimal Size: The size of the vents is a delicate balance. They need to be large enough to allow air to escape efficiently but not so large that they cause resin flash. Typically, parting line vents are very thin, often between 0.0005 to 0.002 inches.

Materials and Venting

In injection molding, not all materials behave the same way. The type of material used can significantly influence the venting process. Material properties, especially viscosity, play a pivotal role in how air moves and escapes from the mold. Let’s understand the nuances associated with different materials and their impact on venting.

Impact of Material Viscosity on Venting

Viscosity refers to a material’s resistance to flow. In the context of injection molding, it determines how smoothly a resin fills the mold.

- High Viscosity Materials: Resins with high viscosity flow less easily. They tend to push air ahead of them rather than allowing it to escape around them. This can lead to increased chances of air entrapment unless adequate venting solutions are in place.

- Low Viscosity Materials: On the other hand, low viscosity resins flow more smoothly and can easily flow around trapped air, potentially sealing it inside the molded part. While they may seem easier to work with, they come with their own set of challenges and may require more precise venting solutions.

Materials Prone to Air Trapping

Certain materials, due to their inherent properties, are more susceptible to air trapping than others.

- Polyvinyl Chloride (PVC): PVC, especially when used in thicker sections, is notorious for trapping air. Special attention to mold design and venting is crucial when working with PVC.

- Polycarbonate: While offering excellent clarity and strength, polycarbonate’s flow characteristics can lead to air entrapment if not molded under optimal conditions.

- High-density Polyethylene (HDPE): HDPE, despite being a widely used material, can trap air, especially in intricate mold designs with tight corners or narrow sections.

Common Challenges and Solutions

The injection molding process, while efficient and versatile, is not without its challenges. Trapped air within the mold can lead to a plethora of issues, often compromising the quality of the final product. Recognizing these challenges and implementing effective solutions is essential for achieving consistent, high-quality outputs.

Overcoming Short Shots Due to Air Entrapment

Short shots are a common issue where the mold isn’t completely filled with resin, resulting in a partially formed part. The primary cause of short shots is often air entrapment.

- Solution: To combat this, molders can adjust the injection speed, ensuring that the resin is injected at a pace that allows air to escape. Additionally, the inclusion of more or larger vents, especially at the end of fill sections, can help. Analyzing the mold’s flow with computer simulations can also provide insights into potential problem areas and guide the design of effective venting solutions.

Explore more about Short Shots on Wikipedia

Addressing Burn Marks from Trapped Air

When air gets trapped and compressed within the mold, it can heat up and lead to burn marks on the finished product. These marks not only mar the appearance but can also affect the part’s structural integrity.

- Solution: To address this, it’s crucial to ensure proper venting, especially in intricate mold designs. Materials with higher mold temperatures can be particularly susceptible, so monitoring and adjusting the mold temperature might be necessary. In some cases, reducing the injection speed can also minimize the chances of overheating.

Ensuring Product Quality

Quality assurance in injection molding isn’t just about aesthetics; it’s about the functional and structural integrity of the molded parts.

- Solution: Regular inspection of molded parts, using tools like computerized tomography (CT) scanning or X-ray analysis, can identify internal defects caused by trapped air. Consistent mold maintenance, ensuring vents remain clear and undamaged, is another proactive measure. Finally, training machine operators to understand the nuances of materials and the molding process can result in more consistent quality.